1. Introdução

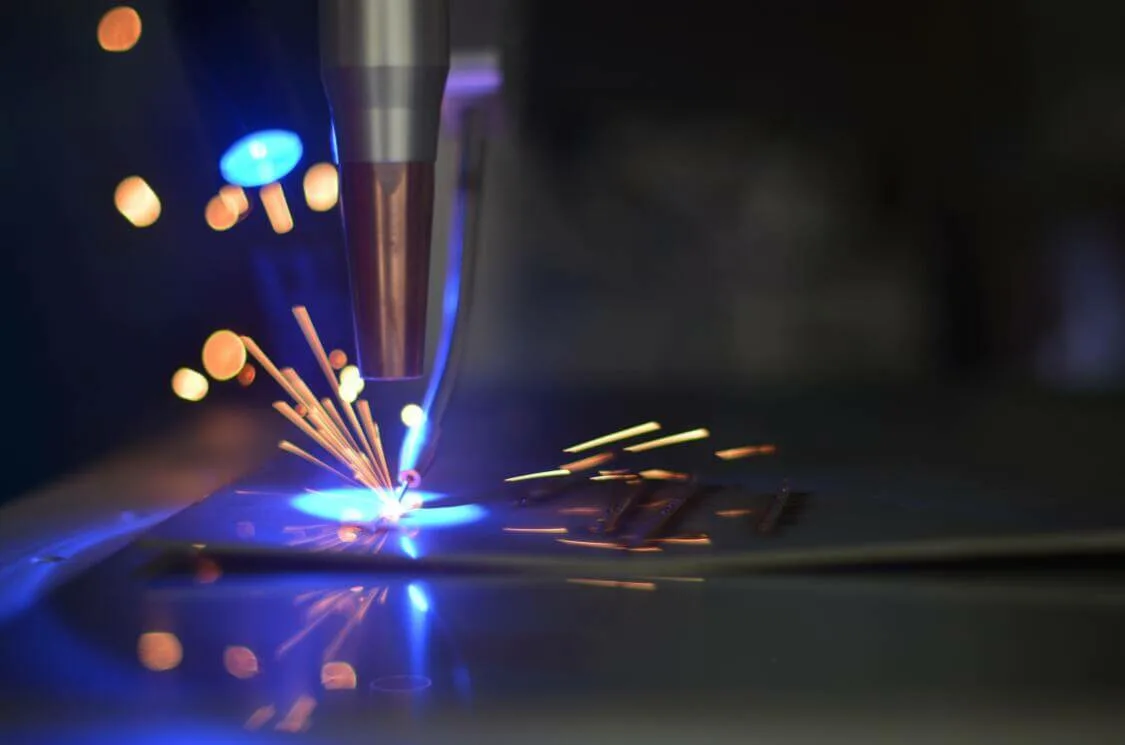

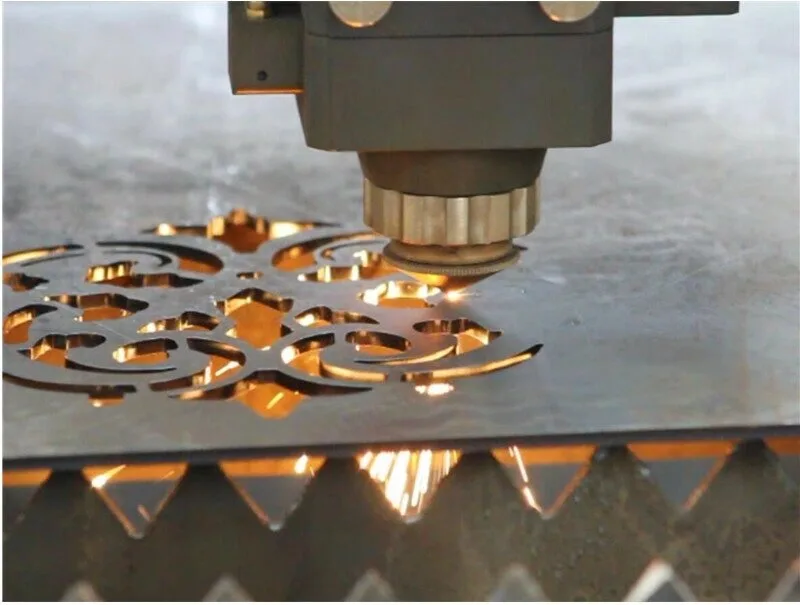

In the fast-paced world of manufacturing, every second counts. Laser cutting technology has revolutionized metal fabrication, offering precision and versatility that traditional cutting methods simply can’t match. However, as industry demands grow ever more demanding, manufacturers face a constant challenge: how to maximize efficiency without compromising quality. Enter jump cutting – a game-changing innovation that’s transforming the landscape of laser cutting operations.

Jump cutting, also known as “frog jump” technology, represents a significant leap forward in laser cutting efficiency. At its core, this technology addresses one of the most overlooked aspects of laser cutting operations: the time spent between cuts. While the actual cutting process might be lightning-fast, traditional laser cutting machines often waste precious seconds moving between cutting points, following rigid, inefficient paths that include separate lifting, moving, and lowering movements.

