Introduction

In today’s fast-paced manufacturing environment, efficiency, precision, and speed are crucial to staying ahead. One company in Thailand, a key player in the metal processing industry, has embraced innovation by integrating Megrezlaser’s third-generation high-speed laser tube cutting machine, the K9Max, into their production process. This customer case study highlights how the K9Max machine helped revolutionize the company’s operations.

The Challenge

The metal processing industry in Thailand faces increasing demands for higher quality and faster production cycles, especially in industries such as construction, automotive, and furniture manufacturing. Our client, a leading metal fabricator, was struggling with:

- Slower cutting speeds.

- Limited precision on complex tube shapes.

- Increasing production costs due to older machinery.

- A growing need for better material utilization and less waste.

These challenges were limiting their ability to meet client demands and stay competitive in the market.

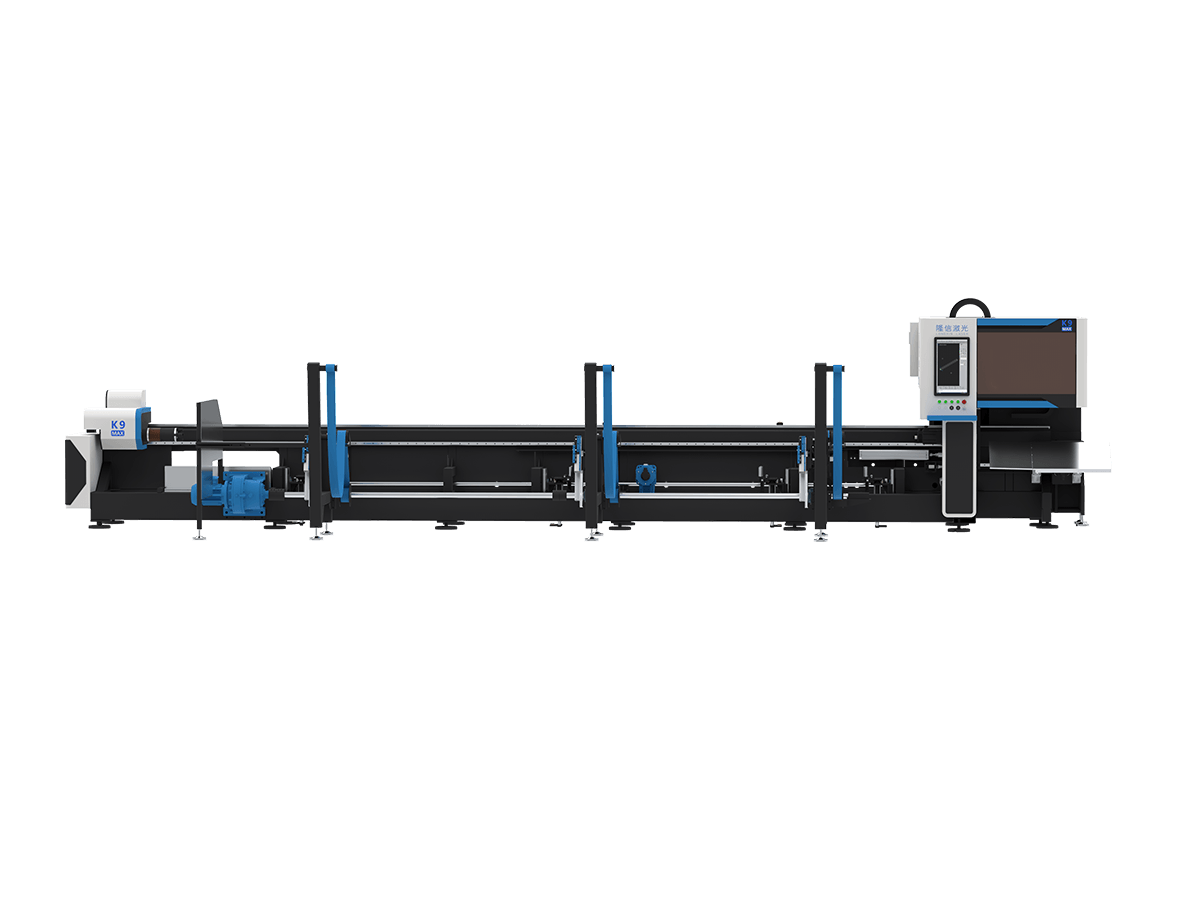

The Solution: K9Max Laser Tube Cutting Machine

The LX-K9MAX is equipped with cutting-edge features to address these challenges and more. The machine’s specifications include:

- Laser Power: 1500W-3000W, offering high cutting capacity for a wide range of materials.

- Cutting Diameter: Capable of handling round tubes with diameters from Φ10mm to 90mm and square tubes from ▢1010mm to 9090mm.

- Cutting Length: Can accommodate tubes up to 6500mm in length, allowing for the efficient processing of large orders.

- Accuracy: Ensures high precision with a processing accuracy of ±0,1 mm, resulting in minimal rework and waste.

- Materials: The K9Max is designed to cut various materials, including stainless steel, carbon steel, aluminum, copper, and iron, making it versatile for different industries.

- Dimensions & Weight: With dimensions of 9400mm x 1970mm x 1950mm and a weight of 2.75 tons, the machine is compact yet robust, fitting into the client’s existing production environment without major modifications.

Implementation and Results

The installation of the K9Max was completed seamlessly, with longxinlaser’s technical team providing expert support. Within the first month of use, the client experienced:

- Faster Production: Overall processing time was reduced by 30%, enabling the client to take on more orders and meet tighter deadlines.

- Improved Cutting Quality: The precision of cuts improved, leading to fewer errors, rework, and material wastage.

- Cost Savings: By increasing efficiency and reducing material waste, the client saw a 20% reduction in production costs.

Customer Testimonial

“Integrating the K9Max into our production line has been a turning point for us. The machine’s high-speed capabilities and precision have significantly improved our output and quality. We can now handle larger orders with tighter deadlines without sacrificing quality. longxinlaser’s support has been exceptional throughout the process, and we look forward to continuing our partnership.”