Laser rust removal work is revolutionizing how we tackle corrosion with cleaning lasers. This innovative method offers a fast, efficient, and eco-friendly solution to restore metal surfaces. Forget traditional methods that are messy and time-consuming. Laser technology precisely targets rust without damaging the underlying material. It’s ideal for various applications, from automotive to industrial equipment. Experience the benefits of cleaner surfaces and extended lifespan for your assets. Dive into the world of laser rust removal and discover why it’s the go-to choice for professionals seeking quality results.

Understanding Laser Rust Removal

Basics of Laser Cleaning

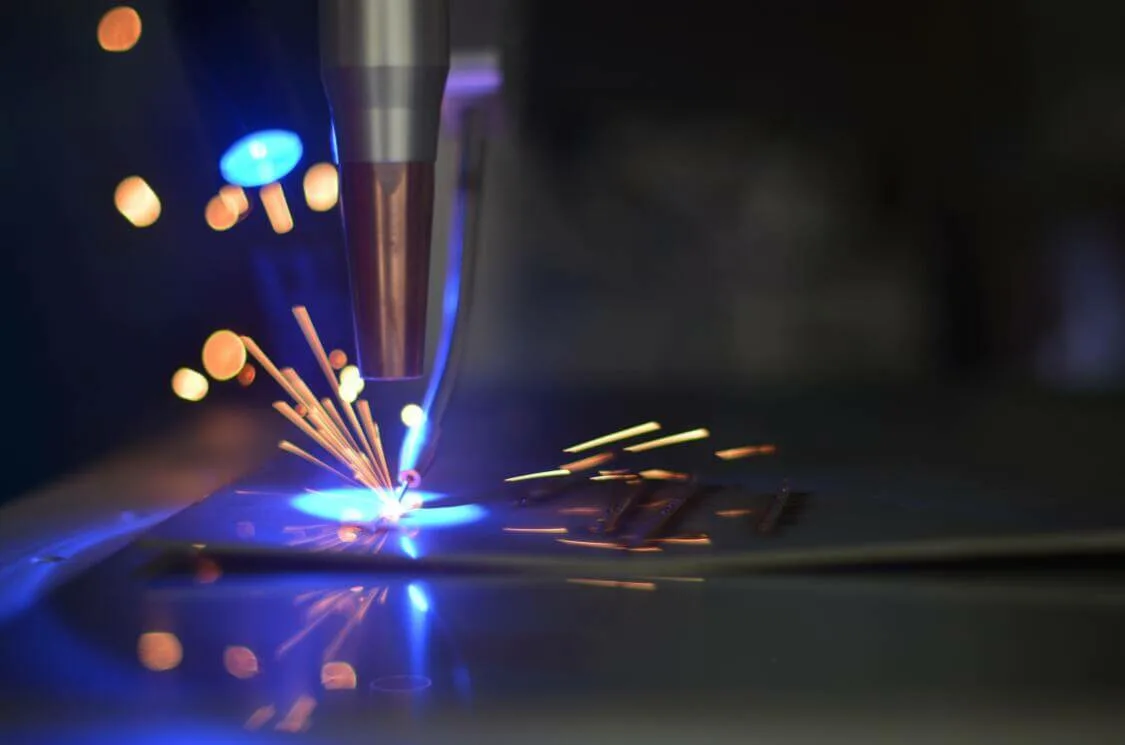

Laser rust removal is a modern method for cleaning metal surfaces. It uses focused light beams, such as laser cleaning, to remove rust and contaminants. Many rust removal systems exist, but laser rust cleaning offers precision and efficiency. Unlike traditional methods, it minimizes the risk of damaging the underlying material.

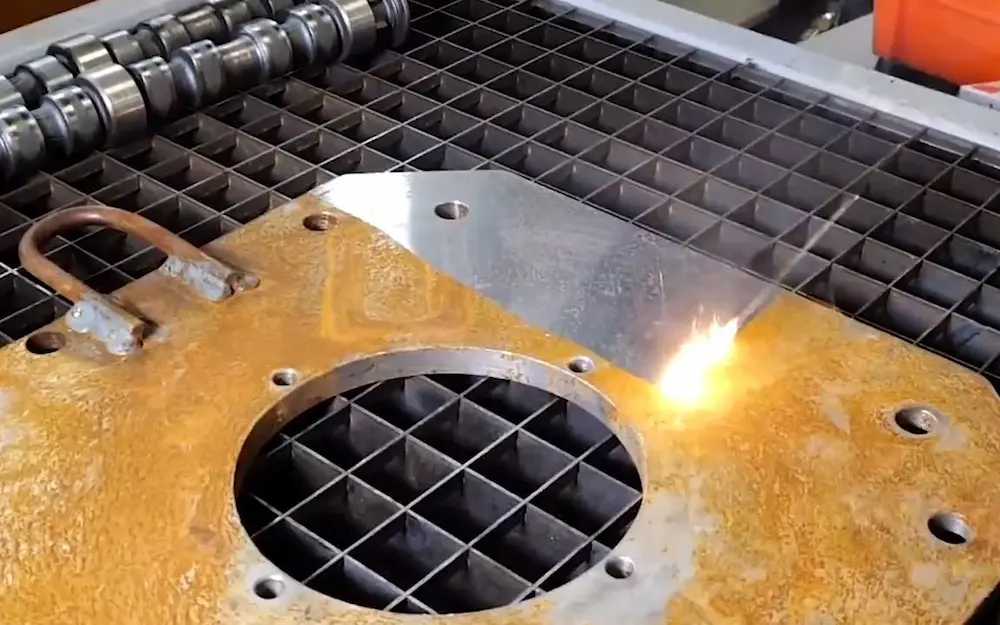

Portable laser rust removers are available for on-site jobs. They provide flexibility and convenience for various applications. Scale rust removal is effective in industrial settings, where heavy machinery often accumulates rust.

How Laser Technology Works

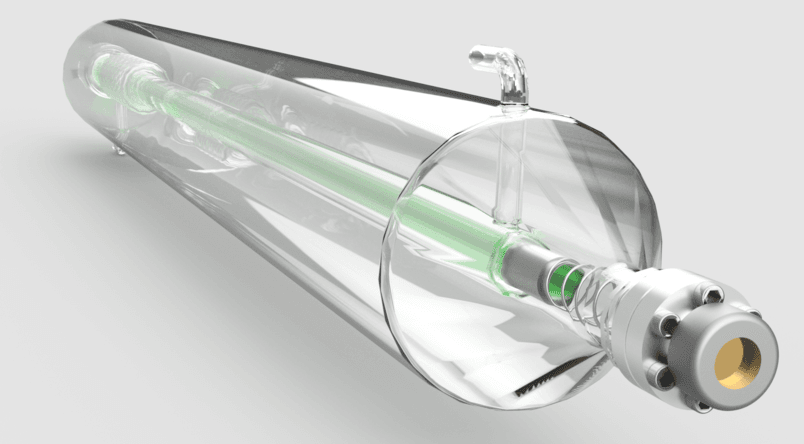

Laser technology operates by emitting concentrated light. This light heats the rust quickly, causing it to break down. The process generates minimal waste compared to chemical rust removers.

The laser rust removal machine can adjust its intensity based on the surface condition. Operators can control the depth of cleaning, ensuring safety for the base material. This adaptability makes it suitable for different types of metals.

Steps in the Cleaning Process

- Preparation: Clean the area around the rusted surface.

- Setup: Position the laser rust remover at the correct angle.

- Operation: Activate the machine and move it over the rusted area.

- Inspection: Check for remaining rust and repeat if necessary.

This step-by-step approach ensures thorough cleaning without damaging the metal underneath.

