As we all know, due to its accuracy, stability, safety, purity and other characteristics, the special metals used in the manufacture of medical devices are often difficult to process or the material cost is high, which places higher requirements on processing and processing equipment.

The traditional mechanical pipe cutting processing mode has great shortcomings in terms of accuracy and safety controllability, but laser cutting can successfully overcome these challenges. The laser cutting head will not come into contact with the surface of the material being processed, and will not scratch the workpiece. If the surface polishing process of device products can be minimized during processing, production efficiency will be greatly improved.

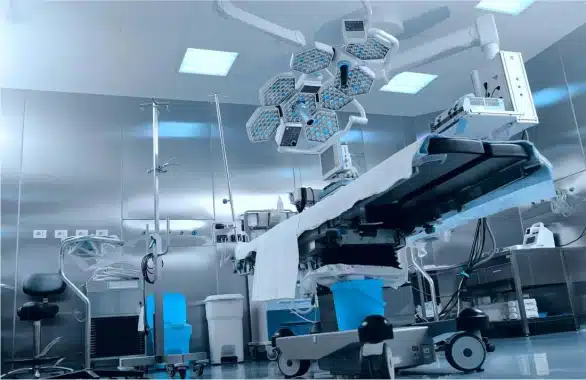

Currently, laser cutting has a wide range of uses in the medical industry, including medical production equipment and equipment, cutting precision tubes, and surgical applications that require sterility and precise cutting.

Longxin high-precision laser cutting machine escorts the safety of human life. Due to its extremely small laser beam, it can process very small parts and cut parts with high aspect ratios.