Modern üretimde 5 eksenli lazer kesimin önemi önemlidir. Çeşitli endüstrilerde yeniliğe, verimliliğe ve mükemmelliğe doğru bir hamleyi temsil eder. Bu makale, özellikleri, uygulamaları ve faydaları dahil olmak üzere 5 eksenli lazer kesimi araştırmaktadır. Bunu geleneksel 3D lazer kesim ile karşılaştıracağız ve maliyetini etkileyen faktörleri tartışacağız. Ek olarak, bu gelişmiş makinelerin karmaşık kesim ihtiyaçlarını nasıl karşıladığını, mühendislere, tasarımcılara ve üreticilere nasıl fayda sağladığını vurgulayacağız. Bu makalenin sonunda, mekaniğinden endüstri katkılarına kadar 5 eksenli lazer kesim hakkında kapsamlı bir anlayışa sahip olacaksınız.

5 Eksenli Lazer Kesim nedir?

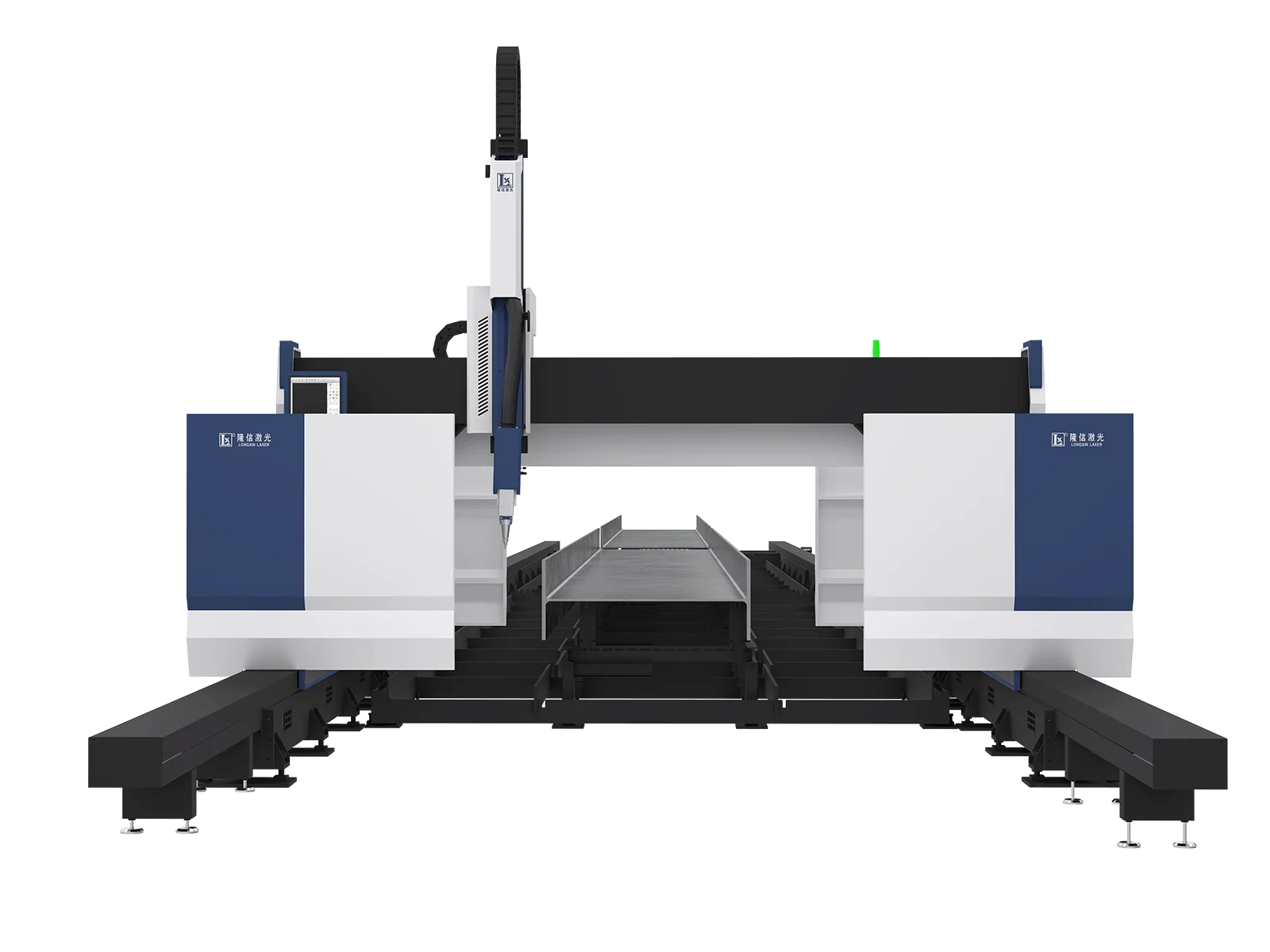

5 eksenli lazer kesim, geleneksel lazer kesim sistemlerinin yeteneklerini önemli ölçüde artıran gelişmiş bir CNC (bilgisayar sayısal kontrollü) üretim sürecidir. Bu teknoloji, lazer kafasının aynı anda beş farklı eksende hareket etmesini sağlayarak karmaşık şekilleri ve geometrileri yüksek hassasiyetle kesme yeteneği sağlar.

5 Eksenli Lazer Kesim Teknolojisine Genel Bakış

5 Eksenli lazer kesimin anahtarı, X, Y ve Z'nin standart üç doğrusal eksenine A ekseni ve B ekseni olarak bilinen iki dönme ekseninin eklenmesidir. Bu ek eksenler, kesme kafasının iş parçası etrafında manevra yaparken dönmesini ve eğilmesini sağlar, bu da kesme kafasının dönmesini ve eğilmesini sağlar. hemen hemen her açıdan kesim. Bu beş eksen boyunca hareket şunları içerir:

- X Ekseni: Sola ve sağa yatay hareket

- Y Ekseni: Ön ve arka yatay hareket

- Z Ekseni: Yukarı ve aşağı dikey hareket

- A Ekseni: X ekseni etrafında dönme

- B Ekseni: Y ekseni etrafında dönme

