Mesin pemotong pipa laser tugas berat

LX-K24

- Full-stroke closed precision chuck

- Intelligent cutting system, high versatility

- Extremely short tail, cross-cutting, saving pipe material: tail ≥ 45mm

- Support cutting pipe diameter range: ∅15mm-240mm □ 15*15 – 240*240mm

- Special-shaped pipe circumference ≤ ∅240mm (special-shaped pipe cutting needs to consult our company)

- Intelligent production, reduced labor, high cost performance

- Servo follow-up support, good support

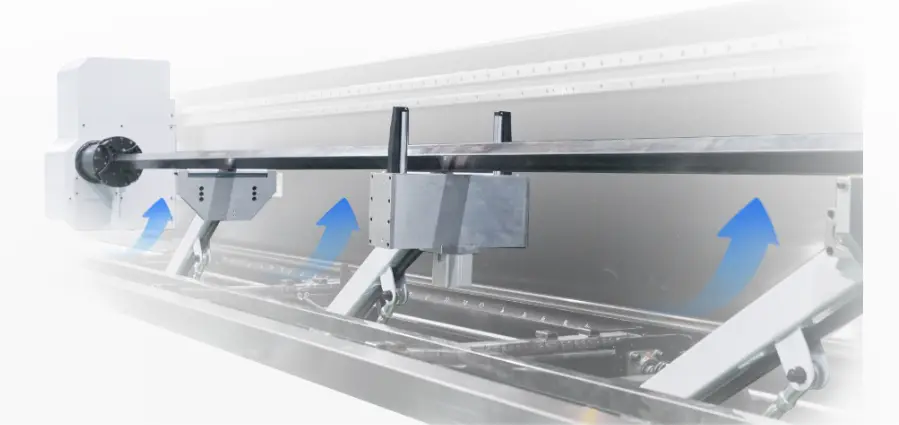

Pipe turning support device

A standard 1.2-meter material support plate is provided for holding and receiving materials before unloading the finished cut pieces. This significantly enhances the stability of tube cutting and prevents potential hazards caused by falling materials.

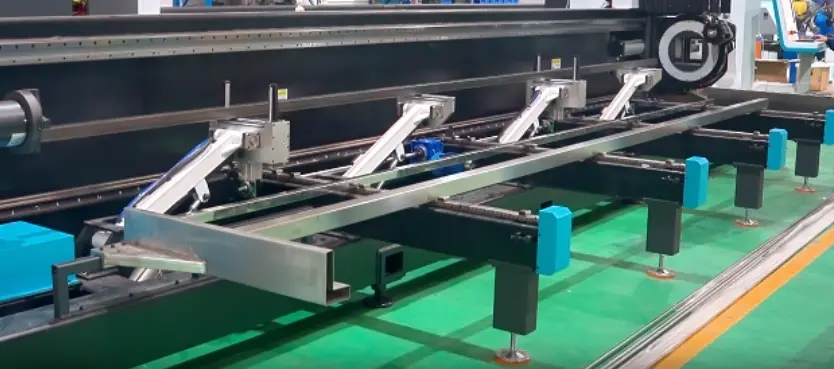

Servo Follow-Up Material Support System

A servo fllow-up support device is used to provide real-time lifting and support for the tubes during processing, significantly enhancing cutting stability and precision.

Selection of Semi-Automatic Feed Racks

Using a semi-automatic loading rack allows for the effortless conveyance of large quantities of heavy metal tubing, enabling continuous 24-hour operation.

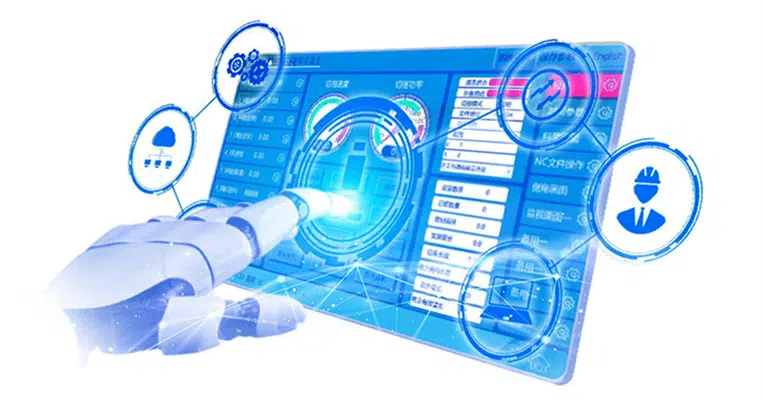

Intelligent CNC system specifically designed for pipe cutting

The system features a visual operation screen, easy parameter adjustments, and a wide range of functions. It supports multi-level perforation, intelligent tool retraction, automatic edge detection, and intelligent nesting, among other customizable features.

Memotong sampel

- Model:

- Kekuatan laser:

- Memotong Diameter Tabung bulat:

- Memotong Diameter tabung persegi:

- Memotong panjang tabung:

- Akurasi pemrosesan:

- Dimensi:

- Berat:

- Jenis Tabung Pemotong:

- Bahan Pemotongan: