Hey there, laser enthusiasts! Today, we’re diving into the world of laser technology to compare two heavy hitters: CO2 lasers and fiber lasers. Whether you’re a business owner looking to invest in new equipment or just a curious tech buff, this breakdown will help you understand the key differences between these two laser technologies.

The Basics: What are CO2 and Fiber Lasers?

Before we jump into the comparison, let’s quickly recap what these lasers are all about.CO2 Lasers: These bad boys use carbon dioxide gas as the lasing medium. They’ve been around since the 1960s and have been workhorses in many industries.Fiber Lasers: The new kids on the block, fiber lasers use optical fibers doped with rare-earth elements to generate the laser beam. They’ve been gaining popularity since the early 2000s.

The Showdown: CO2 vs. Fiber

The main differences between CO laser cutting machine and fiber laser cutting machine are as follows:

1. Different light sources

CO2 laser cutting machine uses CO2 laser tube to generate laser beam. The working medium mainly uses CO2, O2, He, and Xe as auxiliary gas. The CO2 laser beam is reflected to the laser cutting head through the reflection and focusing lens.

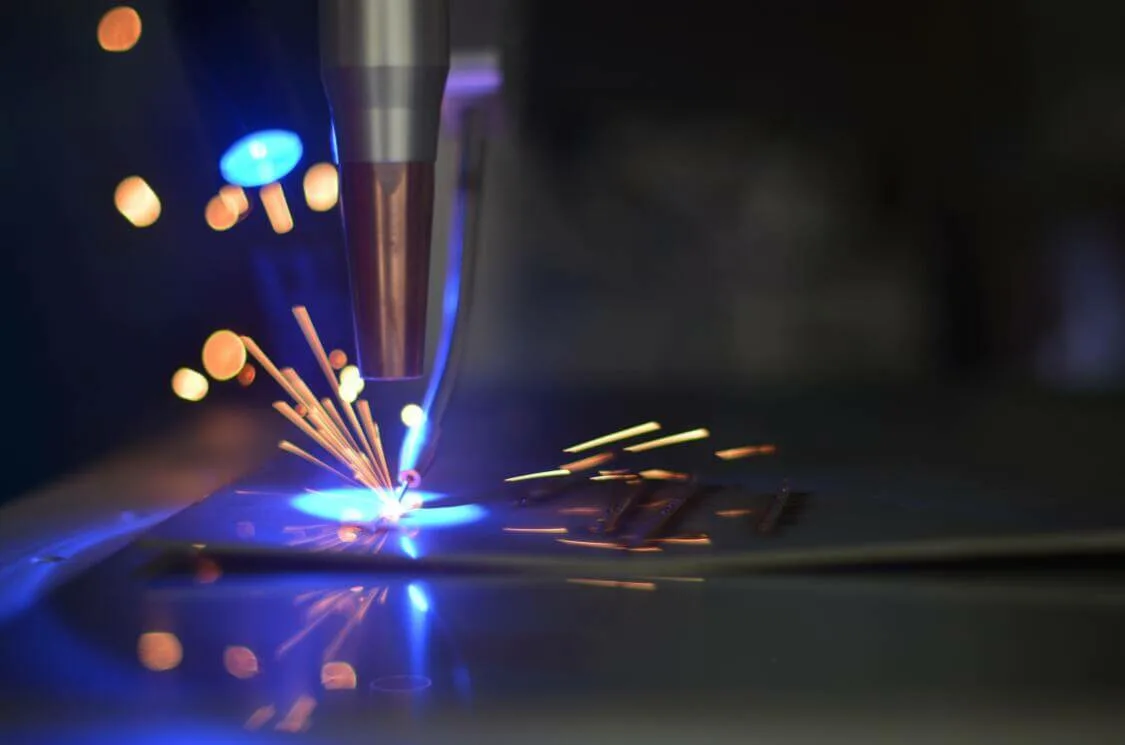

Fiber laser cutting machine generates laser beam through multiple diode pumps, and the laser beam is transmitted to the laser cutting head through soft fiber optic cable.

2. Different processing materials

The beam wavelength of CO2 laser is 10.64um, which is easily absorbed by non-metallic materials and is suitable for cutting non-metallic materials.

The beam wavelength of fiber laser is 1.064μm, which is 10 times shorter. Due to the small focal length, it is suitable for cutting metal materials.

3. Different production costs

CO2 laser cutting machine consumes a lot of gas when working, but its photoelectric conversion rate is only 8%~10%.

Fiber laser cutting machine consumes less during processing, and the photoelectric conversion rate can reach 25%-30%.

Fiber laser cutting machine is more energy-efficient than CO2 laser cutting machine.

4. Different maintenance costs

CO2 laser tubes have complex structures, fragile optical lenses, and are expensive. The cost of replacing consumables is high, and the maintenance cost is also high.

Fiber laser cutting is basically maintenance-free, and the wearing parts are durable and the replacement frequency is low.

5. Different cutting efficiency

CO2 laser cutting machines have a large beam diffusion during processing and are not suitable for large-scale processing. The processing speed of thick plates is slow.

The characteristics of fiber laser cutting machines are high laser beam density, high intensity, high brightness, high conversion rate, and fast processing speed.

6. Cutting Performance

Here’s where things get interesting:

- For thin metals, fiber lasers are lightning fast. They can zip through sheet metal like a hot knife through butter.

- CO2 lasers still hold their own when it comes to thicker materials, especially non-metals like wood and acrylic.

Motion Performance of Laser Processing Machines

While we’ve compared fiber laser and CO2 laser concepts, is this comparison alone sufficient when choosing a laser processing machine? The fiber and CO2 concepts are comparisons of the oscillator, which is just one component of laser processing machines. The drive axes, known as X, Y, and Z, are also significant components, and their motion and control performance are crucial factors.

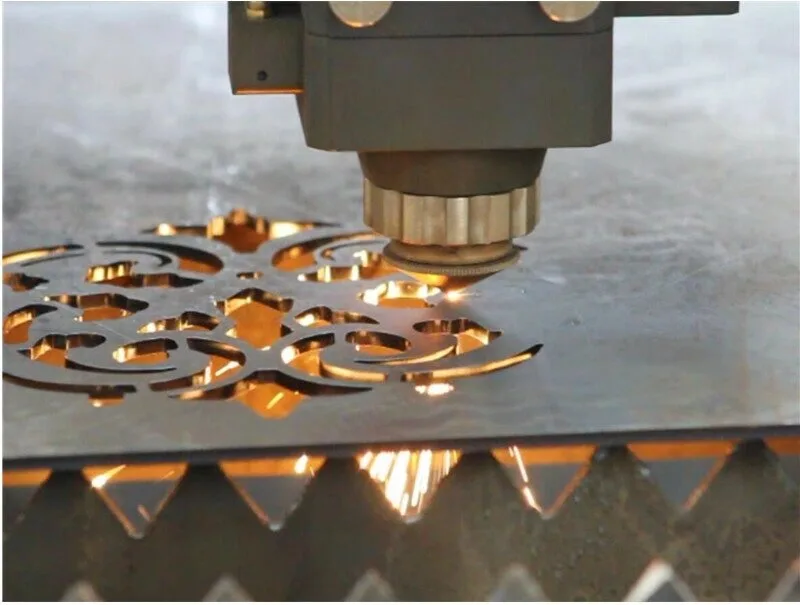

Laser processing machines cut various shapes beyond simple circles, squares, and rectangles, including complex contours, wedges, and embossed patterns. Even with high processing speeds, if the XY drive axes determining the cutting shape have poor motion performance, reducing processing time becomes impossible.

For instance, if a fiber laser machine cuts at 40m/min and a CO2 laser machine at 20m/min, does this mean the fiber laser will always process shapes in half the time? For complex shapes with numerous holes, the answer is no. To fully utilize the speed difference, improved drive axis motion performance is necessary, especially in acceleration and deceleration during cutting.

Comprehensive Capabilities of Laser Processing Machines

High acceleration and deceleration performance require a robust, high-rigidity frame to withstand the motion. Maintaining product processing accuracy needs an internal structure capable of controlling high motion performance. To maximize the laser processing capabilities of the oscillator, it’s essential to enhance the overall performance of the laser processing machine, including the drive axes.

The relatively simple composition of fiber laser processing machines means that manufacturers without extensive laser processing technology can produce machines of reasonable quality. Many components for fiber laser machines are readily available in the market, and machines assembled from these components can perform competitively. This accessibility is one reason for the recent proliferation of fiber laser machine manufacturers.

CO2 laser machines, however, require more specialized processing techniques, such as laser propagation, leading to more significant differences in features and performance between manufacturers. A true laser processing machine manufacturer should possess mature technology, capable of designing and producing both CO2 and fiber laser machines. Companies with processing technology accumulated from CO2 laser machine production and applied to fiber laser machine design and manufacturing are the ones needed in the future market.

Which One is Right for You?

While processing accuracy and quality are difficult to quantify, the best choice is a laser processing machine that consistently maintains high accuracy and quality with excellent motion performance. However, before deciding, carefully consider your processing needs. If you mainly work with thin plates, have high production volumes, and need to control processing costs, a fiber laser machine is ideal. For frequent processing of plates over 6.0mm thick or when specific quality standards are required, a CO2 laser machine may be more suitable. Remember that post-processing steps and manual operations can significantly increase overall processing costs.

- Go for CO2 if you work primarily with non-metals or need versatility across materials.

- Choose fiber if you’re focused on metal cutting or need high-speed, high-precision work.

- Consider your budget, both short-term and long-term.

When selecting a laser processing machine, consider not only the laser processing step but also make a comprehensive judgment from the perspective of your products and manufacturing process.

The Future of Laser Technology

The laser industry isn’t standing still. We’re seeing some exciting developments:

- Hybrid systems that combine CO2 and fiber laser technologies

- Advancements in beam quality and power output for both types

- Integration with AI for smarter, more efficient operations

Which One is Right for You?

Choosing between CO2 and fiber laser technology depends on your specific needs. Here are some quick tips:

- Go for CO2 if you work primarily with non-metals or need versatility across materials.

- Choose fiber if you’re focused on metal cutting or need high-speed, high-precision work.

- Consider your budget, both short-term and long-term.

Wrapping Up

Both CO2 and fiber laser technologies have their strengths, and the “best” choice depends on your unique situation. As technology advances, we might see these differences blur, but for now, understanding these distinctions can help you make an informed decision.Got any experiences with CO2 or fiber lasers? Drop a comment below – I’d love to hear your thoughts!Remember, whether you’re cutting, engraving, or marking, the right laser can make all the difference. Choose wisely, and may your cuts be ever precise!