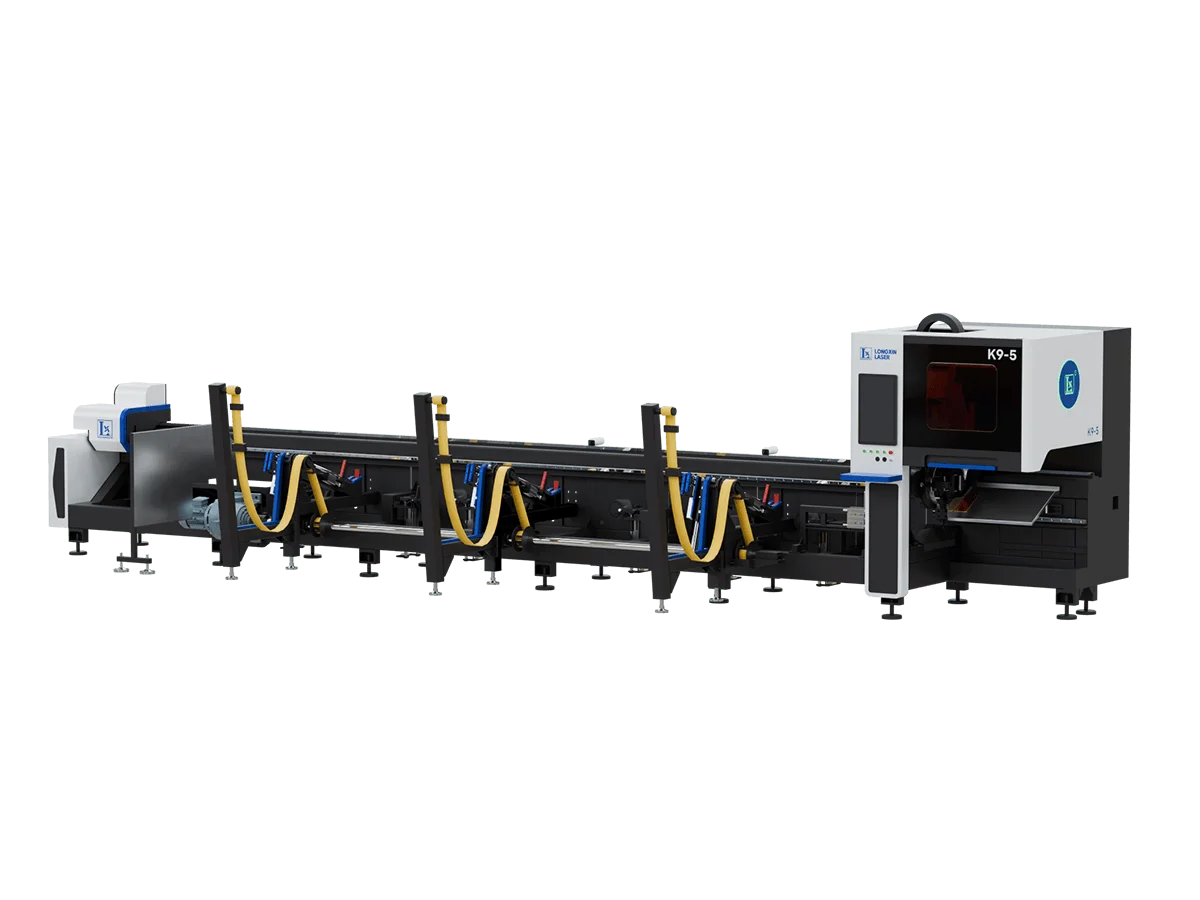

Longxin Laser’s Fifth-Generation LX-K9-5 Machine Outperforms Previous Model in Real-World Speed Test

Longxin Laser recently conducted a real-world cutting speed comparison between its newly upgraded LX-K9-5 High-Speed Laser Pipe Cutting Machine and the previous fourth-generation model. The test focused on arc-shaped hole punching on round tubes — a common and critical process in metal pipe fabrication.

Test Parameters:

-

Pipe Diameter: 35 mm

-

Wall Thickness: 0.8 mm

-

Cutting Process: Saddle cut at the tube end + 4 circular holes

-

Quantity: 6 pipes

Results:

-

Fifth-Generation K9:

⏱️ Completed in 20.56 seconds -

Fourth-Generation K9:

⏱️ Completed in 24.52 seconds

The new generation machine cut the same number of tubes approximately 16% faster, and when projected over continuous production cycles, this equates to a 20% year-on-year increase in overall capacity.

This comparison highlights the ongoing evolution of Longxin’s pipe cutting solutions — faster, more precise, and built for high-volume production environments. As global demand for efficient metal processing grows, Longxin continues to push the limits of speed, automation, and intelligent manufacturing.