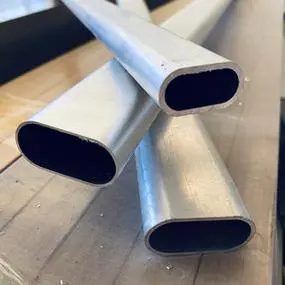

What is Oval Tubes?

Oval tube is a type of pipe with an elliptical cross-section. Compared to circular pipes, oval tubes offer several advantages:

- Space-saving design

- Easier installation

- Enhanced fluid delivery efficiency

Oval tubes are also known as flat round tubes or duck egg tubes, names that reflect their unique cross-sectional shape.

Classifications of Oval Tubes:

Flat oval tubes:

Symmetrical cross-section along the tube length, with parallel ends. These offer greater structural stability and are suitable for high-pressure or high-bending force applications.

Pointed oval tubes:

Cross-section forms a pointed shape at both ends, with a longer long axis compared to the short axis in the middle. These are used in specific designs for unique mechanical properties and space benefits.

Materials:

Oval tubes can be manufactured from various materials, including:

- Kohlenstoffstahl

- Edelstahl

- Aluminium

- Plastic

The choice of material depends on the specific application requirements, considering factors like pressure capacity, corrosion resistance, weight, and cost.

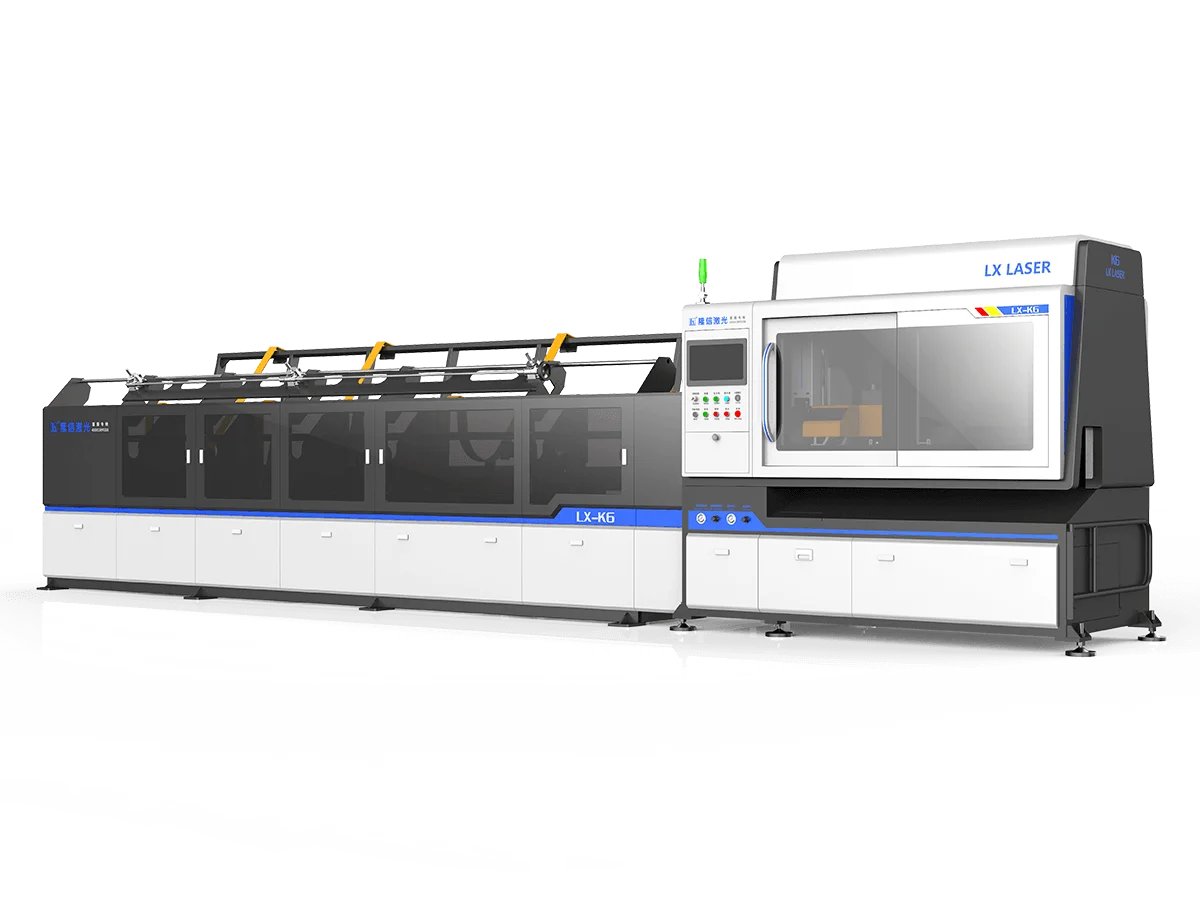

Oval Tube Laser Cutting Machine

An oval tube laser cutting machine is a specialized piece of equipment designed to cut, shape, and process oval tubes using high-powered laser technology. These machines offer precise cutting capabilities for various oval tube materials and sizes.

