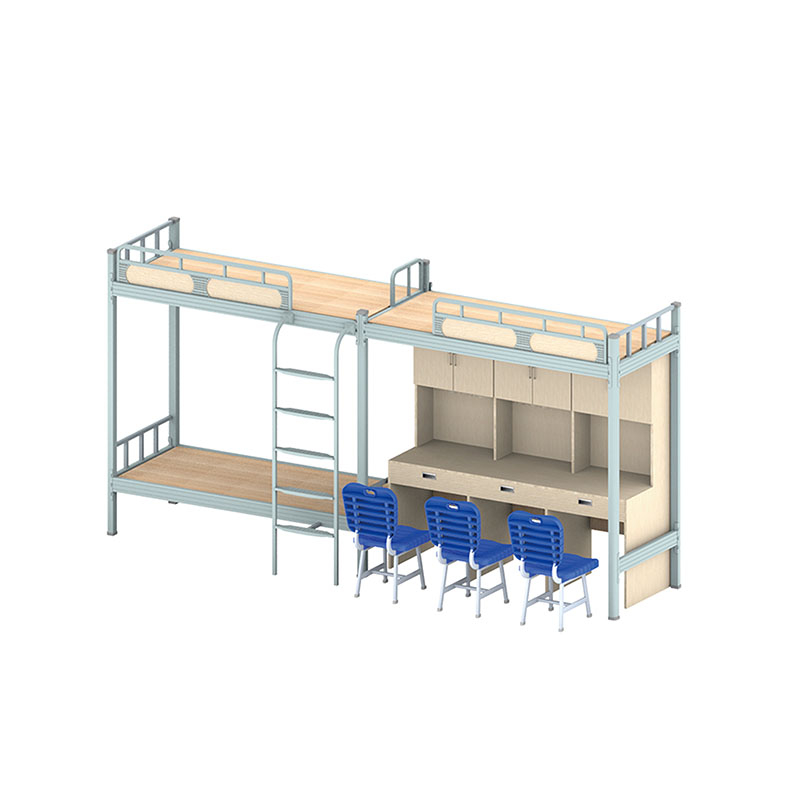

A renowned school furniture manufacturer based in Bazhou, China, specializes in producing high-quality beds and furniture for educational institutions. The company has been striving to innovate its production processes to maintain a competitive edge in the market.ChallengesThe manufacturer faced several challenges, including:

- Increasing the efficiency of cutting non-standard and small-diameter steel tubes.

- Improving cutting quality to reduce subsequent processing steps.

- Minimizing material waste to enhance raw material utilization.

- Enhancing production flexibility to meet varying order specifications.

