Introduction

In the automotive industry, precision and efficiency are paramount, especially for components like shock absorbers. Our client, a leading shock absorber manufacturer in Indonesia, faced significant challenges in processing round pipes. This case study explores how the LX-GLX70 laser tube cutting machine transformed their production line, enhancing both efficiency and product quality.

Company Background

Located in Indonesia, our client is a major manufacturer of automotive shock absorbers, supplying high-quality components to various vehicle manufacturers. Their production process involves cutting round pipes, a critical component in shock absorber assembly.

Challenges Faced

Prior to adopting the LX-GLX70 laser tube cutting machine, the company encountered several obstacles:

- Inefficient Processes: Traditional cutting methods were slow and labor-intensive.

- Inconsistent Cuts: Variability in cut quality led to material wastage and rework.

- High Costs: Manual processes and high waste levels drove up operational costs.

These issues limited their production capacity and affected their ability to meet growing demand.

Solution Implemented

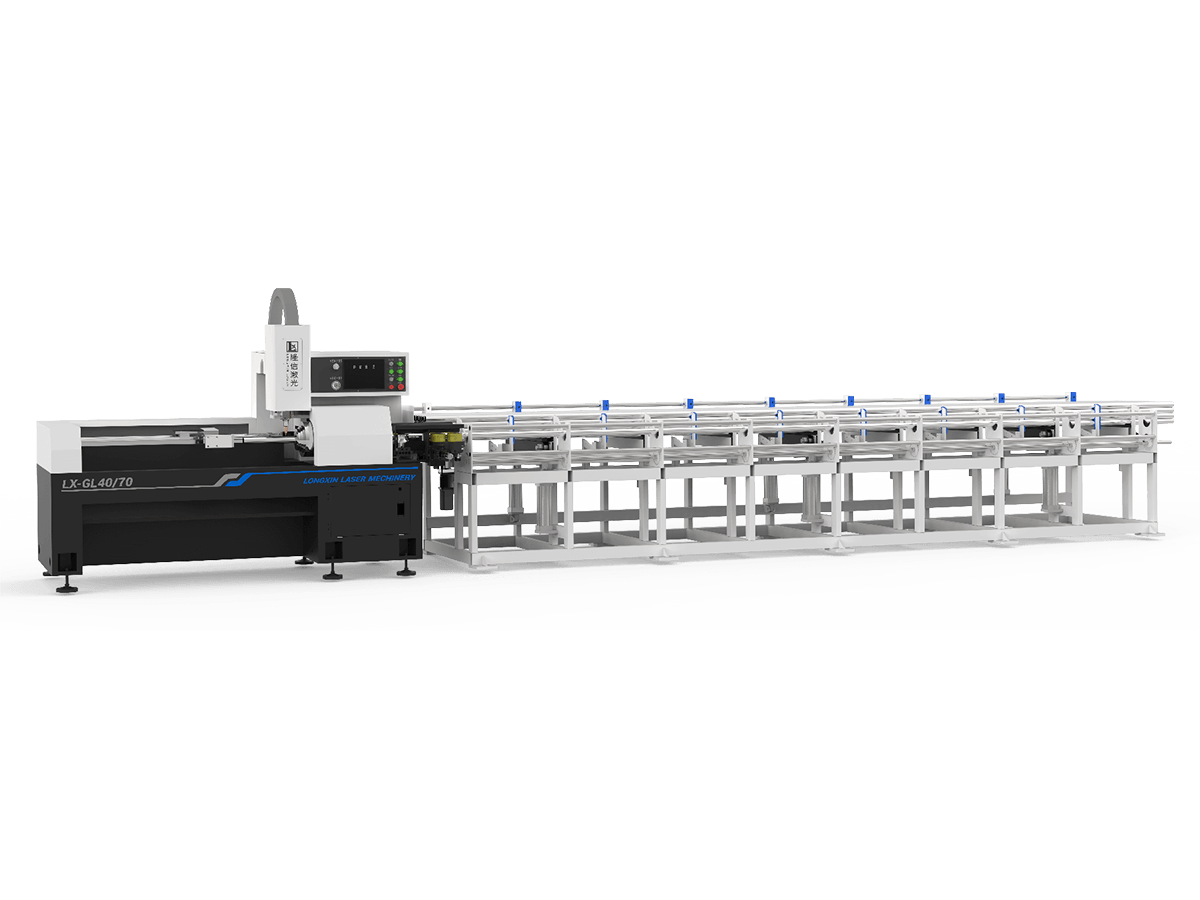

To address these challenges, the company implemented the LX-GLX70 laser tube cutting machine. This advanced equipment provided several key benefits:

- Precision Cutting: The LX-GLX70 delivers highly accurate cuts, reducing material wastage and improving overall product quality.

- Enhanced Efficiency: Automated cutting significantly increased production speed and reduced reliance on manual labor.

- Versatility: The machine’s ability to handle various pipe sizes and materials provided greater flexibility in production.

Implementation Process

The transition to using the LX-GLX70 was smooth and efficient:

- Setup: The installation team quickly set up the LX-GLX70 at the client’s facility with minimal disruption.

- Training: Comprehensive training sessions ensured that the client’s staff could operate the machine effectively.

- Optimization: The production process was refined to maximize the benefits of the LX-GLX70, seamlessly integrating it into the existing workflow.

Results Achieved

The introduction of the LX-GLX70 brought about significant improvements:

- Increased Output: Production speed rose by 40%, enabling the company to fulfill larger orders.

- Cost Reduction: Operational costs dropped by 30% due to decreased labor needs and reduced material waste.

- Superior Quality: Consistent, high-quality cuts enhanced the reliability and performance of the shock absorbers.

Customer Testimonial

The client has been extremely pleased with the performance of the LX-GLX70. Their feedback highlights the machine’s impact on their operations:

“The LX-GLX70 has revolutionized our manufacturing process. Its precision and speed have not only helped us meet our production targets but also significantly reduced our costs. The support from Longxin Laser has been exceptional, ensuring we get the most out of this advanced technology.”

Conclusion

The LX-GLX70 laser tube cutting machine has proven to be a game-changer for our Indonesian client, addressing their production challenges and delivering remarkable results. If you’re looking to upgrade your manufacturing capabilities and boost efficiency, contact us today to discover how the LX-GLX70 can transform your operations.

Ready to elevate your production process? Contact us to learn more about the LX-GLX70 laser tube cutting machine and arrange a demonstration.