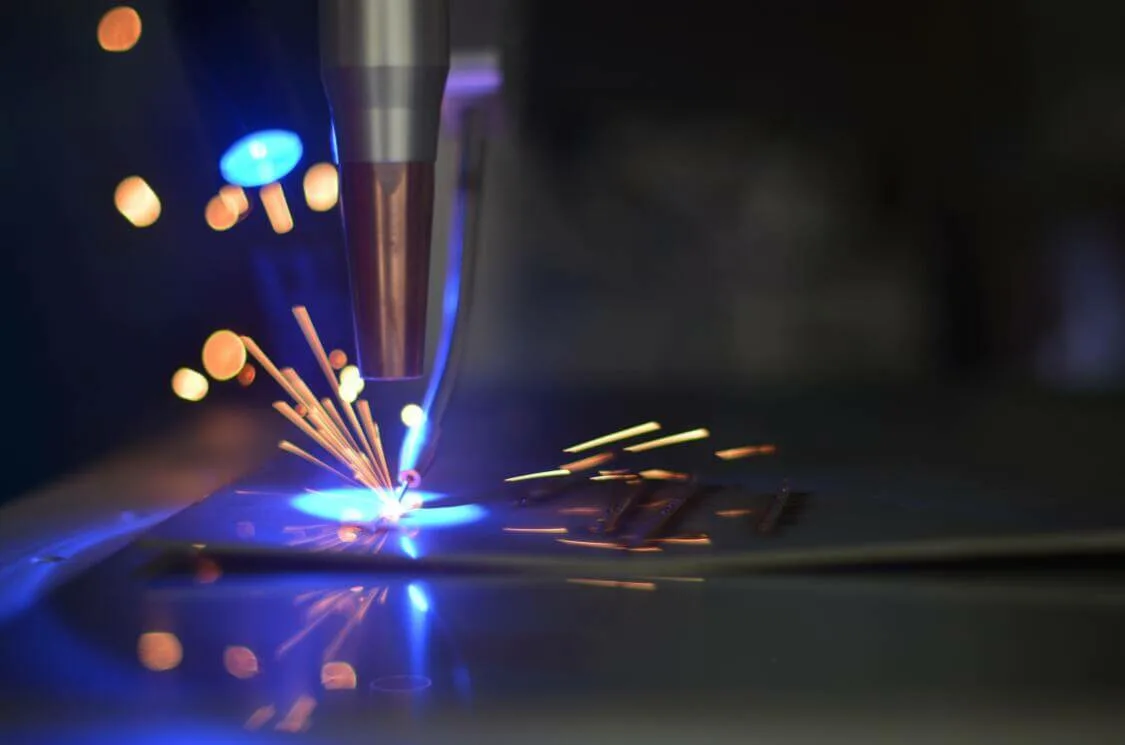

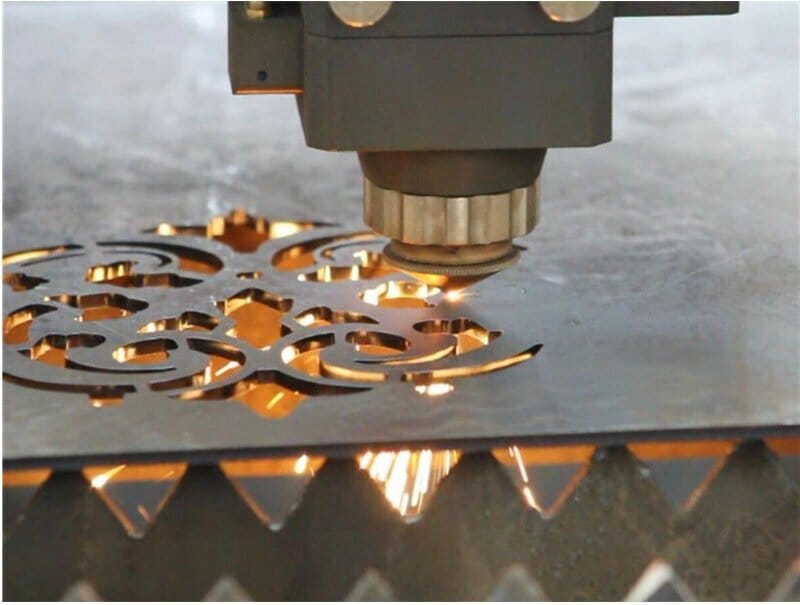

Laser cutting is a powerful and precise method for working with various materials, especially metals. One critical component in this process is the nozzle. Choosing the right nozzle can significantly impact the quality and efficiency of your cuts. Here’s a straightforward guide to help you make the best choice.