Bu yetenek sadece daha karmaşık tasarımların kesilmesini kolaylaştırmakla kalmaz, aynı zamanda çoklu kurulum ihtiyacını da önemli ölçüde azaltır, böylece üretim verimliliğini artırır ve hata olasılığını azaltır.

3 Eksenli ve 4 eksenli Lazer Kesicilerle Karşılaştırma

Kesme tablasını eğme veya döndürme yeteneği olmadan yalnızca X, Y ve Z eksenlerinde çalışan 3 eksenli lazer kesicilerle karşılaştırıldığında, 5 eksenli lazer kesim esneklik ve hassasiyette önemli bir gelişme sunar. 3 eksenli makineler tipik olarak iş parçasının farklı kesme açıları için manuel olarak yeniden konumlandırılmasını gerektirir, bu da zaman alıcı ve hizalama hatalarına eğilimli olabilir.

Öte yandan, 4 eksenli lazer kesim sınırlı dönme hareketi ekler, ancak 5 eksenli makinelerle aynı düzeyde çok yönlülük sağlamaz. 4 Eksenli teknoloji bazı açılı kesimlere izin verirken, yine de daha karmaşık geometriler için ek kurulumlar gerektirir.

5 eksenli lazer kesim makineleri, kesme kafasının parçaya tek bir kurulumda her yönden yaklaşmasını sağlayarak bu sınırlamaların üstesinden gelir. Bu sadece daha fazla hassasiyet sağlamakla kalmaz, aynı zamanda daha az eksenle elde edilmesi zor veya imkansız olan karmaşık parçaların oluşturulmasına da olanak tanır. Ayrıca, iş parçasını yeniden konumlandırmaya gerek kalmadan birden fazla açıdan delik delme yeteneği, 5 eksenli lazer kesimi, havacılık ve tıbbi cihaz üretimi gibi yüksek hassasiyet ve verimlilik gerektiren endüstrilerde özellikle değerli kılar.

Özetle, 5 eksenli lazer kesim, geleneksel 3 eksenli ve 4 eksenli yöntemlere göre önemli bir ilerlemeyi temsil eder ve karmaşık üç boyutlu parçaların yüksek hassasiyet ve verimlilikle kesilmesinde gelişmiş yetenekler sunar.

