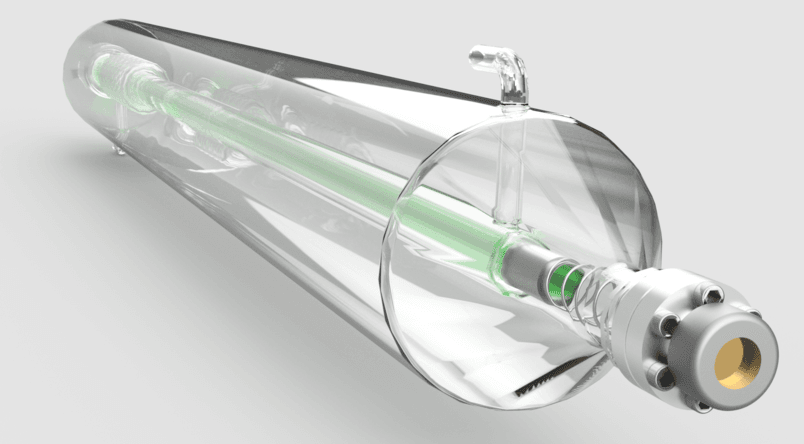

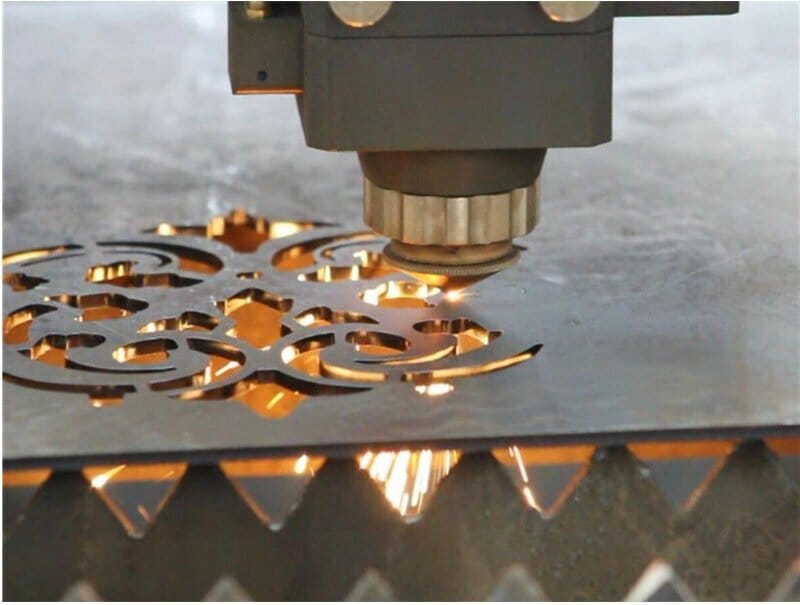

Most users pay more attention to the annealing process when purchasing a laser cutting machine, because the annealing process is conducive to the stability of the performance of the laser cutting machine. So what is the annealing process of the laser cutting machine?

What is Annealing?

The so-called annealing process is to heat the steel to a specific high temperature and keep it at this temperature for a period of time, and then slowly cool it down. This is called annealing. Annealing of steel is a heat treatment method that heats the steel to a temperature where phase change or partial phase change can occur, and then slowly cools it after keeping it warm.