Understanding the Role of the Nozzle

The nozzle, also known as the copper nozzle, is a small but crucial part of the laser cutting head. It directs the laser beam and the assist gas onto the material you’re cutting. Its main functions include:

- Focusing the Assist Gas: It creates a high-pressure stream that blows away molten and vaporized material, leaving a clean cut.

- Protecting the Lens: It prevents debris from bouncing back and contaminating the laser’s internal components.

The Importance of Alignment

For optimal cutting results, the nozzle and the laser beam must be perfectly aligned. If they are not aligned, several problems can occur:

- Inaccurate Cuts: The laser may hit off-center, causing cuts that don’t match your expectations.

- Damage to the Nozzle: An off-center laser can strike the nozzle’s inner wall, potentially burning or damaging it.

How to Check Alignment:

- Stick a piece of transparent tape over the nozzle’s opening.

- Set the laser power to around 100W and pulse it to mark the tape.

- Remove the tape and see if the burn mark is centered. If not, adjust the laser head until the mark is in the middle.

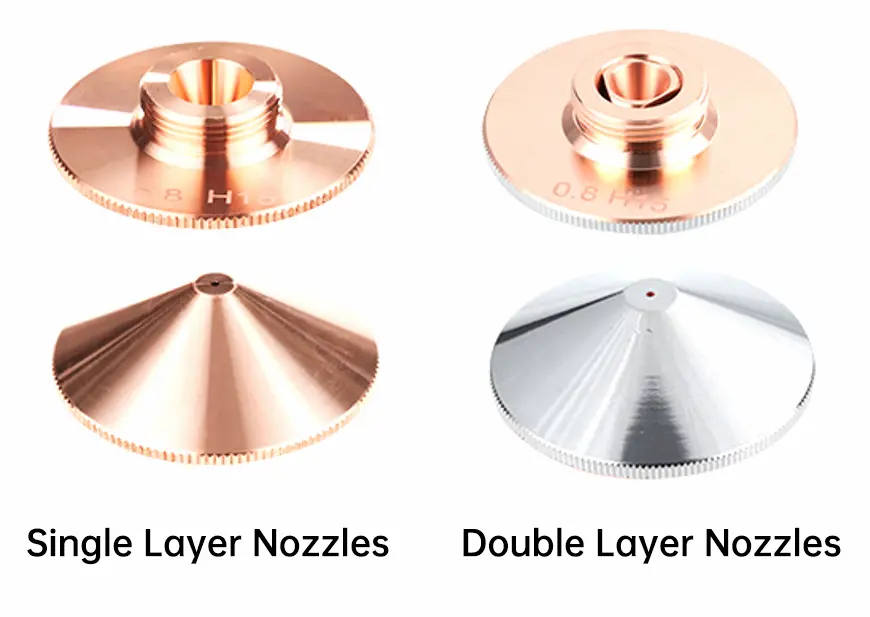

Types of Nozzles

Choosing the right nozzle also involves selecting the correct type:

- Single Layer Nozzles: These are ideal for cutting metals like stainless steel, aluminum, and copper. They typically use nitrogen as the assist gas.

- Double Layer Nozzles: Designed for high-speed cutting, these are often used for cutting carbon steel with oxygen as the assist gas. Note that oxygen can cause the cut edges to oxidize and turn black.

Selecting the Right Nozzle Size

The size of the nozzle’s opening affects the gas flow and, consequently, the cutting quality:

- Small Diameter: Good for thin materials and detailed work. It provides high precision but might struggle with thicker materials.

- Large Diameter: Better for thick materials as it allows more gas to flow through, but it can reduce precision and cause more spatter, potentially shortening the life of your lens.

Maintenance Tips

- Keep It Clean: Regularly clean the nozzle to remove any buildup of molten material.

- Handle with Care: Store nozzles properly to avoid deformation or damage.

Conclusão

Choosing the right nozzle for laser cutting isn’t just about picking one that fits; it’s about understanding your material, the type of cut you need, and maintaining proper alignment and cleanliness. By following these guidelines, you’ll achieve cleaner cuts and extend the life of your equipment. Happy cutting!