Customer Profile

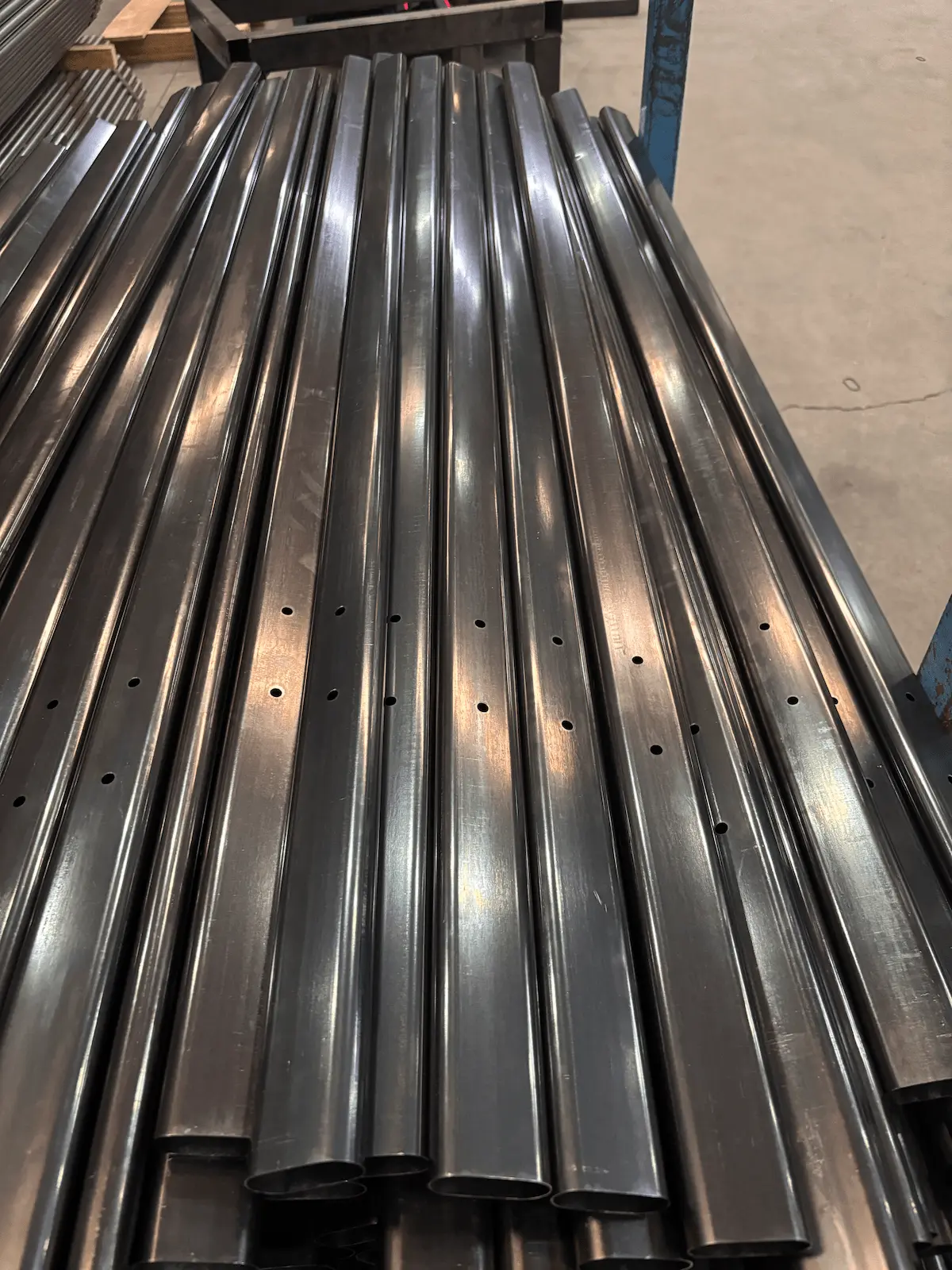

Cakmak, a professional ladder manufacturer based in Kayseri, Turkey, has integrated the LX-K9 laser cutting machine into their production line. Their facility specializes in high-quality ladder production, processing 20x40mm oval tubes for various ladder components.

Production Requirements

- Primary material: 20x40mm oval tubes

- Application: Ladder component manufacturing

- Key focus: Consistent quality and efficient production

Application Overview

In Cakmak’s daily production, the LX-K9 primarily handles the precision cutting of oval tubes used in ladder assembly. The machine processes numerous 20x40mm oval tube components, which form the essential structural elements of their ladder products.

Daily Operation

The production team at Cakmak particularly appreciates several aspects of their LX-K9:

- The machine’s 1.5G acceleration enables them to maintain a steady production pace throughout their shifts

- The ultra-short tail design helps them maximize material usage, reducing waste in their oval tube processing

- The FSCUT system allows operators to easily adjust and maintain cutting parameters

Production Impact

Since implementing the LX-K9, Cakmak has observed several improvements in their production process:

- More efficient processing of 20x40mm oval tubes

- Better material utilization

- Consistent component quality

- Smoother production flow

- Reduced material handling time

Practical Applications

The facility regularly produces various ladder components using their LX-K9 system. The machine’s capabilities have proven particularly valuable in:

- Processing oval tubes for ladder rails

- Cutting precise lengths for different ladder models

- Maintaining consistent quality across production batches

Implementation Results

The integration of the LX-K9 into Cakmak’s production line has supported their ladder manufacturing operations by providing:

- Reliable daily operation

- Consistent cutting quality

- Efficient material processing

- Simplified production workflow

The machine has become an integral part of their manufacturing process, supporting their ongoing production of high-quality ladder components.