Modern Üretimde 5 Eksenli Lazer Kesimin Etkisi

Gelişen üretim ve tasarım ortamında, kesme tekniklerinde hassasiyet ve esneklik her şeyden önemlidir. Bu teknolojik gelişmelerin ön saflarında yer almaktadır 5 eksenli lazer kesim, malzemelerin nasıl şekillendirildiği ve rafine edilmesinde devrim yaratan bir yöntem.

Eşsiz Doğruluk ve Karmaşıklık:

- Geleneksel 3D kesim yeteneklerinin ötesine geçer.

- Karmaşık geometrilerin işlenmesinde üstün doğruluk sunar.

Geniş Uygulamalar:

- Kritik bileşen üretimi için havacılıkta kullanılır.

- Karmaşık mücevher tasarımları yaratmada esastır.

Önemli Gelişmeler:

- Yeniliğe ve verimliliğe doğru bir sıçramayı temsil eder.

- Üretim olanaklarının sınırlarını zorlamada çok önemlidir.

5 Eksenli Lazer Kesim Neden Önemlidir?:

- Hassasiyet: Kesin spesifikasyonlar gerektiren endüstriler için çok önemli olan diğer birçok kesme yönteminden daha yüksek hassasiyet seviyelerine ulaşır.

- Esneklik: Çeşitli malzemelere ve karmaşık şekillere uyarlanabilir, tasarım olanaklarını artırır.

- Verimlilik: Üretim süreçlerini düzene sokar, atıkları azaltır ve genel üretim verimliliğini artırır.

5 Eksenli Lazer Kesim Makinelerinin Temel Özellikleri

5 eksenli lazer kesim makineleri kesme uygulamalarında hassasiyeti, verimliliği ve çok yönlülüğü artıran bir dizi özellik sunarak üretim teknolojisinde önemli bir sıçramayı temsil eder. Bu makineler, özellikle çeşitli endüstrilerdeki karmaşık üretim ihtiyaçlarını karşılayan gelişmiş yetenekleri ve ayrıntılı özellikleri ile ünlüdür.

5 Eksenli makinelerin ayrıntılı özellikleri

5 Eksenli lazer kesim makineleri, yüksek hassasiyet ve operasyonel verimlilik sağlayan sağlam bir dizi spesifikasyonla donatılmıştır. Temel özellikler arasında 3300W güç çıkışlı bir lazer osilatör, 8GB sabit disk kapasitesi ve 300 mm'de ±0,03 mm'lik gelişmiş konumlandırma doğruluğu bulunur. Bu makinelerde ayrıca bir kesme koşulları kitaplığı ve “Üstün Kesim " olarak bilinen yüksek basınçlı bir gaz destek sistemi bulunur."Yapısal tasarım, sayısallaştırma için 5 eksenli bir kumanda kolu ve makinenin kullanılabilirliğini ve hassasiyetini artıran CMM tipi bir öğretim probu içeriyor.

Operasyonel yetenekler, bilyalı vidalar kullanan bir tahrik mekanizması ve doğrusal bilyalı kılavuzlara sahip bir kılavuz mekanizma ile daha da desteklenerek düzgün ve doğru hareket sağlanır. Makinenin hızlı besleme hızları, X ve Y eksenlerinde dakikada 40.000 mm'ye ve Z ekseninde dakikada 30.000 mm'ye ulaşır, kesme besleme hızları da yüksek hızları korur, üretkenliği artırır ve çevrim sürelerini kısaltır.