Benefits of Laser Technology

Environmental Advantages

Laser cleaning technology offers significant environmental benefits. This method reduces the need for harsh chemicals often used in traditional rust removal. It minimizes waste and pollution, making it a more sustainable option. The process generates little to no secondary waste. Therefore, it aligns with eco-friendly practices.

Reduction of Manual Labor

Laser treatment greatly decreases the amount of manual labor required for rust removal. Operators can use fiber laser machines that are efficient and precise. These machines handle tough jobs quickly, cutting down on time and effort. Workers spend less time scraping or sanding surfaces. This efficiency leads to increased productivity and lower labor costs.

Enhanced Workplace Safety

Laser solutions improve safety in the workplace. Traditional methods can expose workers to harmful substances and dust. In contrast, laser cleaning produces minimal debris, reducing inhalation risks. Operators work from a distance, lowering the chance of accidents. Enhanced safety measures create a healthier environment for employees.

Industrial Applications

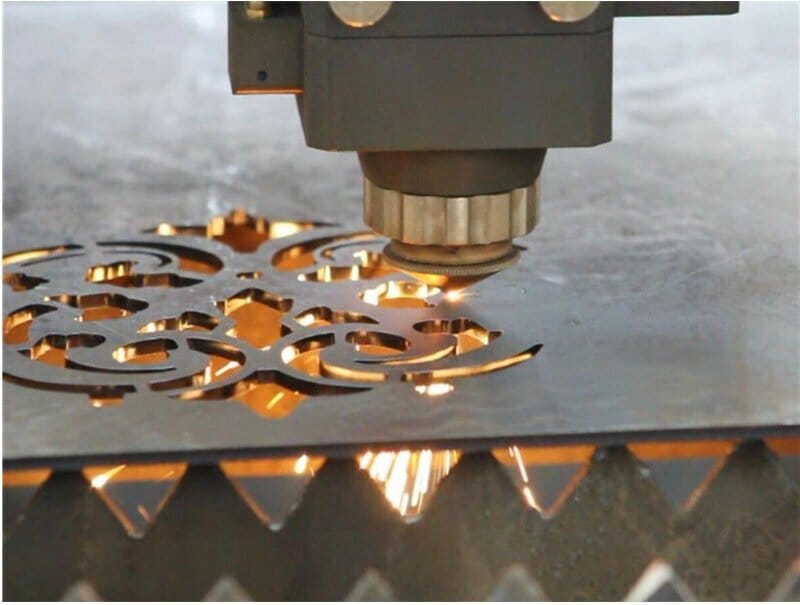

Pre-Welding Treatment

Laser rust removal plays a crucial role in pre-welding treatment. It prepares metal surfaces by eliminating rust and contaminants. This process ensures better adhesion during welding. Cleaner surfaces help prevent defects and improve weld quality. Many industries rely on this method to enhance production efficiency.

Pre-Coating Preparation

In pre-coating preparation, laser technology is essential. It removes rust and old coatings before applying new ones. This step is vital for achieving a smooth finish. Proper surface preparation increases the lifespan of coatings. Industries such as automotive and aerospace benefit from this application significantly.

Other Industrial Uses

Laser rust removal has various other industrial uses. It can clean machinery, tools, and equipment without damaging the underlying materials. This method is effective for maintaining power systems, ensuring they operate efficiently. It helps in restoring historical artifacts and structures by removing unwanted rust without harming the original material using laser.

Closing Thoughts

Laser rust removal is a game-changer for industries tackling corrosion. You’ve seen how it works and the benefits it brings. From efficiency to eco-friendliness, this technology is redefining maintenance practices. It’s not just about cleaning; it’s about preserving your assets and saving money in the long run.

Embrace laser technology in your operations. It’s time to elevate your rust removal approach. Don’t let corrosion hold you back. Explore how laser rust removal can transform your processes today. Your equipment deserves the best care, and this is it. Take action now and see the difference for yourself!