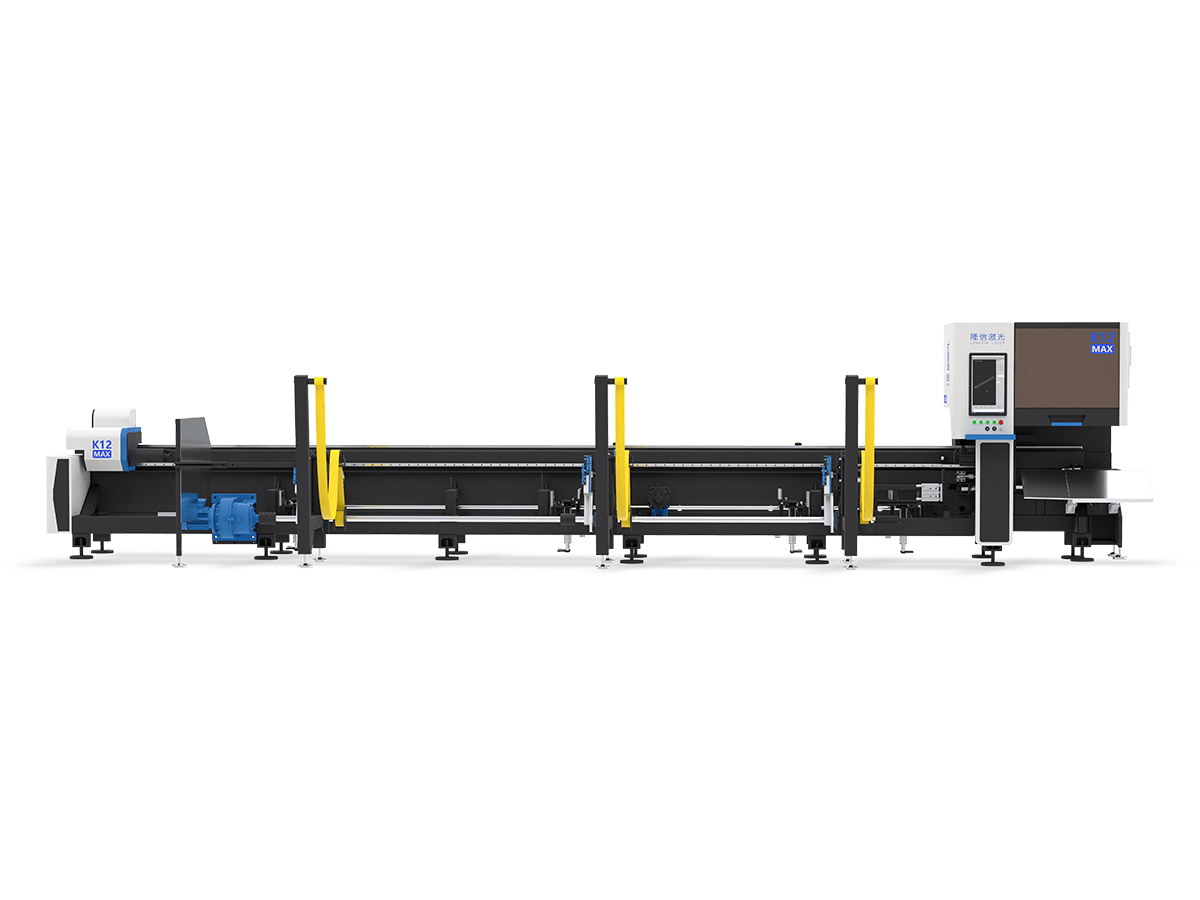

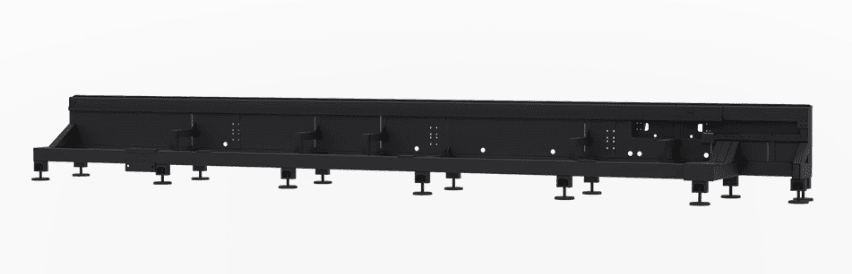

3d laser pipe cutting machine

LX-K12MAX

- Front card avoidance, shorter tail material

- Square hole chuck, wider range

- Side hanging structure, faster loading

- Optional follow-up loading and unloading/pneumatic loading and unloading

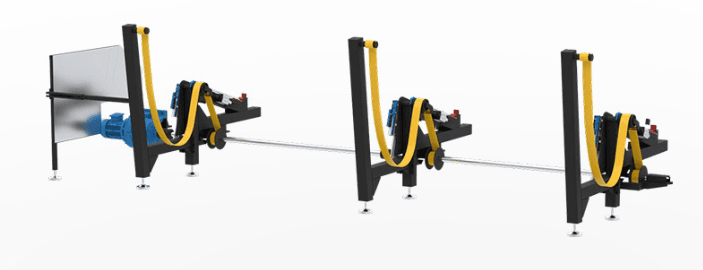

Fully automatic material rack

Automatic loading rack, capable of automatically selecting and loading tubes without the need for manual intervention, saving human resources.

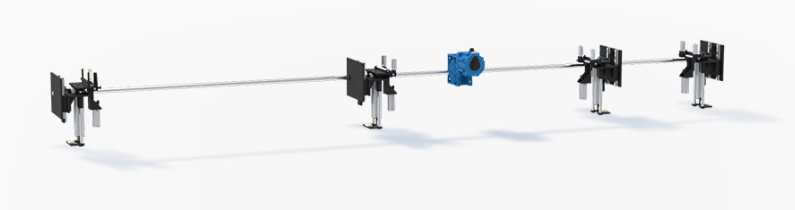

Follow-up material support

Adjustable vertical support based on the tube cutting conditions to prevent the tube from sagging and to improve cutting accuracy.