Gelişmiş kesme yetenekleri

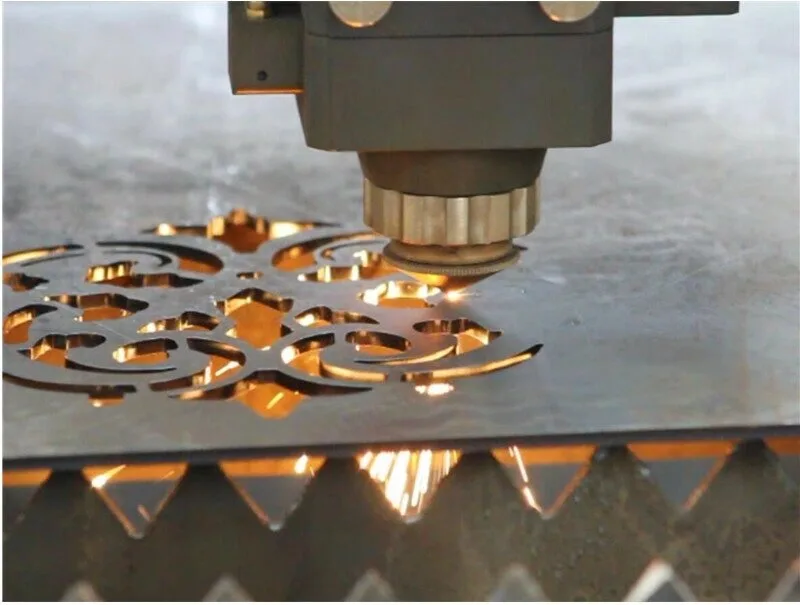

5 eksenli lazer kesim makineleri, karmaşık geometrileri yüksek hassasiyetle üretme yeteneklerinde üstündür. Bu makineler lazeri beş farklı eksen boyunca manipüle edebilir-X, Y, Z ve iki dönme ekseni (A ekseni ve B ekseni). Bu çok eksenli özellik, geleneksel 3 eksenli sistemlerle elde edilmesi zor olan karmaşık kesme açılarına ve karmaşık parça geometrilerine olanak tanır. Ek eksenler, makinenin iş parçasına hemen hemen her açıdan yaklaşmasını sağlayarak birden fazla kurulum ihtiyacını azaltır ve kullanım hatalarını en aza indirir.

Teknoloji, metaller, plastikler ve kompozitler dahil olmak üzere çok çeşitli malzemelerin kesilmesini destekleyerek havacılık, otomotiv ve tıbbi cihazlar gibi endüstriler için uygun hale getirir. Üretim süreçlerinde esneklik gerektiren işletmeler için minimum kesinti süresiyle malzemeler arasında geçiş yapma yeteneği çok önemlidir.

Ayrıca, 5 eksenli makineler, operasyonların gece veya hafta sonu insan müdahalesi olmadan devam edebileceği, ışıksız üretime izin vererek verimliliği artırır. Bu yetenek yalnızca iş hacmini artırmakla kalmaz, aynı zamanda işçilik maliyetlerini de düşürerek üreticilerin pazarda rekabet üstünlüğünü korumasını sağlar.

Özetle, 5 eksenli lazer kesim makineleri, kesme işlemlerinin hassasiyetini, verimliliğini ve çok yönlülüğünü önemli ölçüde artıran ileri teknolojik özelliklerle donatılmıştır. Bu makineler, karmaşık geometrilerin ve yüksek doğruluğun çok önemli olduğu endüstrilerde çok önemlidir ve üretim hızı, maliyet etkinliği ve malzeme taşıma açısından önemli faydalar sağlar.

Uygulamalar ve Endüstriler

Otomotiv

5 eksenli lazer kesim, üretim süreçlerinin hassasiyetini ve verimliliğini artırarak otomotiv endüstrisinde devrim yaratıyor. Bu teknoloji özellikle şasi, süspansiyon sistemleri, kapı panelleri ve motor bileşenleri gibi karmaşık parçaların kesilmesi ve şekillendirilmesinde etkilidir. Metaller ve kompozitler de dahil olmak üzere çok çeşitli malzemeleri işleme yeteneği, hafif ancak dayanıklı parçaların üretilmesine olanak tanır. Ek olarak, termoform teknolojisinin 5 eksenli lazer kesim ile entegrasyonu, otomotiv tasarımı ve üretiminde önemli bir ilerlemeyi yansıtan üst düzey ve enerji tasarruflu araçların üretiminde yeni standartlar belirliyor.

Havacılık

Havacılık sektöründe, hafif özellikleri yüksek mukavemetle birleştiren bileşenlere olan talep kritik öneme sahiptir. 5 eksenli lazer kesim, türbin kanatları ve yapısal bileşenler gibi parçaların imalatında kullanılan titanyum ve İnconel alaşımları gibi gelişmiş malzemelerin hassas kesimini kolaylaştırarak bu gereksinimleri karşılar. Teknolojinin kesme işlemi sırasında malzeme bütünlüğünü koruma yeteneği, havacılık bileşenlerinin performansını ve güvenliğini sağlamak için hayati öneme sahiptir. 5 Eksenli lazer kesimin sağladığı hassasiyet ve çok yönlülük, onu havacılık endüstrisinde vazgeçilmez bir araç haline getirerek hem üretim hızını hem de maliyet verimliliğini önemli ölçüde artırdı.

