1. Laser Cutting Basics: Understanding the Fundamentals

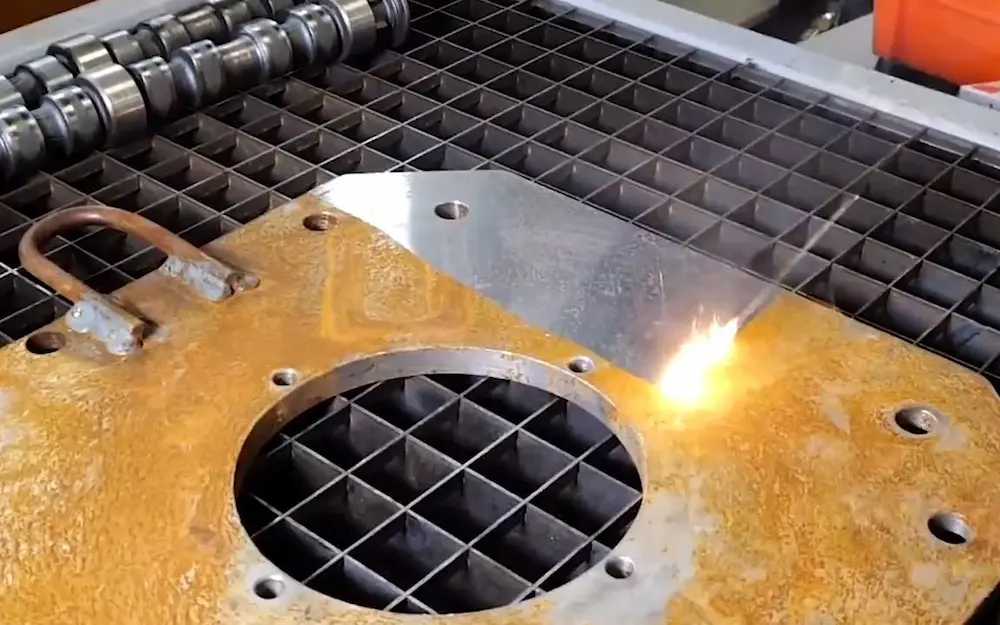

What is Laser Cutting?

Think of laser cutting like using a super-precise, high-powered magnifying glass to focus sunlight. Just as a magnifying glass can burn paper by concentrating light, a laser cutter uses a focused beam of light to cut through materials. The main difference? It’s thousands of times more powerful and precisely controlled.

Key Concepts:

- A focused beam of light acts as a “knife”

- Heat from the laser melts or vaporizes material

- Computer control ensures precision

- Works on various materials (wood, plastic, metals)

Why is Aluminum “Tricky” to Cut?

Aluminum presents unique challenges compared to other materials, much like trying to cut through a mirror that also conducts heat like a cooking pan.

Main Challenges:

- High reflectivity (up to 92% of light gets reflected)

- Excellent heat conductivity (spreads heat quickly)

- Lower melting point than steel (660°C/1220°F)

| Material | Reflectivity | Heat Conductivity | Melting Point |

|---|---|---|---|

| Aluminium | Very High | Excellent | Lower |

| Steel | Medium | Moderate | Higher |

| Tembaga | High | Excellent | Higher |

Common Pitfalls for Beginners

Insufficient Power

- Symptoms: Incomplete cuts, scorching

- Solution: Adjust power settings based on material thickness

Poor Heat Management

- Symptoms: Warping, melted edges

- Solution: Proper cooling and speed control

Surface Quality Issues

- Symptoms: Rough edges, discoloration

- Solution: Optimize focus and assist gas settings

2. Choosing Your Equipment: Laser Cutter Selection Guide

CO2 vs. Fiber Lasers

CO2 Lasers:

- Budget-friendly option

- Best for thin aluminum (up to 1/8 inch)

- Lower operating costs

- Slower cutting speeds

Fiber Lasers:

- Professional-grade choice

- Cuts thicker aluminum (up to 1/2 inch)

- Higher initial investment

- Faster cutting speeds

Equipment Selection Criteria

1. Budget Range

- Entry-level: $5,000-15,000

- Professional: $15,000-50,000+

2. Usage Scenarios

- Hobby/Small Business

- Production Workshop

- Industrial Manufacturing

3. Required Features

- Cutting bed size

- Automation needs

- Software compatibility

3. Practical Guide: Starting Your First Cut

Critical Parameters

| Thickness | Speed (IPM) | Power (%) |

|---|---|---|

| 0.5mm | 300-400 | 60-70 |

| 1.0mm | 200-300 | 70-80 |

| 2.0mm | 100-200 | 80-90 |

Troubleshooting Guide

Common Issues and Solutions:

- Incomplete cuts: Increase power/reduce speed

- Rough edges: Adjust focus/speed

- Warping: Improve cooling/adjust parameters

- Discoloration: Optimize assist gas flow

Pro Tips:

- Start with simple shapes

- Keep detailed records of successful settings

- Clean equipment regularly

- Practice on scrap material first

Remember: Success in laser cutting aluminum comes from understanding the basics, choosing the right equipment, and following proper procedures. Start small, be patient, and gradually work up to more complex projects as you gain experience.

Closing Thoughts

Cutting aluminum with a laser is possible but comes with its own set of challenges. You need to understand the right techniques and equipment to get the job done right. Choosing the suitable laser and knowing how to tackle aluminum’s unique properties can make all the difference in your projects. With the right approach, you can achieve clean cuts and impressive results.