In a crucial period of transformation for large-scale mechanical equipment manufacturing, forward-thinking enterprises are leveraging intelligent technologies to reshape how large structural tubes and profiles are processed. The Longxin Laser LX-K35 emerges as a key enabler in this evolution, offering precision, stability, and automation for heavy-duty applications.

Challenges of Traditional Processing Methods

In the manufacturing of heavy mechanical components, conventional processing techniques face significant limitations when dealing with large-diameter pipes and complex profiles:

-

Mechanical stress from stamping or sawing often causes deformation.

-

Cumulative dimensional errors affect assembly precision in large structures.

-

Low production efficiency, with frequent secondary corrections increasing labor costs by up to 30%.

A Breakthrough for Large-Diameter Tube Processing

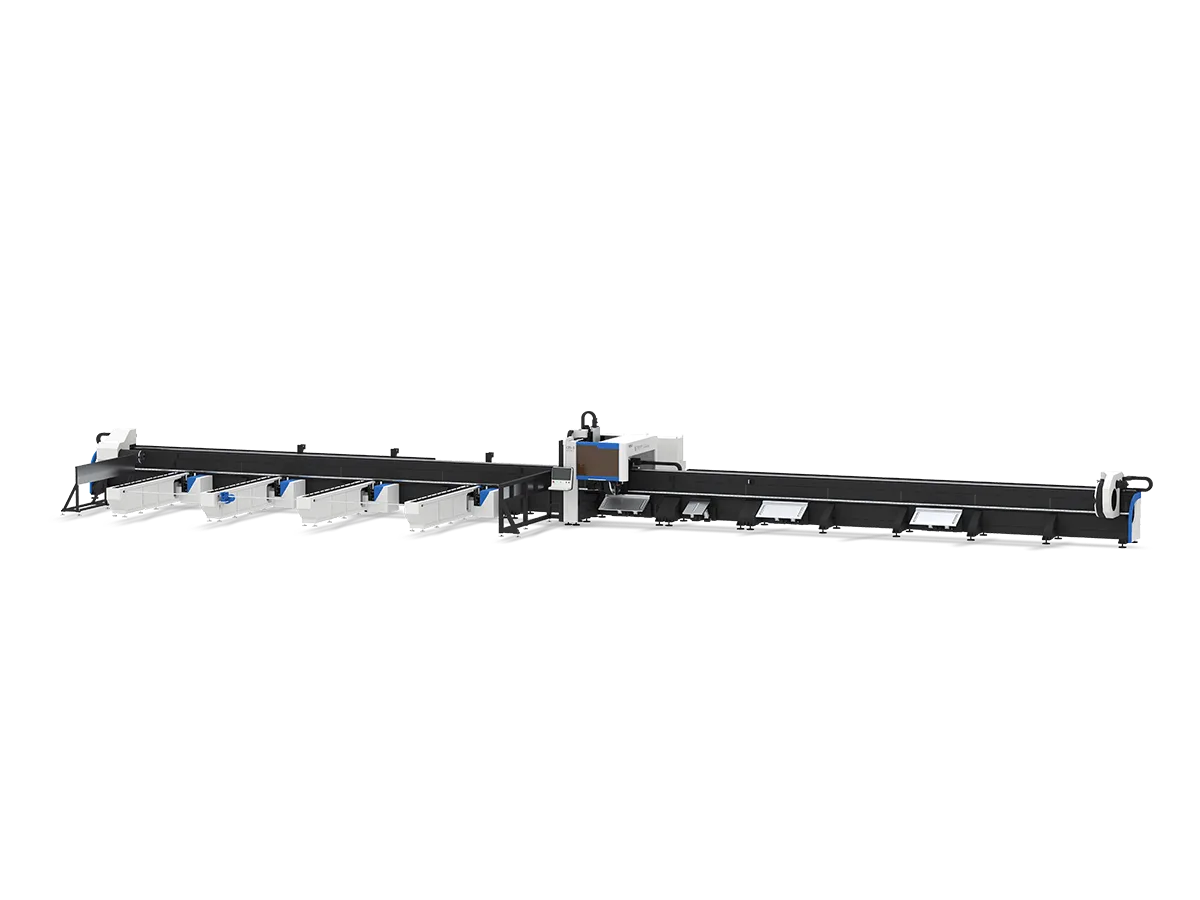

The LX-K35 3 chucks heavy duty fiber laser pipe cutting machine is designed to overcome these challenges with intelligent, high-performance solutions.

-

Stable Side-Mounted Bed Design: Enhances durability and protects the frame and guide rails from loading/unloading collisions.

-

Automated Loading System: Supports round and square tubes as well as complex profiles such as channel steel, angle iron, and H-beams.

Precision Cutting That Minimizes Post-Processing

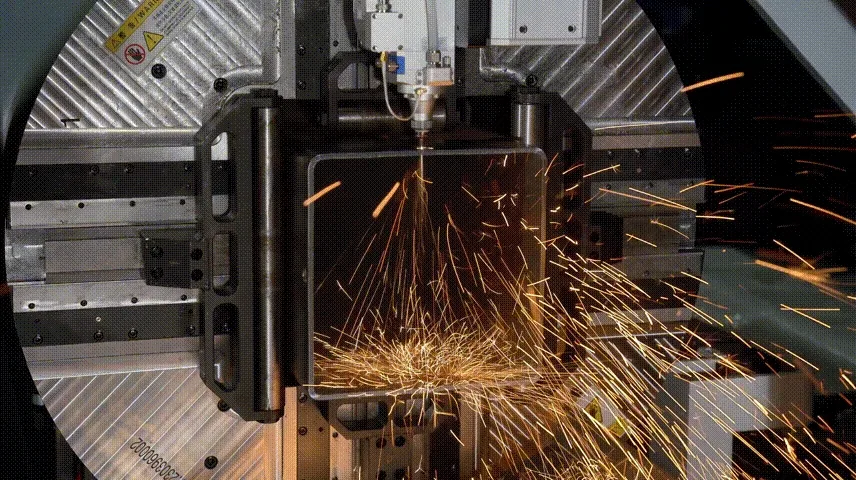

The LX-K35 features an innovative three-chuck system that enables flexible clamping and directional switching for zero-tail cutting of heavy-duty pipes and profiles. This design ensures precise, clean cuts, significantly improves material utilization, and reduces downstream processing costs.

Versatility Meets Efficiency

Capable of handling pipe diameters from 40 mm to 360 mm, the LX-K35 integrates automatic feeding and smart nesting software, enabling streamlined, high-efficiency operations. Compared to traditional methods, it delivers a significant productivity boost while simplifying daily production management.

Powering Smart Manufacturing Across Industries

As a “universal tool” in the mechanical manufacturing sector, the Longxin Laser LX-K35 has been widely adopted in industries such as:

-

Mining Equipment

-

Agricultural Machinery

-

Rail Transit

-

Construcción naval

Looking ahead, Longxin Laser will continue driving innovation and pushing the boundaries of heavy-duty laser pipe cutting. The K35 represents not just a tool—but a force behind China’s growing intelligent manufacturing capabilities.

Laser-driven intelligence, built for the future.