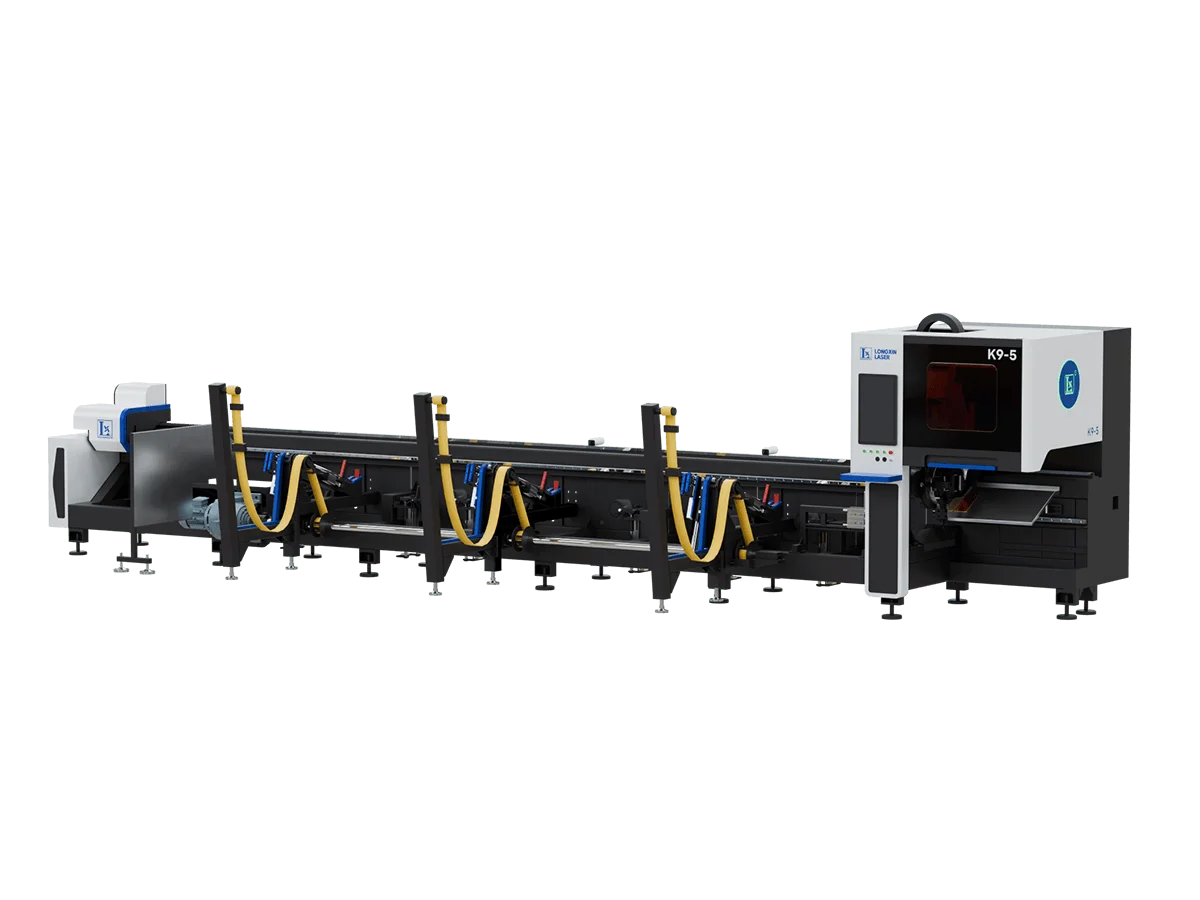

Longxin Laser has officially released its fifth-generation slag-free cutting technology, featured in the latest model LX-K9-5 Laser Pipe Cutting Machine. This new innovation introduces a cutting-edge solution for achieving residue-free internal pipe cutting — a game-changer for industries that demand high cleanliness and precision.

What is Slag-Free Cutting?

Unlike traditional laser pipe cutting methods that often leave behind molten slag inside the tube, the LX-K9-5 achieves near-zero internal residue through an advanced clean-cutting process. This innovative approach ensures that the inner wall of the pipe remains clean during cutting, eliminating the need for secondary cleaning and greatly improving the quality of the finished parts. It’s a cleaner, more efficient solution that also supports environmentally responsible manufacturing.

Key Advantages

-

Internal Slag-Free Cutting: Clean inner tube walls, with no need for secondary cleaning

-

Recyclable Deslagging Fluid: Environmentally responsible and reduces operating costs

-

Supports Multiple Materials: Ideal for aluminum tubes, stainless steely carbon steel

-

Complies with Green Production Standards: Reduces waste and supports sustainable manufacturing

-

Precision Cutting + Real-Time Deslagging: Maintains cutting quality while eliminating internal slag in one step

Ideal for High-Cleanliness Industries

This technology is particularly suitable for industries that demand residue-free internal surfaces, such as:

-

Medical Equipment Manufacturing

-

Home Appliance Tubing

-

Food-Grade and Cleanroom Applications

By integrating cutting and synchronous slag removal, the LX-K9-5 not only improves product quality but also supports the transition toward environmentally compliant, high-efficiency production lines.