Tıbbi

Medikal endüstrisi, özellikle karmaşık tıbbi cihazların ve implantların üretiminde, 5 eksenli lazer kesimin yüksek hassasiyetinden ve tekrarlanabilirliğinden büyük ölçüde yararlanır. Bu teknoloji, hasta güvenliğini ve cihaz işlevselliğini sağlamak için azami doğruluğun gerekli olduğu stentler ve ortopedik implantlar gibi ürünlerin üretimi için çok önemlidir. Çeşitli malzemelerle çalışma yeteneği ve karmaşık tasarımların kesilmesindeki hassasiyet, 5 eksenli lazer kesimin tıbbi cihaz üretiminde tercih edilen bir teknoloji olmasının nedeni olup, daha etkili ve yenilikçi tıbbi tedavilerin geliştirilmesine yardımcı olmaktadır.

Mücevher

Kuyumculuk endüstrisinde 5 eksenli lazer kesim, geleneksel işçiliği teknikleriyle elde edilmesi zor veya imkansız olan karmaşık tasarımların oluşturulmasına olanak tanır. Bu teknolojinin hassasiyeti, kuyumcuların değerli metallerdeki ayrıntılı desenleri ve karmaşık şekilleri keserek mücevher parçalarının sanatını ve benzersizliğini artırmasını sağlar. Lazer kesim kullanımı, özel tasarımlar ve kişiselleştirme için gerekli olan dayanıklı ve hassas sonuçlar sağlayarak gravür ve işaretlemeye kadar uzanır.

Öğrenme ve Gelişim

5 eksenli lazer kesim, özellikle prototipleme ve deneysel tasarımlar gerektiren sektörlerde, eğitim ve mesleki gelişim ortamlarında da çok önemli bir rol oynar. Bu teknoloji, karmaşık modellerin ve parçaların hızlı bir şekilde oluşturulmasını destekleyerek uygulamalı öğrenmeyi ve yeniliği kolaylaştırır. Ar-Ge ortamlarında, 5 eksenli lazer kesim, geliştirme sürecini hızlandırarak, teknolojiyi ve öğrenme uygulamalarını ilerletmek için gerekli olan hızlı yinelemelere ve iyileştirmelere olanak tanır.

