In today’s manufacturing industry, steel tube making machines represent a cornerstone of modern production technology, enabling the creation of high-quality tubes and pipes that form the backbone of numerous industries. Whether you’re involved in construction, automotive manufacturing, or industrial production, understanding these sophisticated machines is crucial for making informed decisions about your manufacturing processes.

What is Steel Tube Making Machine?

A steel tube making machine, also known as a tube mill machine, is specialized equipment designed for manufacturing steel tubes and pipes. These machines can produce various types of tubes, including round, square, and rectangular profiles, making them versatile tools in modern manufacturing.

What is the Difference Between Tube Making and Pipe Making Machines?

While many people use the terms “tube” and “pipe” interchangeably, in the manufacturing world, there are significant differences between tube making and pipe making machines. Let’s explore these differences in detail:

1. Product Characteristics and Design Focus

Tube Making Machines:

- Designed for versatility in shape production (round, square, rectangular, oval)

- Focus on precise dimensional control for mechanical applications

- Typically produce products with thinner walls relative to their diameter

- Often create tubes with smoother surface finishes

- Can handle more specialized materials and finishes

Pipe Making Machines:

- Primarily focused on producing round pipes

- Optimized for pressure-bearing applications

- Generally create products with thicker walls

- Emphasis on internal surface quality

- Designed specifically for fluid and gas transportation

2. Manufacturing Process Differences

Tube Making Machines:

- Employ more flexible forming sequences to accommodate various shapes

- Use specialized tooling for different profiles

- Often incorporate more sophisticated size control mechanisms

- Include multiple forming stages for complex shapes

- Feature adaptable welding systems for different materials

Pipe Making Machines:

- Utilize simpler forming sequences focused on round profiles

- Employ specialized pressure testing equipment

- Include systems for internal coating applications

- Focus on weld integrity for pressure applications

- Feature dedicated threading capabilities

3. Application-Specific Features

Tube Making Machines:

- Include quick-change tooling for different profiles

- Feature advanced surface finish controls

- Offer greater flexibility in size changes

- Provide options for decorative finishes

- Include systems for complex end forming

Pipe Making Machines:

- Incorporate pressure testing stations

- Feature specialized coating systems

- Include threading and coupling equipment

- Offer hydrostatic testing capabilities

- Focus on corrosion protection features

4. Industry Applications

Tube Making Machines Serve:

- Automotive industry (structural components, exhaust systems)

- Furniture manufacturing (frames, supports)

- Architectural applications (railings, decorative elements)

- Industrial machinery (mechanical components)

- Consumer products (appliance parts, sporting goods)

Pipe Making Machines Focus On:

- Oil and gas industry (transmission lines)

- Water distribution systems

- Industrial fluid transport

- Chemical processing plants

- HVAC systems

5. Quality Control Emphasis

Tube Making Machines:

- Focus on dimensional accuracy

- Emphasize surface finish quality

- Control mechanical properties

- Monitor shape consistency

- Check cosmetic appearances

Pipe Making Machines:

- Prioritize pressure testing

- Focus on weld integrity

- Test for fluid tightness

- Monitor wall thickness consistency

- Check threading quality

Key Components of Steel Tube Making Machines

A modern tube mill machine integrates several sophisticated components that work together in perfect harmony to produce high-quality tubes:

1. Uncoiler System

The uncoiler system acts as the starting point of the tube-making process. It features:

- Advanced tension control mechanisms for consistent material feeding

- Hydraulic or pneumatic expansion systems for coil support

- Precision braking systems for speed regulation

- Strip alignment guides for proper material positioning

2. Forming Section

The forming section represents the heart of the tube mill machine, where the actual shaping occurs:

- Multiple forming stands with precision-engineered roll profiles

- Progressive forming sequences for optimal material flow

- Adjustable roll positions for different tube sizes

- Advanced lubrication systems for reduced wear

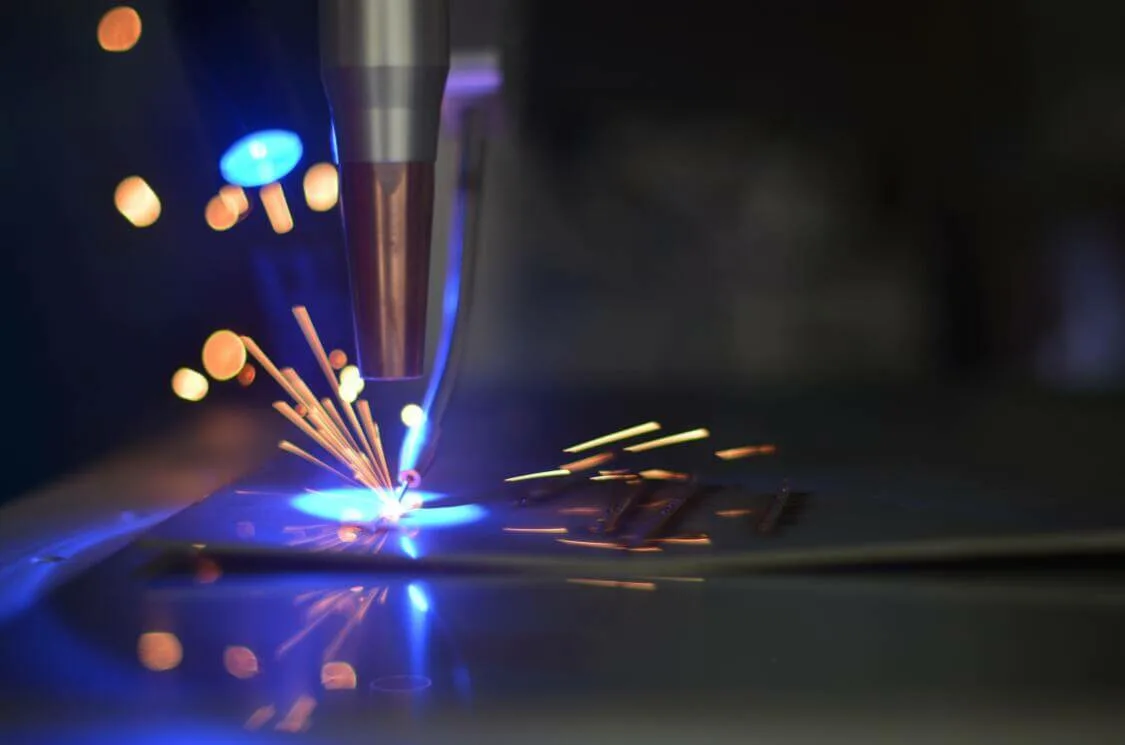

3. Welding Unit

The welding system ensures the structural integrity of the produced tubes:

- High-frequency welding capabilities for rapid production

- Precise edge alignment mechanisms

- Real-time weld monitoring systems

- Cooling systems for weld temperature control

4. Sizing and Straightening Unit

This unit ensures the final product meets exact specifications:

- Multi-roll sizing stands for dimensional accuracy

- Advanced straightening systems for product alignment

- Precision measurement systems for quality control

- Automated adjustment capabilities

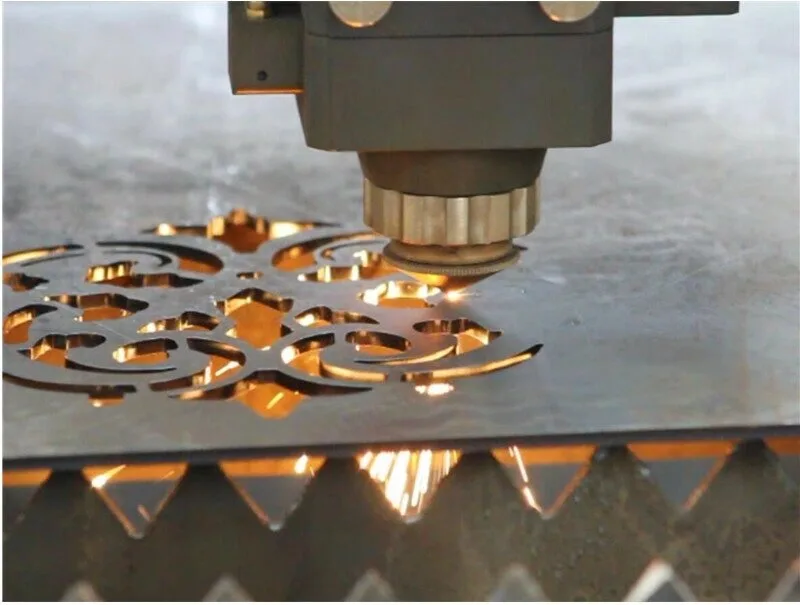

5. Cutting System

The cutting system provides precise length control:

- Flying cut-off systems for continuous production

- Length measurement systems for accuracy

- Automated synchronization with line speed

- Clean cutting mechanisms for quality finish

How Does The Steel Tube Making Machines Work?

