1. 導入

1.1 Background

Laser technology has rapidly evolved over the past few decades, playing a critical role in scientific research, industrial manufacturing, medical diagnostics, communications, and defense. Among the various types of lasers, the tube laser—characterized by its tubular resonator design and efficient energy conversion—is emerging as a preferred solution for high-precision and high-stability applications.

1.2 Definition and Distinction

This guide focuses on tube lasers that employ a tube-shaped optical cavity to generate high-quality laser beams. It is important to note that “tube laser” here specifically refers to this type of laser device rather than laser tube cutting machines. We explore the physical principles, structural features, and application advantages of tube lasers.

1.3 Purpose and Structure of the Guide

This comprehensive guide is intended for researchers, industrial engineers, and laser technology enthusiasts. It details the working principles, core technologies, and application areas of tube lasers while also discussing recent innovations and future market trends. The article is organized as follows:

- Fundamentals and Principles: Basic laser concepts and tube laser design.

- Tube Laser Working Mechanism: Energy conversion and beam control.

- Technical Features and Performance Advantages: Key performance aspects such as beam quality, efficiency, and thermal management.

- Laser Categories and Application Fields: An introduction to various laser types and a discussion of where tube lasers are applied—including their role in laser cutting equipment.

- Latest Technological Advances and Innovation Trends: Breakthroughs in materials, pulsed laser technology, and smart control systems.

- Safety, Maintenance, and Operation Guidelines: Best practices for safe operation, maintenance, and troubleshooting.

- Market Status and Future Outlook: Current market dynamics, challenges, and prospects.

- Conclusion and Outlook: A summary of key points and future recommendations.

- Appendix: A glossary of relevant technical terms.

2. Fundamentals and Principles

2.1 Basic Laser Concepts

Laser (Light Amplification by Stimulated Emission of Radiation) generation is based on atomic or molecular energy transitions, where stimulated emission amplifies light. Three core elements are essential:

- Gain Medium: The material (gas, solid, semiconductor, or liquid) that produces stimulated emission.

- Pumping Source: An energy source (electrical, optical, etc.) that excites the gain medium.

- Resonant Cavity: Typically formed by a pair of mirrors, this cavity enables the repeated passage and amplification of light, resulting in a coherent beam.

2.2 Tube Laser Design and Structure

Tube lasers distinguish themselves through a tubular resonator design that offers several benefits:

- Enhanced Optical Coupling: The tube structure helps distribute the pump light evenly, optimizing energy transfer.

- Improved Thermal Management: The elongated tube aids in dissipating heat, reducing localized temperature rises and enhancing stability.

- Stable Beam Mode: The geometry of the tube supports the selection of specific laser modes, ensuring high beam coherence and uniformity.

Key components include high-quality mirrors, an effective cooling system, a precise pump assembly, and optical elements designed to control beam characteristics.

3. Tube Laser Working Mechanism

3.1 Energy Conversion and Laser Output

Tube lasers convert energy from an external source (electrical or optical) into excitation energy within the laser medium. As excited particles return to their ground state, they emit coherent photons through stimulated emission. These photons bounce between the mirrors in the tube, undergoing amplification until a high-intensity, coherent beam is produced.

3.2 Beam Generation and Control

The tube structure not only facilitates uniform energy distribution but also plays a critical role in controlling the laser mode:

- Mode Selection: The tubular cavity allows for the amplification of desired modes (typically the TEM00 mode), ensuring a high-quality Gaussian beam.

- Beam Shaping and Focusing: Adjustable optical components within the cavity enable fine control over beam diameter, divergence, and focusing properties.

- Thermal Compensation: Advanced thermal management ensures that the output wavelength and power remain stable during prolonged operation.

4. Technical Features and Performance Advantages

4.1 Beam Quality and Stability

Optimized tube laser designs deliver excellent beam quality, characterized by uniform intensity, low divergence, and high coherence. This stability is crucial for applications requiring precise and repeatable performance.

4.2 High Efficiency and Long Lifespan

By leveraging advanced pump technologies and optimized gain mediums, tube lasers achieve high energy conversion efficiency. Their robust thermal management systems further contribute to an extended operational lifespan, reducing maintenance costs.

4.3 Thermal Management and System Stability

Effective heat dissipation is essential in high-power laser systems. Tube lasers benefit from a design that disperses heat along the tube’s length, minimizing thermal gradients and ensuring consistent performance even under continuous operation.

