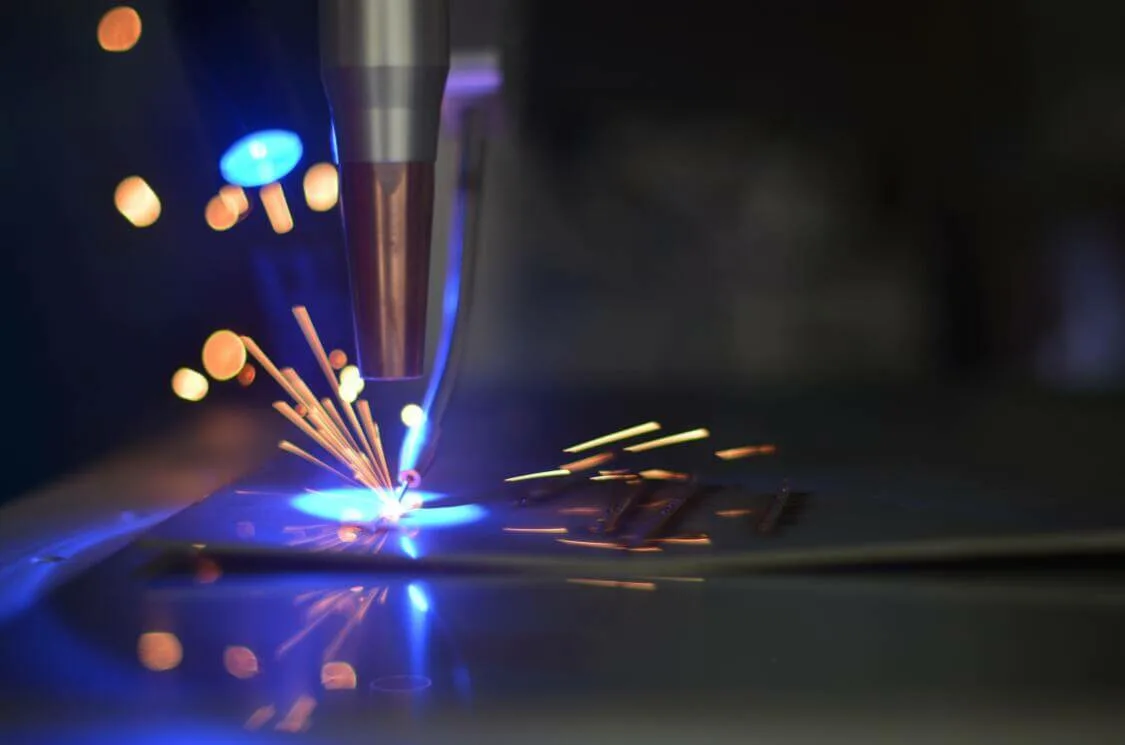

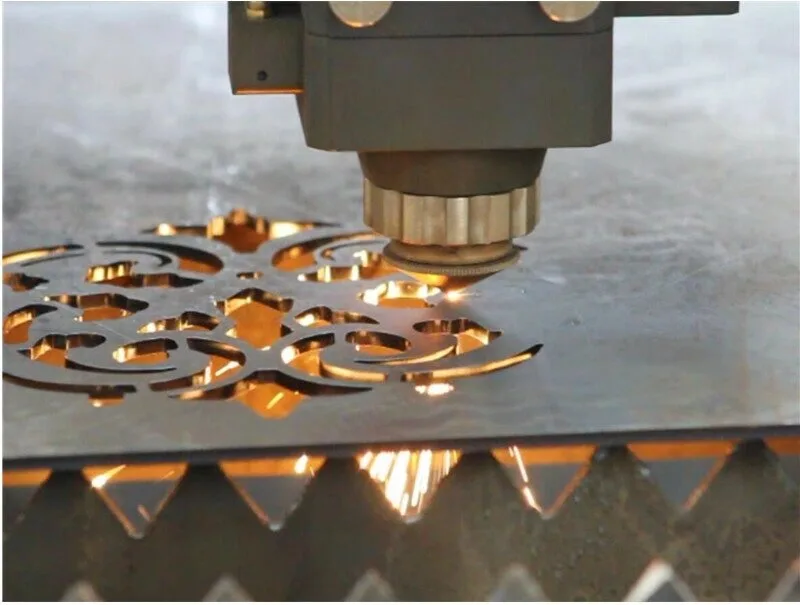

Laser cutting machines are fantastic tools for precision cutting, etching, and engraving a variety of materials. However, like any sophisticated equipment, they can run into issues that may affect their performance. Here are ten common problems that can cause laser cutting failures and how to avoid them.

1. Contaminated Protective Lenses

Touching protective lenses with bare hands or neglecting to clean off dust can significantly reduce their transparency, impacting the laser’s efficiency.

솔루션: Always clean and replace protective lenses properly. Use lint-free cloths and appropriate cleaning solutions to keep them spotless.

2. Dirty Guide Rails

Debris on the guide rails can cause the machine to malfunction, leading to broken gears or a jammed motor.

솔루션: Regularly inspect and clean the guide rails to ensure there are no foreign objects that could disrupt the machine’s operation.

3. Improper Height Calibration

Failing to verify that the laser head is positioned correctly over the material before calibration can result in damage.

솔루션: Always ensure the laser head is correctly positioned over the material before performing height calibration.

4. Neglecting Compressor Maintenance

Not draining the condensate from the compressor can allow moisture to affect the protective lenses, leading to machine failure.

솔루션: Regularly drain the condensate from the compressor and use high-quality compressors to avoid introducing oil or moisture into the system.

5. Unauthorized Disassembly of the Laser Head

Attempting to disassemble the laser head without proper knowledge can introduce dust and other contaminants, affecting performance.

솔루션: Leave the disassembly and cleaning of the laser head to professionals who have the proper tools and environment for the job.

6. Declining Laser Power

A drop in laser power can lead to poor cutting performance and incomplete cuts.

솔루션: Regularly check the laser power settings and replace components like the laser tube or power supply as needed.

7. Contaminated Optical Components

Dust and debris on optical components can obstruct the laser beam, reducing cutting efficiency.

솔루션: Clean all optical components regularly to ensure the laser beam remains unobstructed.

8. Unstable Voltage

Fluctuations in voltage can cause the laser to operate inconsistently, affecting cut quality.

솔루션: Use a stable power supply and consider installing a voltage regulator to maintain consistent power levels.

9. Excessive Cutting Speed

Cutting too quickly can lead to poor-quality cuts and incomplete sections.

솔루션: Adjust the cutting speed according to the material’s thickness and properties to ensure a clean cut.

10. Insufficient Auxiliary Gas Pressure

Low pressure in the auxiliary gas can result in incomplete cuts and rough edges.

솔루션: Ensure the auxiliary gas pressure is sufficient to assist in the cutting process effectively.

By addressing these common issues, you can significantly improve the performance and longevity of your laser cutting machine. Regular maintenance and proper handling are key to avoiding costly repairs and ensuring high-quality cuts every time.