The tube making process is a fascinating journey from flat steel strips to perfectly formed tubes. Let’s break down this complex process into detailed steps to understand how these sophisticated machines transform raw materials into finished products.

1. Material Feeding and Preparation

The process begins at the uncoiler station, where large coils of steel strip material are carefully loaded. This stage is crucial for the entire manufacturing process:

- The uncoiler supports the steel coil while expanding it hydraulically or pneumatically

- A specialized braking system, using either pneumatic or hydraulic cylinders, controls the feeding speed

- The steel strip passes through a straightening device to remove any coil set

- Entry guides align the strip properly before it enters the forming section

2. Strip Edge Preparation and Joining

For continuous production, the machine needs to handle multiple coils efficiently:

- When one coil is nearly finished, the machine prepares to join it with a new coil

- A shear device cuts both the trailing end of the depleting coil and the leading end of the new coil

- The cut ends are precisely aligned and welded together

- An accumulator system stores enough strip material to allow continuous production during the joining process

3. Progressive Forming Process

This is where the flat strip begins its transformation into a tubular shape:

- The strip first enters breakdown rolls, which gradually begin curving the edges upward

- Multiple forming stands progressively shape the strip through carefully designed roll profiles

- Each set of rolls incrementally increases the bending angle

- The process continues until the strip edges are brought close together, forming a circular, square, or rectangular profile

- Special fin passes help achieve precise edge alignment before welding

4. Welding Operations

The welding stage is critical for creating a strong, continuous tube:

- The edges of the formed tube are precisely aligned at the welding point

- For high-frequency welding, an inductor heats the edges to welding temperature

- Squeeze rolls apply pressure to forge the heated edges together

- Immediate cooling follows to control the metallurgical properties of the weld

- Internal and external scarfing tools remove excess weld material

5. Sizing and Calibration

After welding, the tube goes through several finishing stages:

- The welded tube enters the sizing section where multiple roll stands fine-tune the dimensions

- Turk’s head rolls with four precisely positioned rollers ensure perfect roundness or squareness

- The tube passes through straightening rolls to eliminate any bow or twist

- Inline measurement systems continuously monitor tube dimensions

6. Final Processing and Quality Control

The final stage involves several crucial steps:

- A flying cut-off saw cuts the continuous tube into precise lengths (typically 6m or custom lengths)

- Each cut piece moves to an inspection station for quality control

- Automated systems check for proper dimension, straightness, and weld integrity

- Surface inspection ensures the tube meets finish requirements

- Conveyor systems transport finished tubes to the collection and packaging area

7. Real-time Process Control

Throughout the entire operation, sophisticated control systems:

- Monitor and adjust machine parameters in real-time

- Control the strip tracking and alignment

- Regulate welding parameters for optimal joint quality

- Maintain proper tension throughout the line

- Coordinate all operations for seamless production flow

Applications and Industries

The versatility of steel tube making machines makes them invaluable across numerous industries:

Construction Sector

In construction, these machines produce tubes for:

- Structural support systems in buildings

- Framework for commercial structures

- Infrastructure components

- Building services conduits

Automotive Industry

The automotive sector relies on tube mill machines for:

- Exhaust system components

- Structural frame elements

- Fluid transport systems

- Safety cage components

Oil and Gas Industry

This sector utilizes tubes for:

- Transport pipelines

- Processing equipment

- Storage systems

- Offshore platforms

Furniture Manufacturing

Modern furniture production depends on tubes for:

- Frame construction

- Support structures

- Decorative elements

- Custom design components

Benefits and Advantages

Modern tube mill machines offer significant advantages in manufacturing:

Production Efficiency

- Continuous production capabilities reduce downtime

- High-speed operation increases output

- Automated systems minimize labor requirements

- Reduced material waste through precise control

Versatility in Manufacturing

- Multiple product profiles from a single machine

- Quick changeover capabilities

- Various size ranges possible

- Different material compatibility

Quality Consistency

- Precise dimensional control throughout production

- Consistent weld quality through automated processes

- Superior surface finish control

- Reliable product specifications

Conclusion

Steel tube making machines represent a crucial advancement in manufacturing technology. Their sophistication and versatility make them indispensable in modern industry. As technology continues to evolve, we can expect these machines to become even more advanced, offering improved capabilities and efficiency.

Understanding the intricacies of these machines – from their components and working principles to their applications – is essential for manufacturers looking to optimize their production processes. Whether you’re in construction, automotive manufacturing, or any other industry requiring steel tubes, selecting the right tube mill machine can significantly impact your production quality and efficiency.