5. Laser Categories and Application Fields

5.1 Introduction to Different Laser Categories

Before delving into the applications of tube lasers, it is useful to understand the broader laser landscape. Common laser types include:

- Solid-State Lasers: Utilizing solid gain mediums (e.g., Nd:YAG), these lasers are compact and easy to maintain, finding use in industrial and medical applications.

- Gas Lasers: Operating with gases like CO₂ or helium-neon, these lasers offer stable wavelengths ideal for cutting, engraving, and printing.

- Semiconductor Lasers: Compact and energy-efficient, they are widely used in telecommunications, laser printing, and consumer electronics.

- Fiber Lasers: Featuring a fiber-optic gain medium, these lasers provide excellent beam quality and efficient cooling, suitable for high-precision applications.

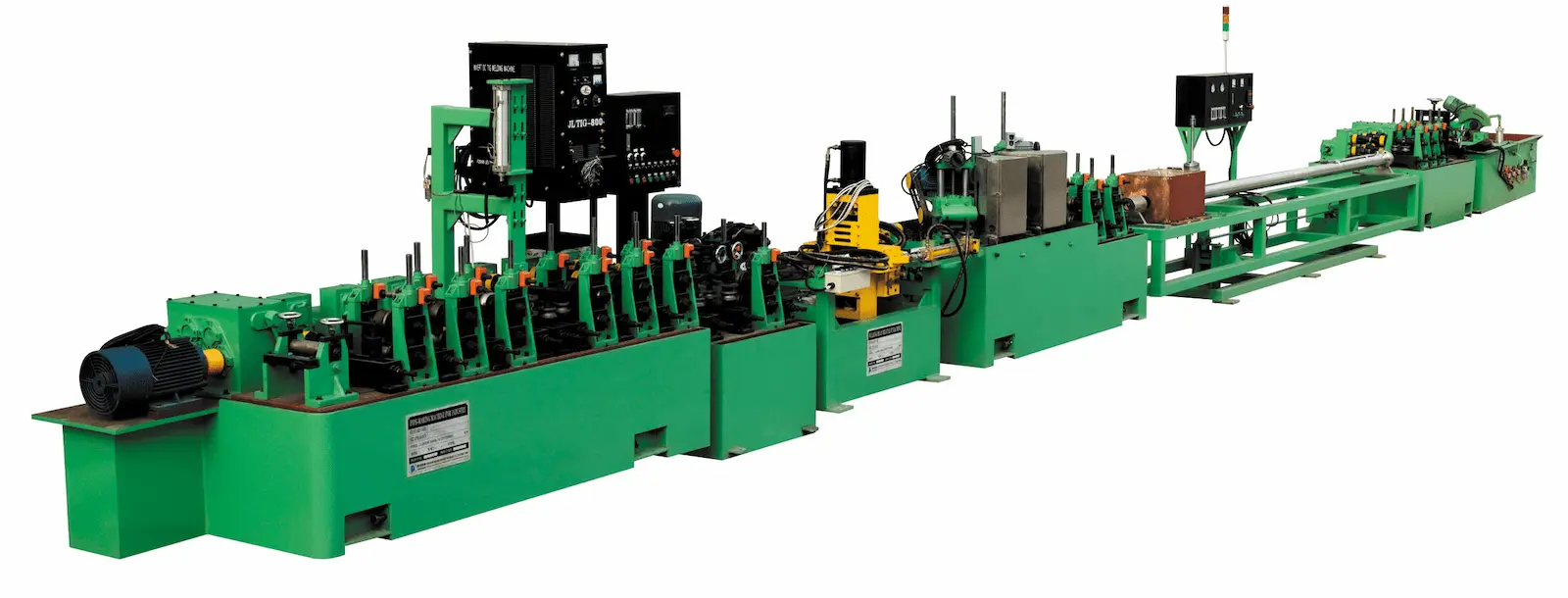

- Tube Lasers: With their tubular resonator design, tube lasers combine high conversion efficiency with excellent beam stability, making them ideal for demanding applications.