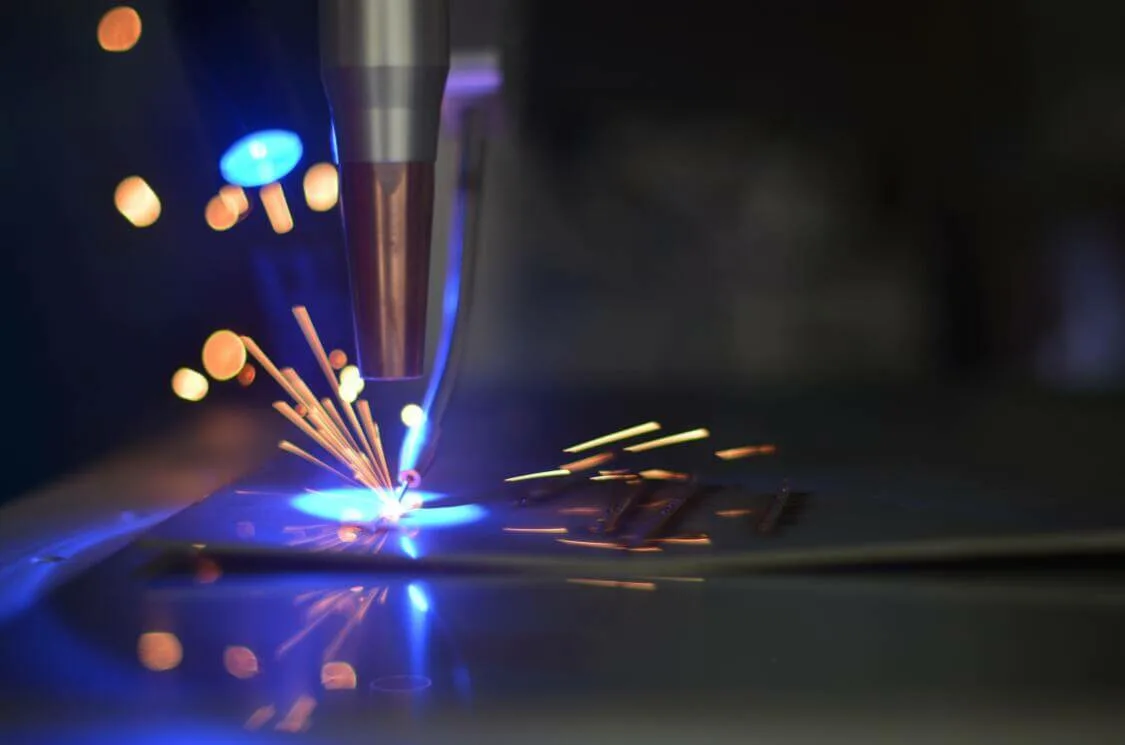

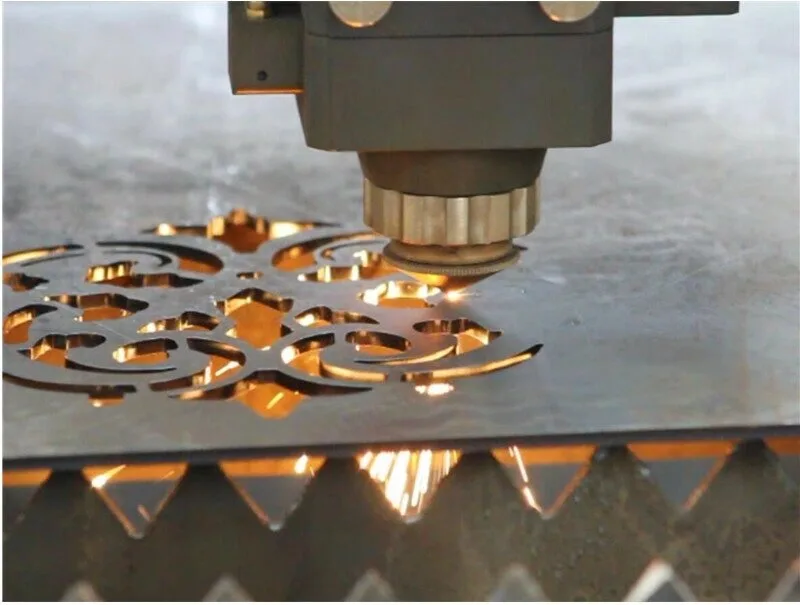

Oval Tube Laser Cutting Machine Cutting Effect Display

What is the Use of Oval Tubes?

Oval tubes are used in a wide range of applications due to their unique shape and properties. They are commonly used in construction, automotive, aerospace, and fluid transportation industries. The shape allows for more efficient space usage and can provide enhanced mechanical properties in structural applications.

Why Use an Oval Tube Laser Cutting Machine?

Using a laser cutting machine for oval tubes provides several benefits:

- Präzision: High accuracy in cutting, resulting in minimal material waste and precise fits.

- Geschwindigkeit: Faster processing compared to traditional cutting methods.

- Vielseitigkeit: Capable of cutting various shapes and sizes, including complex geometries.

- Automatisierung: Reduces the need for manual labor and increases production efficiency.

- Quality: Produces clean cuts with smooth edges, reducing the need for additional finishing.

How to Use a Laser Tube Cutting Machine for Oval Tubes

- Material Selection: Choose the appropriate oval tube material and size for your project.

- Machine Setup: Ensure the laser cutting machine is properly calibrated and set up for the specific oval tube material and thickness.

- Design Preparation: Create or import the cutting design into the machine’s software. Ensure the design accounts for the oval shape of the tube.

- Loading: Carefully load the oval tube into the machine’s material handling system. Many machines have specialized grips or chucks designed for oval tubes.

- Cutting Process: Initiate the cutting process. The machine will rotate the tube as needed to complete the cuts according to the design.

- Quality Check: After cutting, inspect the finished pieces for accuracy and quality.

- Post-processing: If necessary, perform any required post-processing steps, such as deburring or cleaning.

How to choose a oval tube laser cutting machine?

- The maximum tube dimensions you need to process

- The range of materials you’ll be cutting

- The required cutting speed and precision

- The machine’s power and capabilities

- Automation features for loading and unloading

- Software compatibility and ease of use

If you are a novice, please kontaktiere uns and we will have experts to provide you with the best solution

By carefully evaluating these factors, you can choose an oval tube laser cutting machine that best suits your production needs, budget, and long-term business goals. Remember to consult with machine manufacturers and industry experts to ensure you make an informed decision based on your specific requirements.