Think of a pizza delivery driver who must return to the restaurant after each delivery versus one who can optimize their route to handle multiple deliveries in a single trip. Jump cutting brings this same principle of intelligent path optimization to laser cutting, fundamentally changing how cutting heads move from point to point across a metal sheet.

2. Understanding Jump Cutting Technology

Function Description:

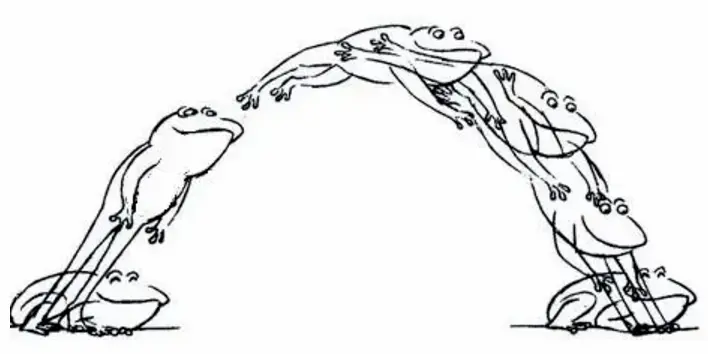

Jump cutting is a technique that allows the laser cutting head to optimize its movement path by reducing unnecessary vertical movements. This is achieved by enabling the cutting head to ascend and descend simultaneously while moving horizontally, much like a frog’s leap, hence the term “jump cutting.”

Technical Principles:

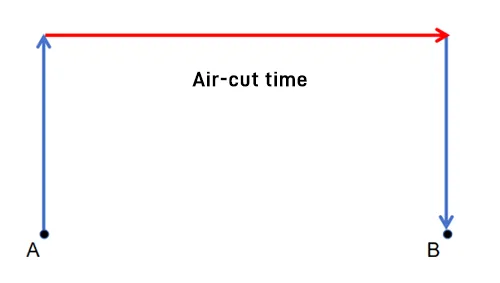

In traditional laser cutting, the cutting head must complete three sequential actions after each cut: ascend to a safe height, move horizontally to the next point, and then descend. This sequence results in considerable idle time, known as air-cut time. Jump cutting merges these movements into two steps—ascending and moving simultaneously—significantly reducing the overall air-cut time.

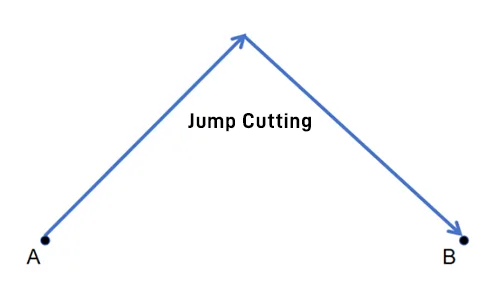

Visual Explanation of Path Optimization:

When processing a sheet of material with multiple cut points, the cutting head traditionally follows a step-by-step path. Jump cutting simplifies this by allowing the head to elevate while transitioning, effectively turning a series of movements into a more streamlined trajectory, resembling a parabolic arc.

3. Key Benefits of Jump Cutting

Time Savings and Efficiency Improvements:

Jump cutting drastically reduces the time spent on non-productive movements. For large-scale manufacturing, even saving a second per transition can lead to substantial time savings across thousands of cuts. For instance, if a manufacturer processes 6,000 sheets with multiple holes, the cumulative time saved can exceed 100 hours.

Production Cost Reduction:

With enhanced efficiency comes cost savings. Reducing idle time directly translates into lower operational costs, benefiting businesses by increasing their profit margins.

Impact on Large-Scale Manufacturing:

Jump cutting is particularly advantageous for large parts where the distances between cut points can be significant. By minimizing the time spent moving between cuts, manufacturers can meet tight production schedules more effectively.

Energy Efficiency Advantages:

Reducing the time machines are in operation not only saves on labor costs but also lowers energy consumption, aligning with sustainability goals.

4. Technical Implementation

Hardware Requirements:

To implement jump cutting effectively, laser cutting machines need high-performance components, including robust motion control systems capable of rapid transitions.

Software and Control Systems:

Advanced software that facilitates path optimization and real-time adjustments is essential for maximizing the benefits of jump cutting. Regular updates can help adapt to evolving production demands.

Integration with Existing Laser Cutting Machines:

Most modern laser cutting machines can be upgraded to support jump cutting functionalities. This often involves integrating new software and possibly upgrading certain hardware components.

Optimization Strategies:

Continuous analysis of cutting patterns and refinement of movement strategies can yield further improvements in efficiency. Utilizing advanced algorithms for path planning can help optimize the jump cutting process.

5. Conclusion

Jump cutting represents a significant advancement in laser cutting technology, offering numerous benefits, including improved efficiency, reduced costs, and enhanced energy use. As manufacturers adopt this innovative technique, they can boost their production capabilities and remain competitive in a rapidly evolving market. The ongoing evolution of jump cutting technology will likely lead to even greater efficiencies and capabilities in the future, further solidifying its role in modern manufacturing.

By embracing jump cutting, businesses can streamline their operations, reduce waste, and enhance overall productivity—key factors in thriving in today’s competitive landscape.