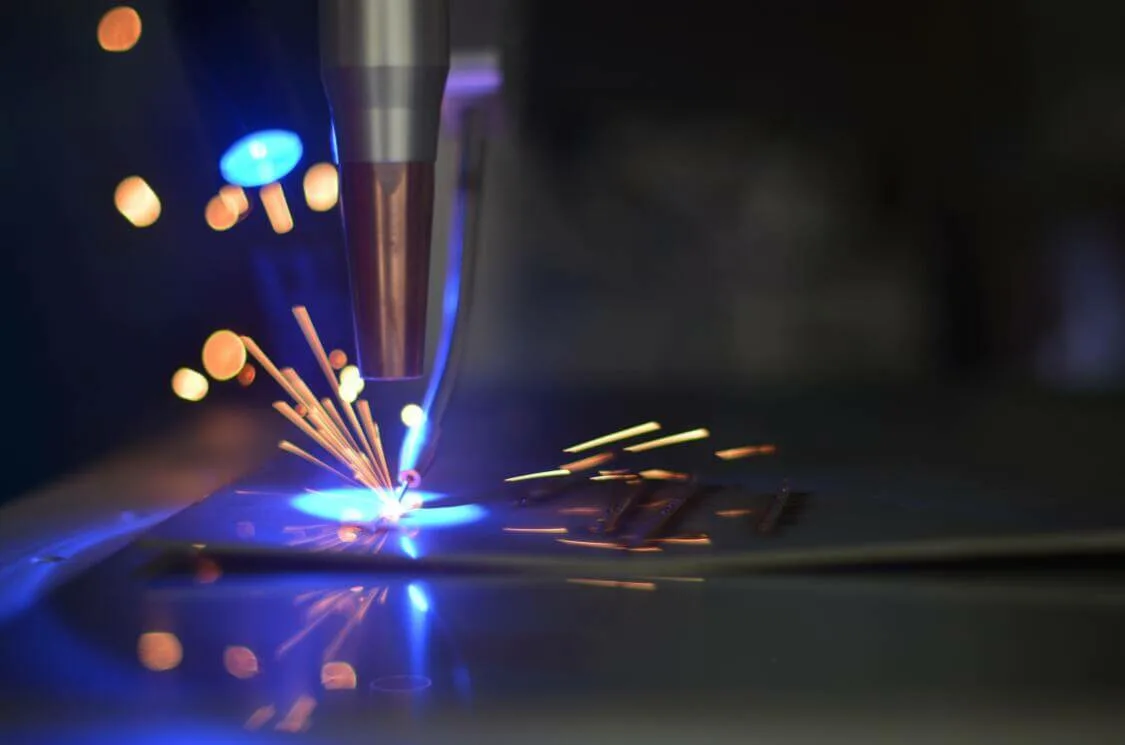

Traditional pipe processing often relies on methods like sawing and punching. However, these approaches can leave behind burrs, slag, and imprecise hole diameters that struggle to meet modern industrial demands. The advent of レーザーチューブ切断機 has revolutionized pipe processing, offering a solution that delivers smooth cut surfaces and highly flexible hole sizes to accommodate diverse factory needs.

While laser tube cutting machines unlock new possibilities, there are also important techniques to master for optimal performance, especially when it comes to the delicate process of hole piercing. Here are some key considerations to keep in mind:

Servo Motor Precision is Paramount

Poorly calibrated servo motors can cause the laser to produce elliptical or irregularly shaped holes, rather than clean, circular openings. This mismatch in X-Y axis motion is often traced back to improper servo motor parameter settings. Ensuring the servo motors are precisely tuned is crucial for achieving the cutting quality that laser tube cutting machines are capable of.

Finding the Sweet Spot for Assist Gas

The cutting process relies on assist gases to optimize performance, but getting the pressure just right is critical. Too little assist gas pressure can lead to burrs, slag, and even carbon buildup on the workpiece. Conversely, overly high pressure increases the risk of blowouts during hole piercing. Operators must learn to meticulously adjust the assist gas pressure to strike the perfect balance.

