Customer Profile

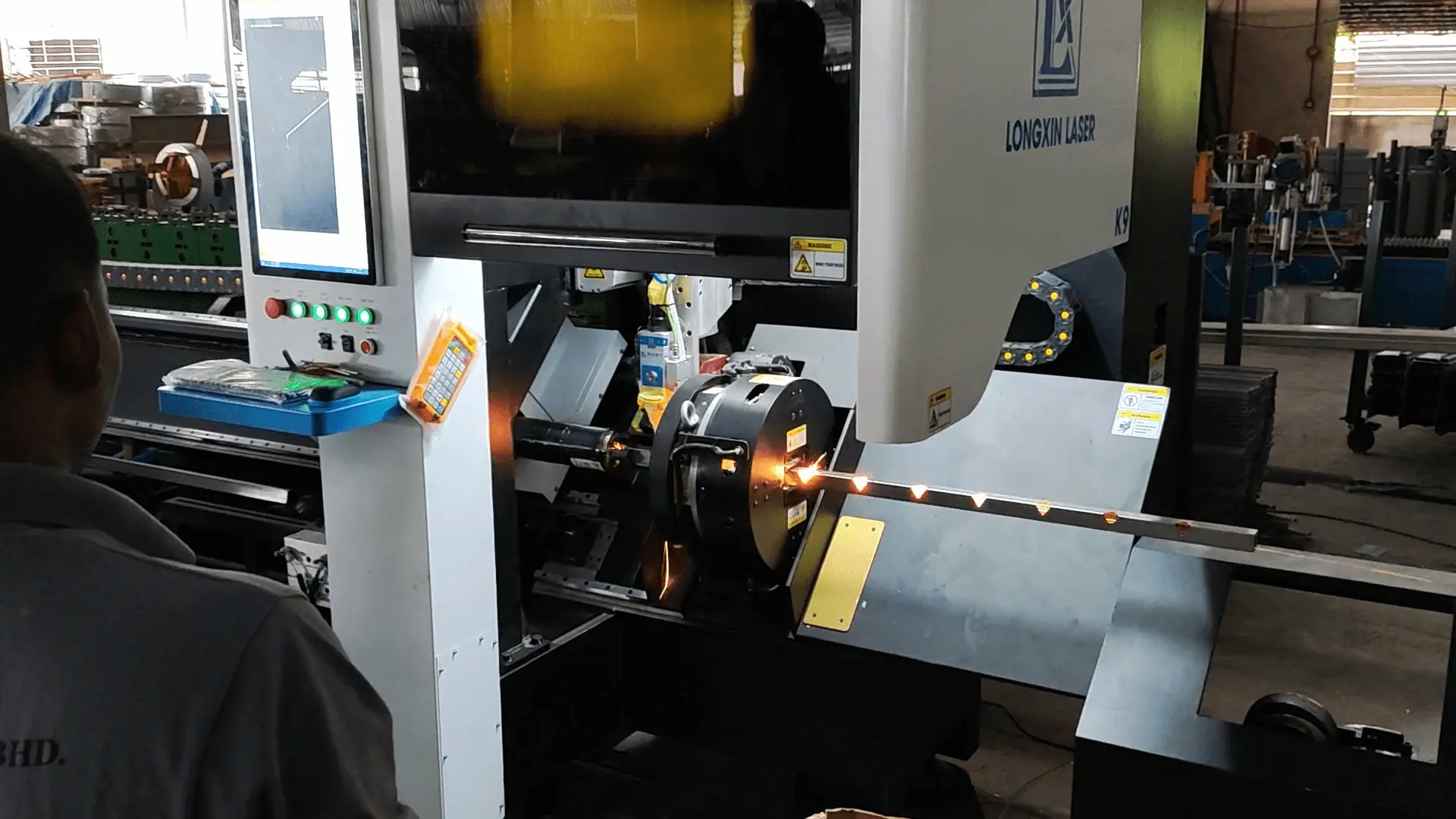

A Malaysian manufacturer specializing in the production of high-quality door and window frames has integrated the LX-K9 Ultra High-speed Small Pipe Laser Cutting Machine into their production line, achieving noteworthy improvements in efficiency and precision.

Manufacturing Requirements

The customer’s primary focus is the production of door and window frames using square tubes and T-shaped tubes with specific dimensions of 1919mm and 3232mm. These precise requirements demanded a cutting solution that could deliver both accuracy and high productivity while maintaining consistent quality across various tube profiles.

Solution Implementation:

Cutting diameter range compatibility:

Cutting Diameter Of Round Tube: ∅8-90mm

Cutting Diameter Of Square Tube: □8*8-80*80mm

Laser power range: 1500-3000W

Ultra-short tail design for material optimization

Impressive 1.5G acceleration for enhanced productivity

Advanced FSCUT system with optional nesting software

Key Advantages for the Customer’s Application

Perfect Size Range Match

The LX-K9’s cutting range (88-8080mm for square tubes) perfectly accommodates the customer’s required dimensions of 1919mm and 3232mm, ensuring optimal cutting performance for their specific tube sizes.

Enhanced Productivity

The machine’s 1.5G acceleration capability significantly improves production efficiency, allowing for faster processing of door and window frame components. The ultra-short tail design minimizes material waste, contributing to cost savings and environmental sustainability.

Precision Control

The implementation of the FSCUT system provides precise control over the cutting process, ensuring consistent quality across all manufactured components. The optional nesting software further optimizes material usage and production planning.