5 Eksenli Lazer Kesimin Faydaları

3D Lazer Kesim

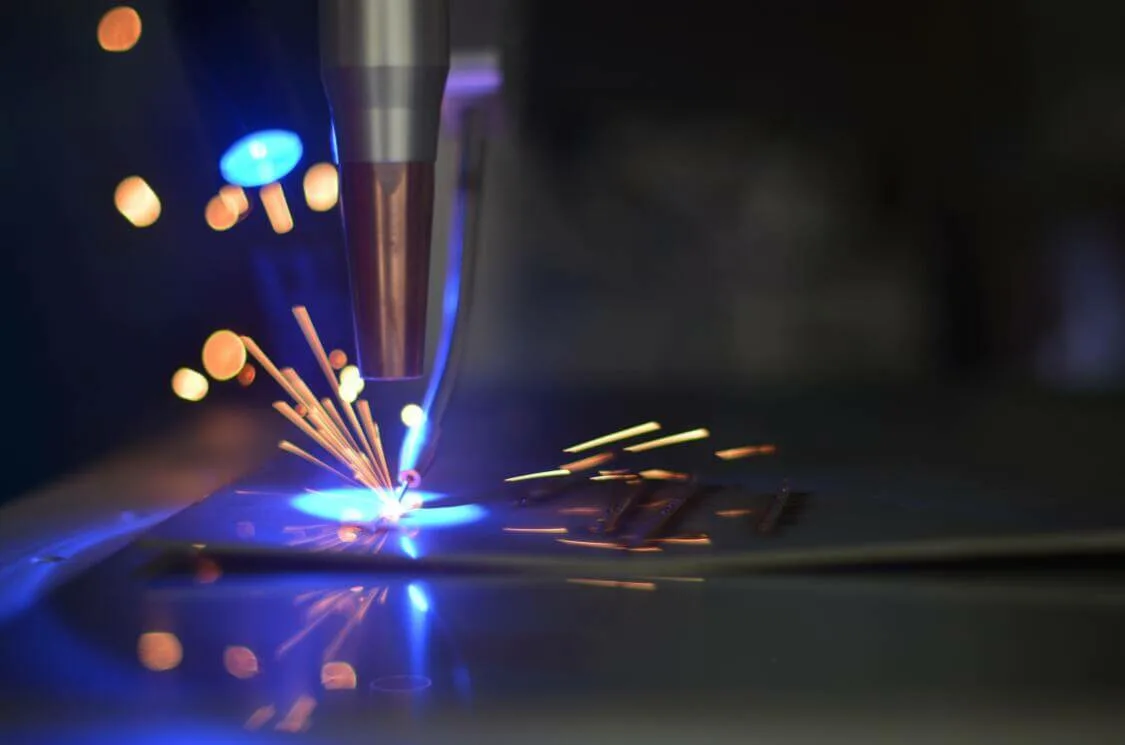

5 eksenli lazer kesim makineleri, karmaşık şekilleri ve konturları benzersiz bir hassasiyetle işleme yeteneğinde önemli bir ilerleme sağlar. Bu teknoloji, geleneksel 2B kesme yöntemleriyle zor veya imkansız olabilecek açısal delikler ve karmaşık geometriler gibi karmaşık kesimlere olanak tanır. CAD yazılımının entegrasyonu, lazeri insan saçı genişliğinin yaklaşık dörtte biri olan yaklaşık 25 mikrona kadar hassas kesimler yapması için yönlendirerek süreci daha da geliştirir.

Geliştirilmiş Kesme Hassasiyeti ve Hassasiyeti

5 Eksenli lazer kesimin hassasiyeti, özellikle geleneksel kesme yöntemlerine kıyasla büyük bir avantajdır. Bu makineler, yaklaşık ±0.0005 inçlik bir kesme doğruluğu elde ederek, her parçanın minimum varyasyonla tam olarak spesifikasyona göre kesilmesini sağlar. İş parçasını birden çok kez yeniden konumlandırmaya gerek kalmadan hemen hemen her açıdan kesme yeteneği, hata olasılığını azaltır, böylece malzemenin bütünlüğünü ve kalitesini korur.

Artan Verimlilik ve Düşük Maliyetler

5 eksenli lazer kesim, daha hızlı ve daha verimli kesim işlemleri sağlayarak verimliliği artırır. Teknoloji, yalnızca üretimi hızlandırmakla kalmayıp aynı zamanda işçilik maliyetlerini de azaltan çoklu kesimler için tek bir kurulum sağlar. Üreticiler, ikincil operasyonlara ve çoklu kurulumlara olan ihtiyacı en aza indirerek daha hızlı geri dönüş süreleri ve daha düşük üretim maliyetleri elde edebilirler. Ek olarak, bu makinelerin minimum insan müdahalesi ile çalışabilme kabiliyeti, ışıksız üretimi destekleyerek iş hacmini daha da artırır ve işletme maliyetlerini düşürür.

Bu avantajlar, hassasiyetin, verimliliğin ve maliyet etkinliğinin en önemli olduğu otomotivden havacılığa kadar çeşitli endüstrilerde 5 eksenli lazer kesim teknolojisinin dönüştürücü etkisinin altını çiziyor.

Sonuç

5 eksenli lazer kesim, geleneksel 3D kesim yöntemlerine göre üstün hassasiyet ve verimlilik sunan, üretimde büyük bir teknolojik ilerlemeyi temsil eder. Bu teknoloji, havacılık, otomotiv, tıbbi cihazlar ve mücevher tasarımı gibi endüstriler için gerekli kılan, eşsiz doğrulukta karmaşık geometrilerin oluşturulmasına olanak tanır. 5 eksenli lazer kesim, çoklu kurulum ihtiyacını azaltarak ve hataları en aza indirerek üretkenliği artırır ve maliyetleri düşürür. Araştırma ve geliştirme devam ettikçe, bu teknolojinin üretim süreçlerinde devrim yaratma potansiyeli artarak verimlilik, malzeme taşıma ve tasarım karmaşıklığında önemli gelişmeler vaat ediyor.