Client Overview

A leading metal processing company in Kazakhstan, specializing in custom metal fabrication for various industries including construction, automotive, and industrial equipment manufacturing.

Challenge

The company needed to enhance its capabilities in processing long, large-diameter metal tubes with high precision and efficiency. Specifically, they required a solution for cutting tubes with the following specifications:

- Diameter: 40mm

- Length: 2000mm

- Wall thickness: 2mm

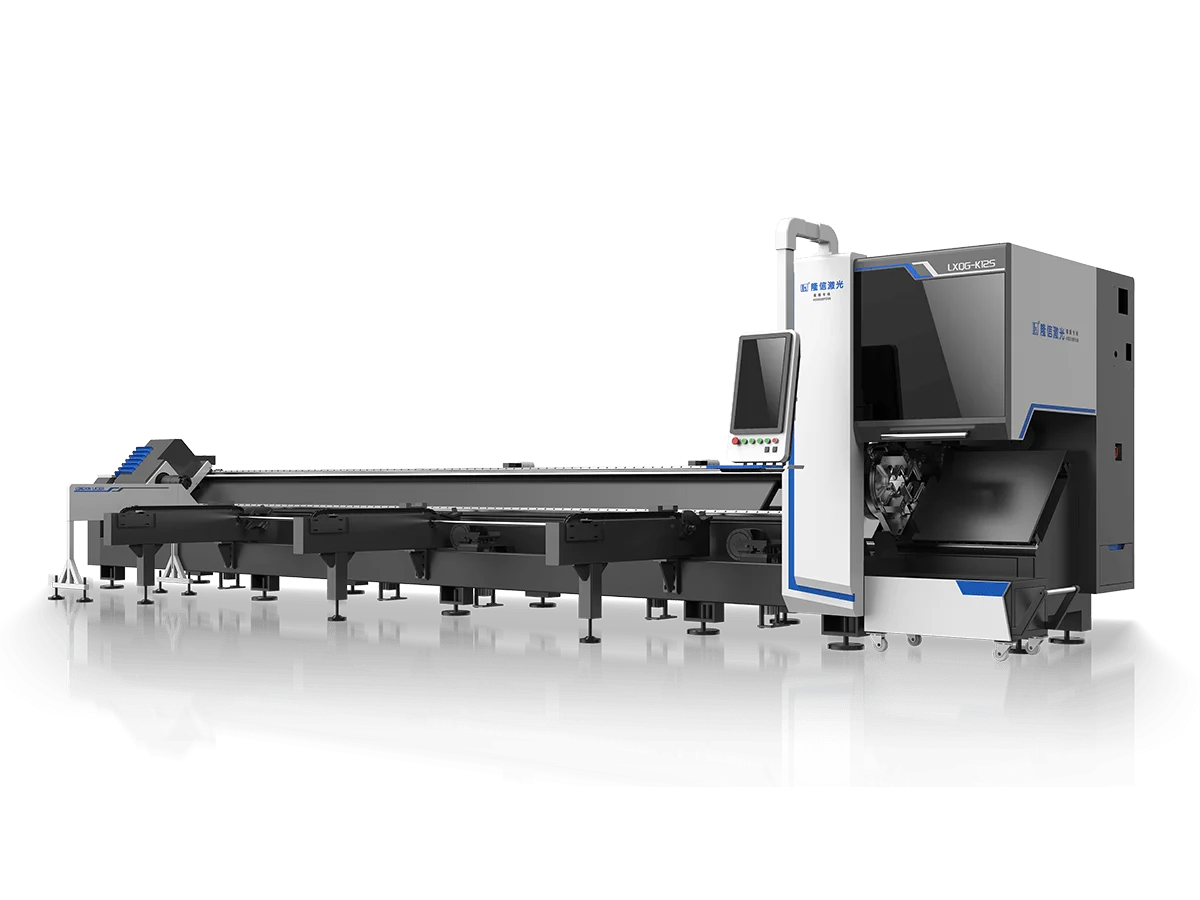

Solution: LX-K12s Laser Tube Cutting Machine

The company chose the LX-K12s laser tube cutting machine from Longxin Laser for its advanced features and ability to handle their specific requirements.

Key Features of LX-K12s

- Intelligent Cutting Technology

- Capability to process long tubes up to 12000mm

- Advanced control system for precise cutting

- Suitable for various materials including carbon steel, stainless steel, and aluminum

Implementation and Results

Machine Integration

- The LX-K12s was installed and calibrated by Longxin Laser’s technical team within two weeks.

- Operators received comprehensive training on the machine’s operation and maintenance.

- The production line was optimized to incorporate the new cutting capabilities.

Performance Improvements

- Precision and Quality

- Achieved cutting accuracy within ±0.1mm for 40mm diameter tubes.

- Significantly reduced post-processing requirements due to clean, precise cuts.

- Efficiency

- Cutting time for 2000mm long, 40mm diameter tubes reduced by 40% compared to previous methods.

- Ability to process complex cut patterns increased production flexibility.

- Material Utilization

- Material waste reduced by 15% due to optimized cutting patterns and reduced errors.

- Production Capacity

- Overall production capacity for tubular components increased by 30%.

Client Feedback

The Production Manager stated: “The LX-K12s has significantly improved our ability to handle large, long tubes with precision. Its intelligent cutting features have not only increased our output but also opened up new possibilities for complex designs we couldn’t achieve before.”

He added, “We’re particularly impressed with the machine’s consistency when cutting 2000mm long tubes. The ability to maintain high accuracy over such lengths has reduced our quality control issues and improved our final product quality.”

Future Plans

Based on the success with the LX-K12s, the company is exploring opportunities to expand its service offerings, particularly in sectors requiring precision-cut large tubular components. They are also considering investing in additional Longxin Laser equipment to further enhance their production capabilities.

Conclusión

The implementation of the LX-K12s laser tube cutting machine has enabled this Kazakhstan-based metal processing company to significantly enhance its production capabilities, especially in handling long, large-diameter tubes. The machine’s advanced features have not only improved efficiency and quality but also positioned the company to take on more complex and demanding projects in the future.