On September 23, 2025, Longxin Laser officially unveiled China’s first water-guided laser tube cutting machine at the Shanghai International Industry Fair. This revolutionary equipment marks a pivotal leap for China, transitioning from follower to leader in the field of ultra-precision laser processing.

Technological Breakthrough: Overcoming Key Bottlenecks with Three Major Innovations

Fully In-House Core Technology Development

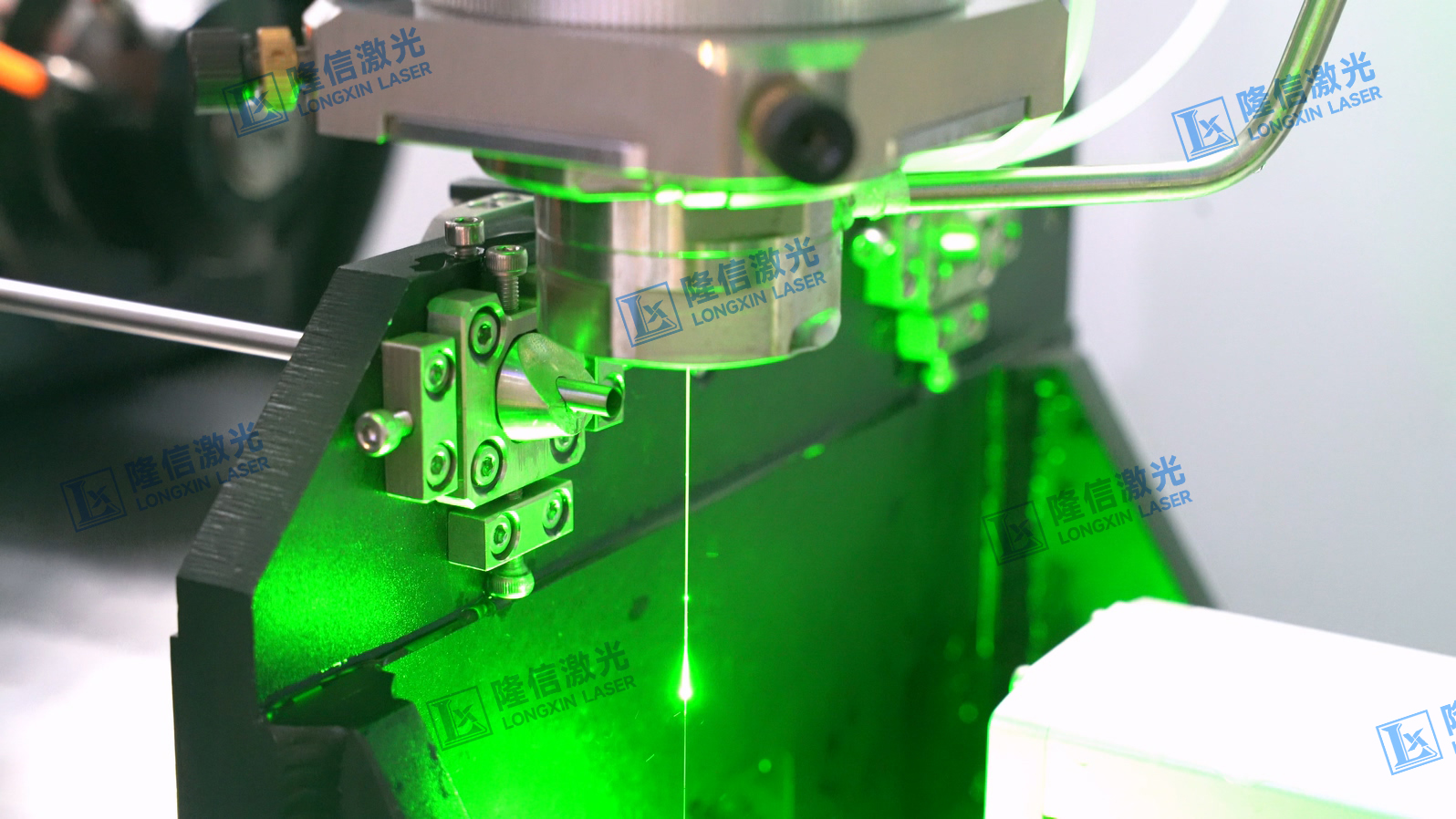

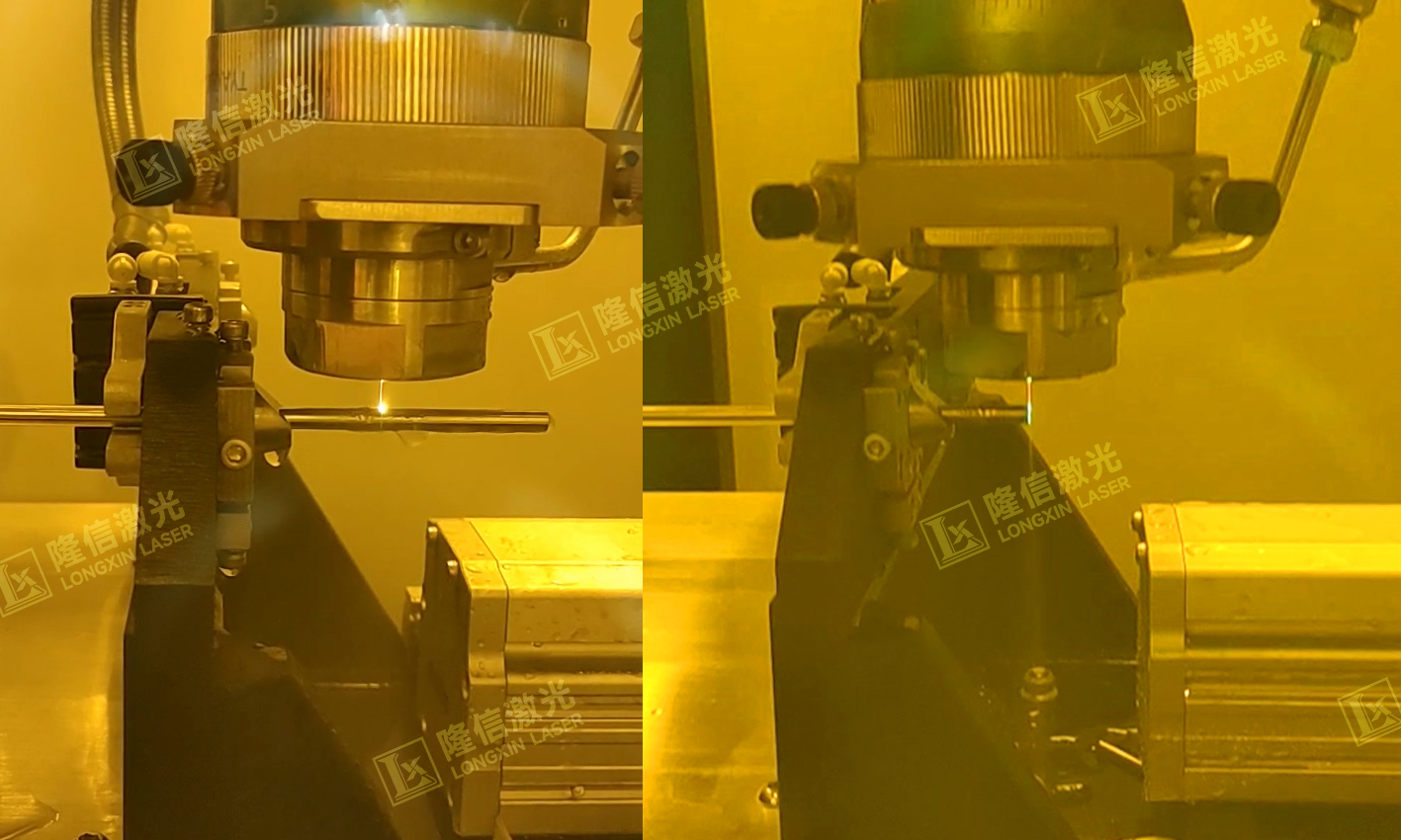

The R&D team at Longxin has developed a water-guided laser system with complete in-house capabilities, including the water-guided laser optical path system, coupling chamber, nozzle, and high-pressure water circulation system—all designed, manufactured, and produced internally.

Breakthrough in Opto-Fluid Coupling Technology

Featuring a proprietary water-guided laser coupling chamber structure, the system achieves water jet stability at internationally leading levels. It enables stable water beam diameters of 30-120 μm, with selectable green light laser powers ranging from 60-400 W (adjustable from 0-100%). This supports ultra-precision processing of tubes with diameters from φ0.5-12 mm to an accuracy of ±0.005 mm, and surface roughness better than Ra 0.8 μm for certain materials. Within the φ0.5-12 mm diameter range (with customizable models available for φ60 mm bars and tubes), it processes both tubes and solid bars. The unique optical design extends nozzle lifespan by 300% compared to domestic peers, fundamentally addressing the high consumable costs plaguing traditional water-guided laser equipment.