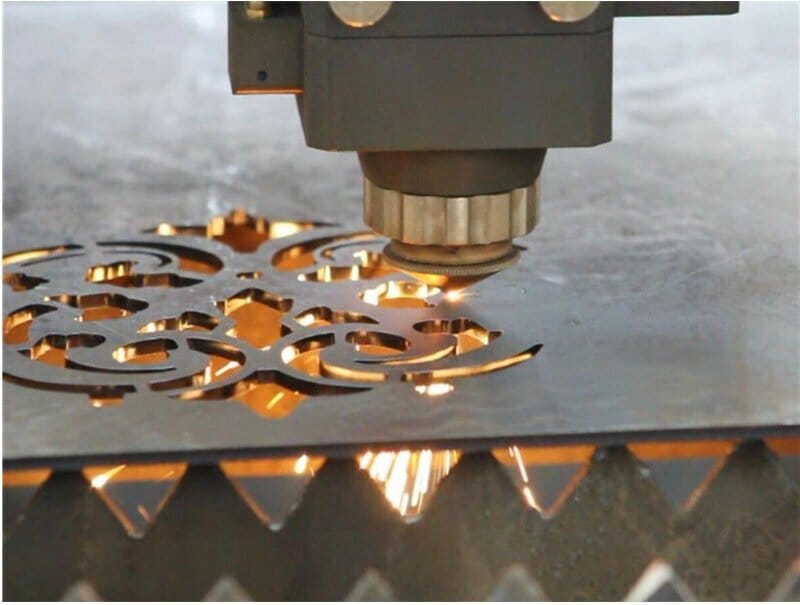

Hole Size Matters

There is an optimal ratio between hole diameter and material thickness for laser tube cutting – about 1:1. Larger diameter holes tend to yield higher quality circular openings, while smaller holes are more prone to incomplete piercing and irregularities. Understanding this sizing dynamic allows operators to set hole dimensions that capitalize on the machine’s capabilities.

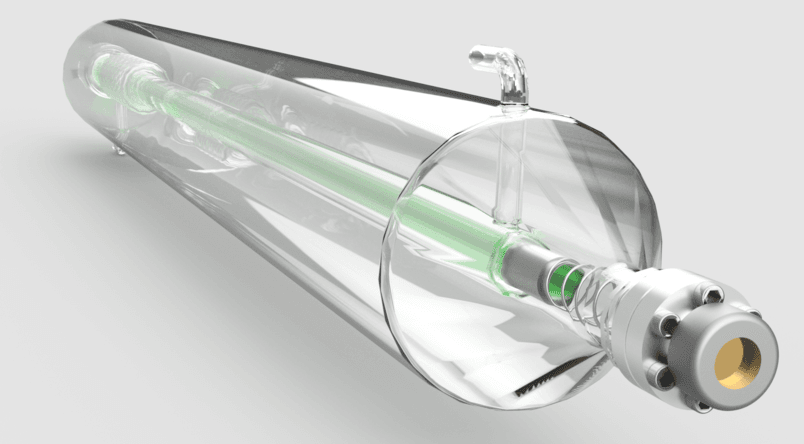

Precision Components are Non-Negotiable

Servo motors aren’t the only critical components – the accuracy of guide rails and lead screws also directly impacts hole drilling precision. When specifying or purchasing laser tube cutting machines, it’s essential to prioritize high-quality, brand-name parts that maintain tight tolerances. Skimping on component quality can severely compromise the machine’s overall performance.

By mastering these key techniques, manufacturers can unleash the full potential of their laser tube cutting machines, producing consistent, high-quality parts that meet the most demanding industry requirements. With a keen eye for detail and a commitment to ongoing optimization, the path to laser tube cutting excellence is within reach.