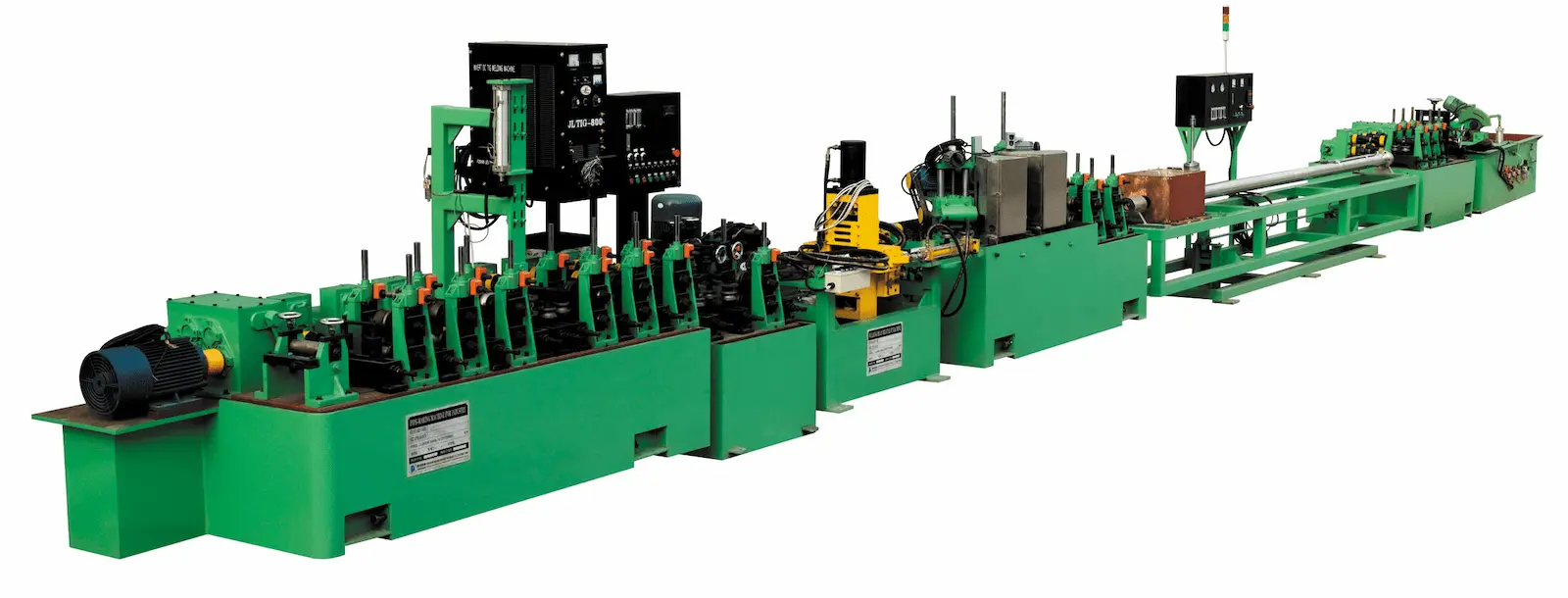

In the manufacturing process of CNC machine tools, the heat treatment process of castings is a crucial link. It is directly related to the final performance and service life of the castings.

Heat treatment is to adjust the internal structure and properties of metal materials by controlling the process of heating, heat preservation and cooling. For CNC machine tool castings, the main goal of the heat treatment process is to improve its hardness, strength, wear resistance and other properties to meet the use requirements under complex working conditions.

Common heat treatment processes include annealing, normalizing, quenching and tempering.

- Annealing is mainly to eliminate stress inside the casting, reduce hardness and improve processing performance.

- Normalizing is to control the heating temperature and time to make the casting obtain a certain hardness and strength and improve its wear resistance.

- Quenching is to heat the casting to above the critical temperature and then cool it quickly to obtain high hardness and strength characteristics, but this process is prone to deformation and cracking of the casting and needs to be operated with caution.

- Tempering is carried out after quenching to reduce the brittleness of the casting and improve its toughness and toughening hardness.

Why Anneal?

Annealing of machine bed castings, also known as low-temperature annealing, is mainly used to eliminate residual casting stresses in machine tool castings such as machine beds, worktables, components, and other castings. If these stresses are not eliminated, they can cause deformation or cracking during subsequent machining or use over time. To reduce the tendency of deformation and cracking during use and subsequent processing, castings are usually annealed after being removed from the mold to remove casting stresses.

Objectives of the Annealing Process

The objectives of annealing are to reduce structural defects, improve the uniformity of composition, refine grain size, enhance the mechanical properties of steel, and reduce residual stresses. Additionally, annealing can lower hardness, increase the plasticity and toughness of the material, and improve machinability.

Therefore, annealing not only addresses defects and stresses from previous processes but also prepares the material for subsequent operations.The annealing process is one of the methods to extend the service life of laser cutting machine beds, enhancing their physical properties and ensuring high-quality production of laser cutting machines.

Classification of Annealing Methods

Annealing is a heat treatment process used to alter the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. The commonly used methods of annealing can be broadly classified into two categories: annealing involving phase change above the critical temperature and annealing below the critical temperature.

Annealing Above the Critical Temperature

Complete Annealing:

Involves heating the steel to a temperature above its critical point, maintaining it for a specific period, and then slowly cooling it in the furnace. This process results in a uniform and refined microstructure.