Solution

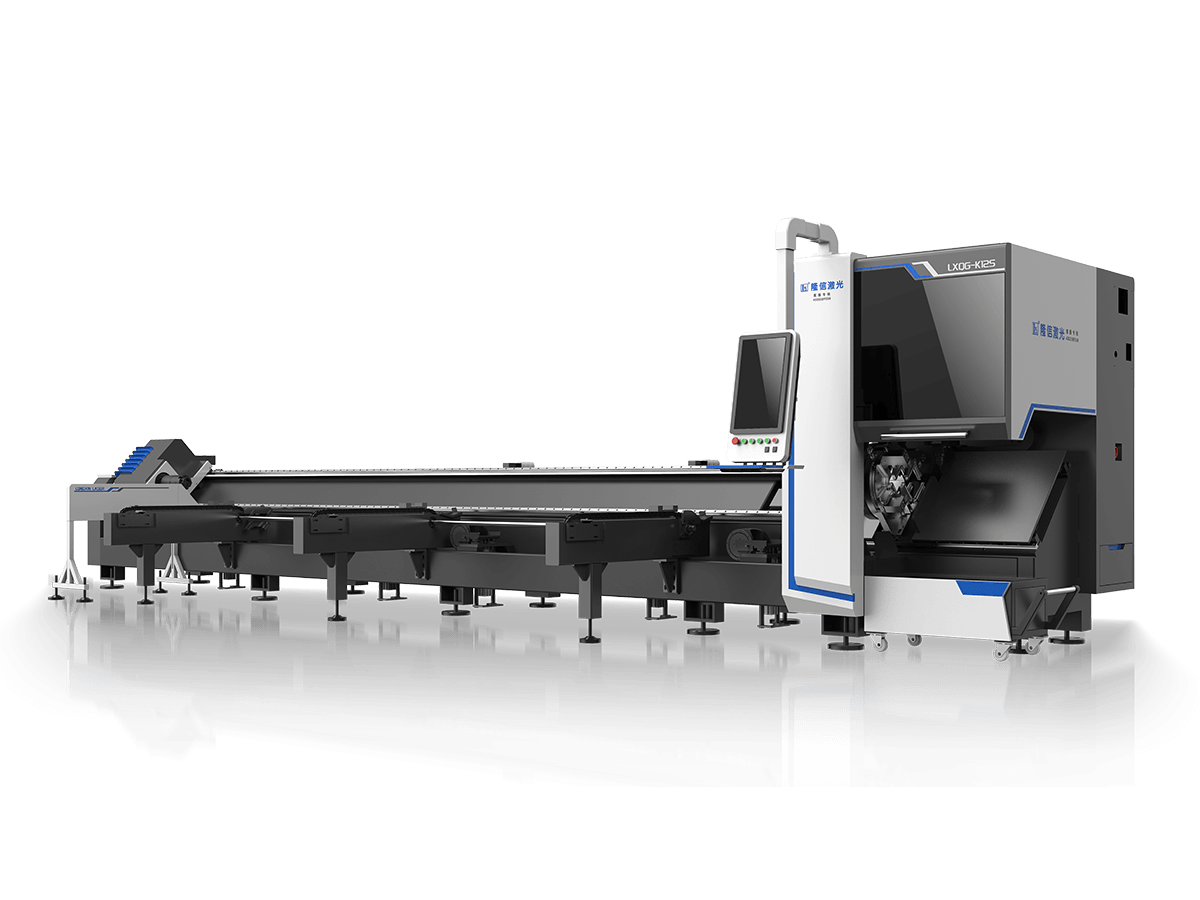

To address these challenges, the company adopted the LX-K12S high-speed laser tube cutting machine from Longxin Laser. This machine offers several advanced features:

- L-shaped bed design with side-mounted front chuck: Enhances stability and precision.

- 1.0G acceleration: Allows for synchronized feeding during cutting, significantly increasing speed.

- High material utilization: Reduces production costs by optimizing material usage.

- Robust machine structure: Ensures high cutting accuracy.

Implementation

The LX-K12S was integrated into the production line to process specific tube materials:

- 40×80×1.3mm non-standard tubes

- 15×30×1.0mm steel tubes

Results

The implementation of the LX-K12S laser tube cutting machine brought significant improvements:

- Efficiency: The machine efficiently handled the specified tube materials, increasing cutting speed by 200% compared to traditional methods.

- Precisione: Achieved cutting accuracy of ±0.1mm, reducing the need for additional finishing processes.

- Material Utilization: Enhanced material utilization by 15%, lowering raw material costs.

- Flexibility: The machine’s flexible programming system allowed for quick changes between different tube specifications and shapes.

Customer Benefits

By adopting the LX-K12S laser tube cutting machine, the school furniture manufacturer realized several benefits:

- Increased Production Efficiency: Production efficiency improved by 150%, significantly reducing delivery times.

- Enhanced Product Quality: Consistent cutting precision led to higher product quality and customer satisfaction.

- Cost Savings: Material costs were reduced by 12%, boosting overall profitability.

- Improved Flexibility: The ability to quickly adapt to different order specifications enhanced the company’s responsiveness to market demands.

The client expressed their satisfaction, stating, “The LX-K12S has revolutionized our production process. It not only increased our efficiency but also helped us maintain a competitive edge in the market.”This case study demonstrates the exceptional performance of the LX-K12S high-speed laser tube cutting machine in the school furniture manufacturing industry, providing a valuable reference for similar manufacturing enterprises.