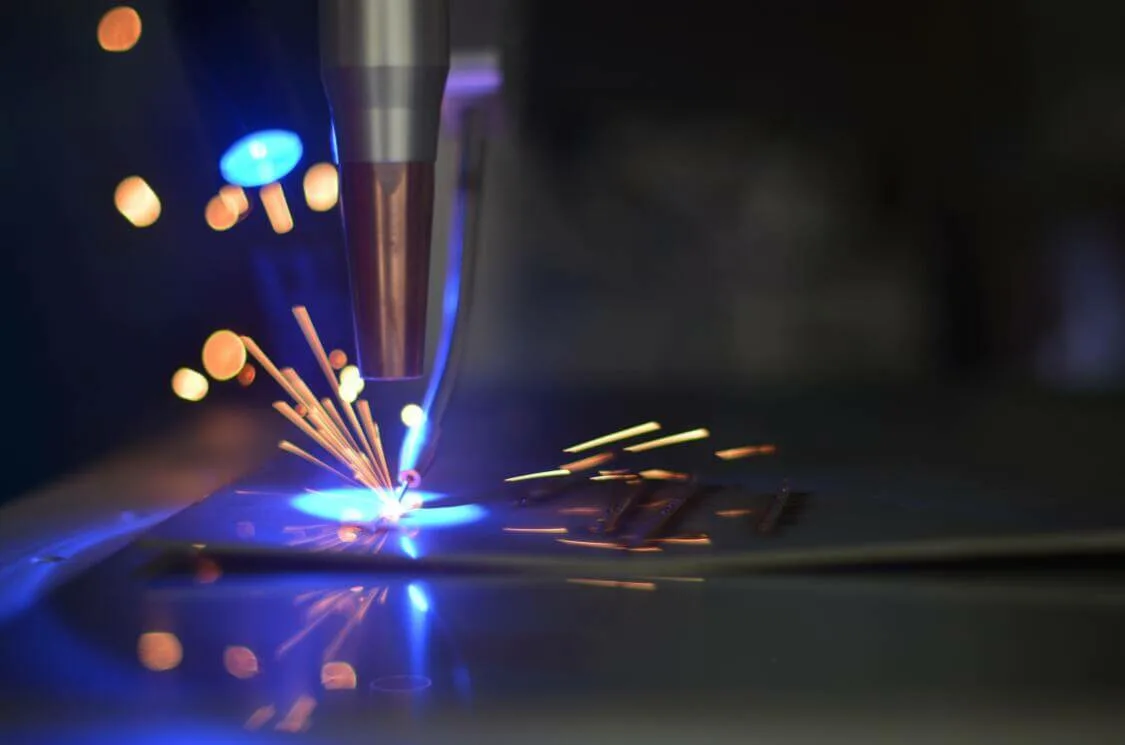

Selecting the right power for your laser tube cutting machine is essential to achieve the best results in your metal cutting projects. Whether you’re cutting thin tubes or thick plates, the power of your laser cutter can significantly affect the speed, quality, and cost of your operations. In this guide, we’ll break down the key factors to help you determine the ideal power level for your laser tube cutter.

Consider the Thickness of the Material

One of the most important factors in choosing the right power for your laser tube cutting machine is the thickness of the material you plan to cut:

- Thin Materials (0.5mm to 8mm): For cutting thin plates and tubes, a laser tube cutter with power below 1000W is generally sufficient. Machines in the 500W to 1000W range can handle these materials effectively.

- Thick Materials (above 10mm): If you need to cut thicker materials, you’ll require a more powerful laser. Machines with power above 2000W are suitable for these tasks, providing the necessary energy to cut through denser metals.

Evaluate Your Cutting Speed Requirements

The power of your laser tube cutting machine also impacts the speed at which you can complete your cuts:

- High-Speed Cutting: For operations where speed is critical, higher power lasers (2000W and above) are ideal. They can cut through materials quickly, boosting productivity.

- Precyzyjne cięcie: If your focus is on precision and cutting quality, moderate power levels (1000W to 2000W) might be more suitable. These machines offer better control and reduce the risk of overheating and material deformation.

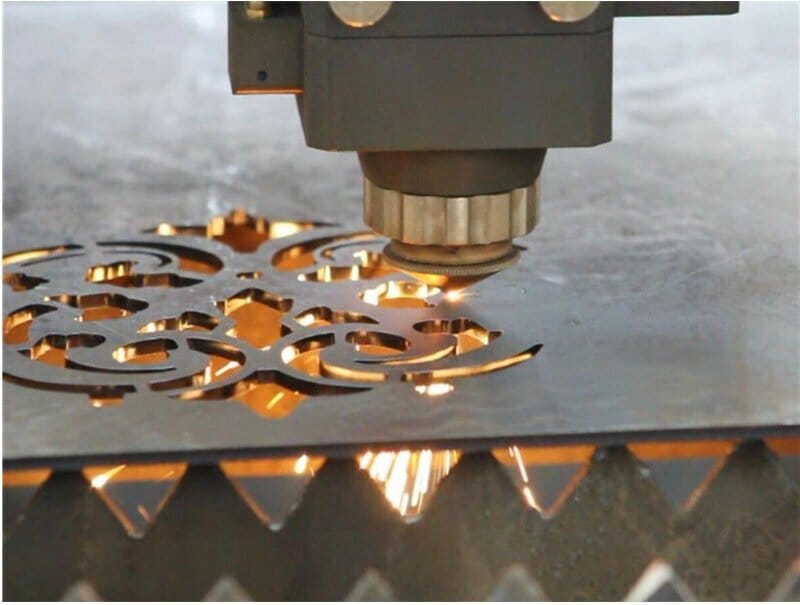

Assess the Desired Cutting Quality

Different applications require different levels of cutting quality, and the power of your laser tube cutter plays a role in achieving the desired results:

- High-Quality Cuts: For high-precision and high-quality cuts, choose a laser tube cutting machine with moderate power. Machines in the 1000W to 2000W range are often ideal for detailed work.

- Standard Quality: If your project does not require the highest precision, a lower power machine (below 1000W) can be a cost-effective choice while still delivering satisfactory results.

Factor in Processing Costs

Higher power laser tube cutters tend to be more expensive, both in terms of initial investment and operational costs:

- High-Power Machines: These come with a higher price tag and increased operational costs, such as energy consumption and maintenance. They are best suited for high-volume industrial applications where speed and material thickness justify the expense.

- Lower to Moderate Power Machines: More budget-friendly, these machines are perfect for smaller businesses or specialized tasks where high power isn’t necessary.

Making the Right Choice

To sum up, when choosing the power for your laser tube cutting machine, keep the following in mind:

- Material Thickness:

- Up to 8mm: 500W to 1000W

- Above 10mm: 2000W and above

- Cutting Speed:

- High-speed: 2000W and above

- Precision: 1000W to 2000W

- Cutting Quality:

- High-quality: 1000W to 2000W

- Standard quality: Below 1000W

- Cost Efficiency:

- Balance your need for power with your budget and operational costs.

By carefully considering these factors, you can select the best power level for your laser tube cutting machine, ensuring efficient, high-quality, and cost-effective cutting for your specific needs.