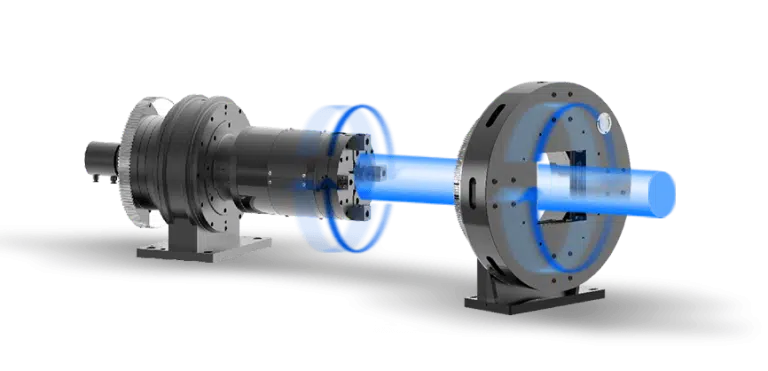

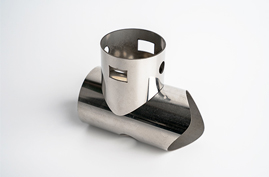

Minimal scrap material

Using advanced chuck forward-moving technology, in the final stage of tube cutting, the chuck holding the front end of the tube moves forward while the cutting head retracts to avoid interference, resulting in the shortest possible tailings.

Integrated side-mounted bed

Using an integrated quenching machine tool with a side-mounted chuck structure, the machine is compact, occupies a small footprint, and facilitates loading and maintenance.

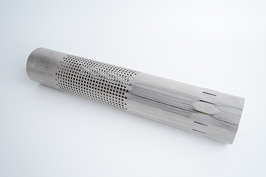

加工サンプル

- モデル:

- レーザーパワー:

- 切断径丸チューブ:

- 切断径のスクエアチューブ:

- 切削チューブの長さ:

- 精度の加工:

- 外形寸法:

- 重さ:

- 切削チューブタイプ:

- 切削素材: