Company Profile

- Customer: EMBRACE

- Industrie: Furniture

- Location: Malaysia

Challenge

EMBRACE, a leading furniture manufacturer in Malaysia, needed to enhance their production capabilities for metal components. They sought a solution that could efficiently cut thick carbon steel sheets while maintaining precision and reducing operational costs.

Solution

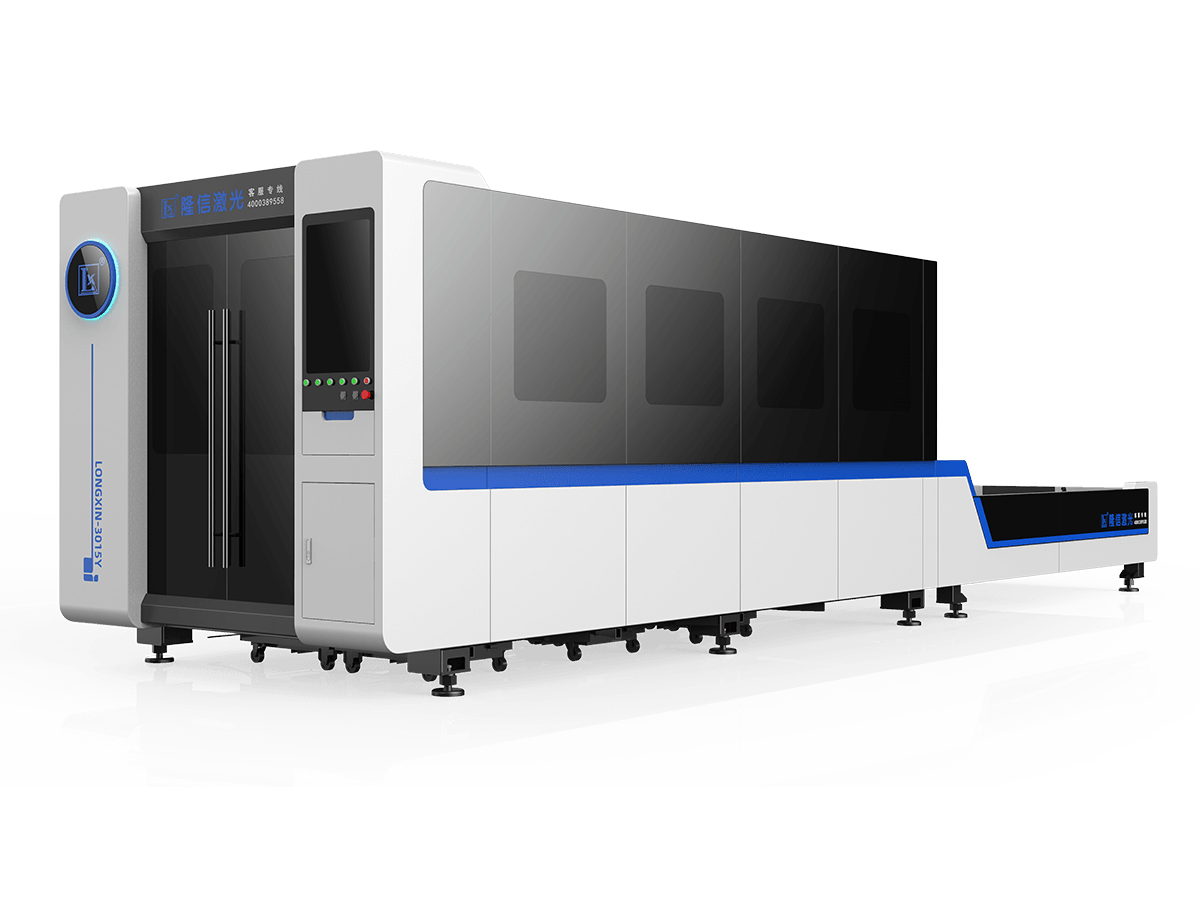

We recommended the LX-3015Y Metal Sheet Laser Cutting Machine to meet EMBRACE’s specific requirements.

Key Features of LX-3015Y:

- High-Precision Cutting:

- Capable of processing carbon steel sheets up to 9mm thick with high accuracy.

- XY motion accuracy of ±0.05mm/m ensures precise cuts for complex furniture designs.

- Cost-Effective Operation:

- Compact design fits in standard containers, significantly reducing overseas transportation costs.

- Cast aluminum beam, half the weight of traditional cast iron beams, enables faster operations and energy savings.

- Durability and Stability:

- Stress-relieved frame treated at 600°C ensures stability and prevents deformation, promising reliable operation for up to 20 years.

- Heavy-duty machine bed reduces vibration during high-speed cutting operations.

- Advanced Ventilation System:

- Patented zoned ventilation system with time-sharing and segmented dust extraction.

- Ensures a smoke-free cutting area, improving workplace safety and air quality.

Implementation

The LX-3015Y was installed at EMBRACE’s facility in Malaysia, with our team providing comprehensive training to maximize the machine’s potential.

Results

Since implementing the LX-3015Y, EMBRACE has experienced:

- Increased production speed and efficiency in metal component manufacturing.

- Improved precision in cutting 9mm carbon steel sheets, enhancing product quality.

- Reduced material waste and lower operational costs.

- Enhanced workplace safety due to the advanced ventilation system.

- Greater flexibility in furniture design options, allowing for more creative and complex metal elements.