Diffusion Annealing:

The material is heated to a high temperature and held for an extended period to allow the diffusion of atoms, which helps in homogenizing the chemical composition and eliminating segregation.

Incomplete Annealing:

Similar to complete annealing but the temperature is slightly below the critical point, resulting in partial phase transformation.

Isothermal Annealing:

The material is heated to above the critical temperature and then cooled rapidly to a temperature below the critical point, where it is held until transformation is complete. This method is used to refine the grain structure.

Spheroidizing Annealing:

Aimed at producing a spheroidal or globular form of carbide in steel, making it easier to machine. This is particularly useful for high-carbon steels.

How to Choose a Suitable Annealing Process?

Choosing the right annealing process for your material is crucial to achieving the desired mechanical properties and ensuring optimal performance in subsequent manufacturing steps. Here are some key considerations and steps to help you select the most appropriate annealing method:

1. Understand the Material Composition

Different materials respond differently to heat treatment. Knowing the composition of your material is the first step in selecting an appropriate annealing process. For example:

- Steel: Commonly requires processes like full annealing, isothermal annealing, or stress relief annealing.

- Non-ferrous metals: Such as copper and aluminum, may require different cooling rates and temperatures.

2. Determine the Desired Mechanical Properties

Identify the specific mechanical properties you need to achieve, such as:

- Hardness: Reduced hardness for easier machining.

- Ductility: Increased ductility for better formability.

- Strength: Appropriate balance of strength and toughness.

3. Assess the Current Condition of the Material

Consider the current state of the material, including any existing internal stresses or work hardening. This will help determine the necessity and type of annealing process required.

4. Evaluate the Process Requirements

Each annealing process has specific requirements and outcomes. Here are some common annealing methods and their applications:

Full Annealing

- Process: Heat the steel to 20-30°C above the Ac3 temperature, hold, then slowly cool in the furnace.

- Used for: Hypoeutectoid steels (0.3-0.6% carbon), castings, forgings.

- Objective: Refine grain size, homogenize structure, reduce hardness, improve machinability.

Isothermal Annealing

- Process: Heat above Ac3 (or Ac1), cool to the pearlite region, hold, then cool to room temperature.

- Advantage: Shorter process time compared to full annealing.

- Suitable for: High-carbon steel (>0.6% C), alloy tool steel, high-alloy steel (>10% alloy elements).

Stress Relief Annealing

- Process: Heat steel to 500-650°C (below Ac1), hold, then cool slowly in the furnace.

- Objective: Eliminate residual internal stresses without structural changes.

Spheroidizing Annealing

- Used for: Eutectoid and hypereutectoid steels (e.g., carbon tool steel, bearing steel).

- Process: Heat to 20-30°C above Ac1, hold for 2-4 hours, then cool slowly.

- Objective: Reduce hardness, improve machinability, prepare for hardening.

Recrystallization Annealing

- Also known as: Intermediate annealing.

- Process: Heat cold-worked steel above the recrystallization temperature (about 450°C for steel).

- Objective: Restore ductility, reduce hardness, eliminate work hardening effects.

Diffusion Annealing (Homogenizing Annealing)

- Process: Heat to just below the solidus line for 10-15 hours, then cool slowly.

- Temperature: 100-200°C above Ac3 or Accm.

- Objective: Eliminate segregation, homogenize composition.

Partial Annealing

- Process: Heat between Ac1 and Ac3 (or Accm), hold, then cool slowly.

- Main use: Obtain spheroidized pearlite in hypereutectoid steel.

- Objective: Eliminate internal stresses, reduce hardness, improve machinability.

5. Consider Equipment Availability and Cost

Evaluate the availability of suitable heat treatment equipment and facilities. Also, consider the cost implications of the annealing process, balancing the benefits of improved material properties with the expenses involved in the process.

6. Review Safety and Environmental Factors

Ensure that the chosen annealing process complies with safety standards and environmental regulations. Some processes may produce harmful by-products or require specific safety measures.

7. Plan for Subsequent Manufacturing Steps

Consider how the annealed material will be used in subsequent manufacturing steps. The chosen annealing process should prepare the material for further processing, such as machining, forming, or additional heat treatments.

Conclusion

Selecting the right annealing process involves understanding the material composition, desired mechanical properties, current material condition, and specific requirements of each annealing method. By carefully evaluating these factors, you can choose an annealing process that optimizes the performance and workability of your material, ensuring successful manufacturing outcomes.