Completely Clean, Residue-Free Processing

Burrs and slag adhesion on tube cuts, particularly on inner walls, have long been a global industry challenge. After years of dedicated research, Longxin Laser has fully resolved this issue with the launch of this product!

Breakthrough in Extreme Processing Capabilities

Leveraging high-pressure water jet stabilization technology for consistent 30-120 μm water beam diameters, paired with 60-400 W green light lasers (customer-selectable), the machine cuts metals, ceramics, silicon carbide, diamond, composites, and more. For select materials, it achieves extreme cutting depths exceeding 50 mm—far surpassing domestic competitors.

Market Value: Providing a Chinese Solution for High-End Manufacturing

The Longxin water-guided laser tube cutting machine redefines the foundational logic of processing technology. Applicable to leading sectors like precision semiconductors, aerospace, and medical devices, its three core advantages directly address industry pain points:

Efficiency Revolution: As a groundbreaking ultra-precision laser tube cutting machine, it delivers the same processing accuracy and quality as femtosecond laser systems. Yet, under equivalent precision and quality conditions, water-guided laser processing efficiency is at least three times that of femtosecond lasers.

- Cost Advantage: Full lifecycle maintenance costs reduced by 40%.

- Customization Capability: Open CNC system interfaces support secondary development.

Industry Outlook: Leading a New Ecosystem in Precision Processing

With surging demand for precision tubes in aerospace, semiconductors, and medical devices, Longxin Laser will forge industrial alliances with upstream and downstream partners. This series of water-guided laser tube cutting machines will accelerate the localization of products in areas like minimally invasive surgical instruments and aerospace conduits.

Primary Application Scenarios for the Longxin Water-Guided Laser Precision Tube Cutting Machine:

- Medical Field: Processing of various micro-tubes, such as cardiac stents, endoscopes, and snakebone tubes for interventional surgery;

- High-Precision Fluid Pipeline Processing Under Residue-Free Conditions: Such as micro-fluid tubes in aerospace and military applications requiring complete slag-free results;

- 3C Electronics, Semiconductors, and Other High-Precision Micro-Tube Processing: For scenarios demanding extreme accuracy.

Features and Advantages of the Longxin Water-Guided Laser Precision Tube Cutting Machine:

- Ultimate Processing Precision and Surface Quality: Capable of cutting tubes from φ0.5-12 mm with repeated positioning accuracy of ±5 μm; surface roughness better than Ra 0.8 μm for certain materials.

- Achieves Completely Residue-Free Cutting: Ideal for precision fluid pipelines of various micro-sizes.

- Compared to Traditional Tube Cutting Machines, Enables Processing of Hard and Brittle Materials with Low Chipping and Edge Breakage Rates: Traditional machines often cause edge breakage or chipping in such materials, but water-guided lasers handle them effectively—e.g., ceramic tubes or silicon carbide tubes common in semiconductors and nuclear industries. For silicon carbide tubes, edge breakage rates are below 0.01%, with minimum edge breakage dimensions as low as 3 μm.

- Breakthrough in Cold Processing of Difficult-to-Machine and Superhard Materials, with Minimal Micro-Cracks, Recast Layers, and Heat-Affected Zones (Less Than 10 μm): In medical applications, such as cutting titanium alloy micro-tubes for cardiac stents and snakebone tubes, it offers high precision, minimal heat-affected zones (<15 μm), and low slag adhesion rates. This balances efficiency with reduced heat impact, preventing material crystallization and oxidation to enhance blood compatibility (the world’s first device certified under ISO 10993 for biocompatibility was processed via water-guided laser).

- High-Precision Micro-Tube Processing for Materials with Inconsistent Melting and Vaporization Points, Including Composites: Such as carbon fiber reinforced polymers (CFRP) or ceramic matrix composites. In aerospace, precision cutting of CFRP achieves 40% higher efficiency and reduces scrap rates to 0.5%.

- Eco-Friendly Processing: High-speed water jets effectively remove laser-induced slag residues, yielding cleaner processing zones, superior surface quality, and enhanced precision. Additionally, water flow evacuates gaseous dust from evaporation, safeguarding the environment. The absence of metal dust during processing lowers the risk of respiratory occupational diseases like pneumoconiosis for operators.