5.2 Application Fields

Tube lasers are widely utilized due to their stable, high-quality output and efficient energy conversion. Key application areas include:

-

Industrial Manufacturing and Processing

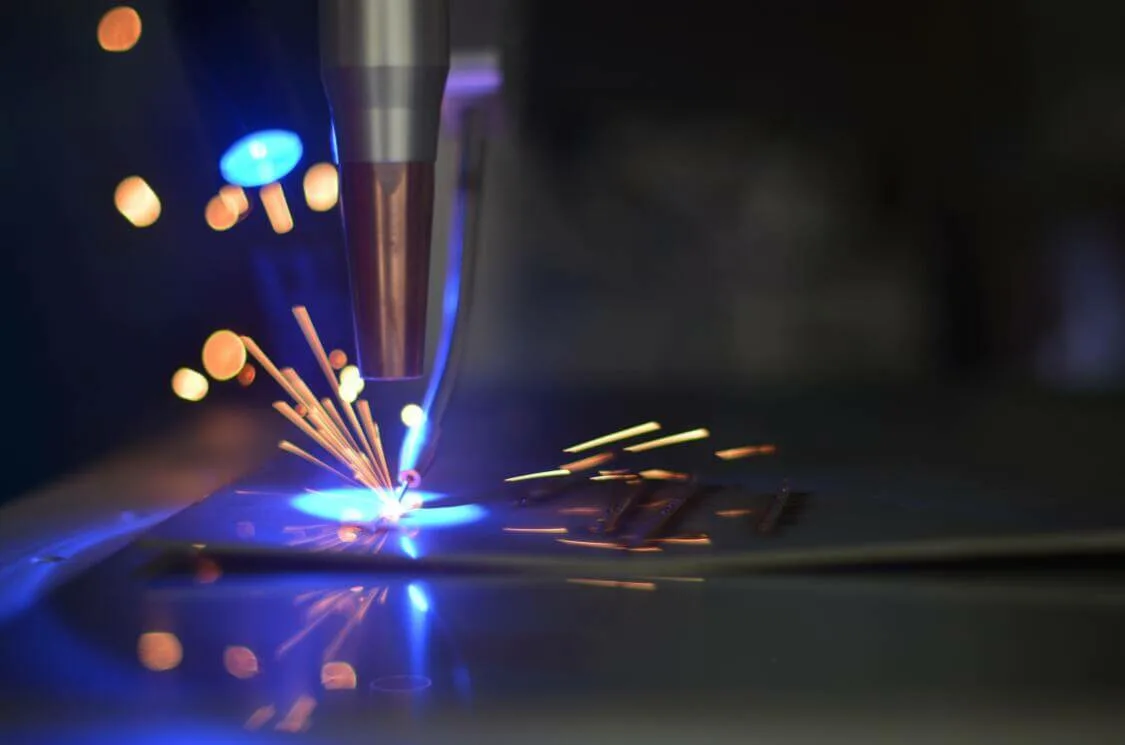

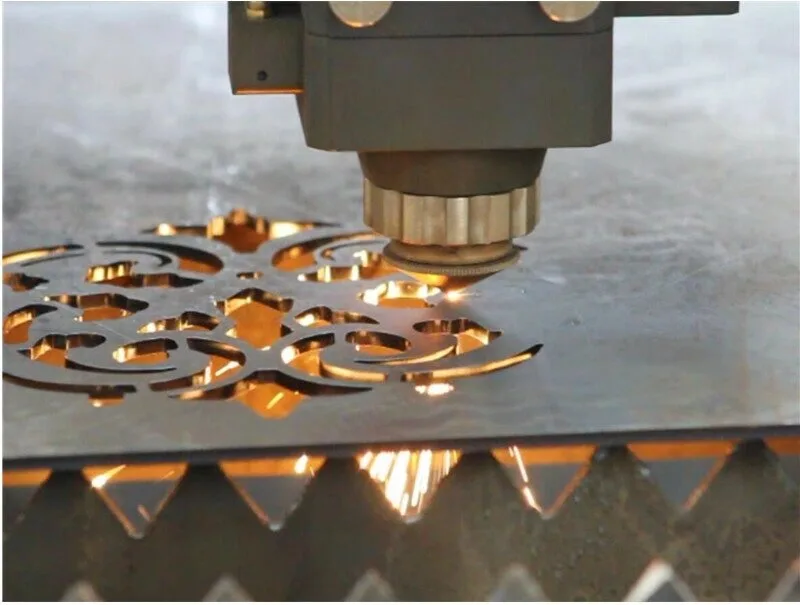

- Precision Welding and Marking: Tube lasers enable high-quality welding of metals and alloys, and their precise beams are perfect for engraving minute markings on product surfaces.

- Laser Cutting Equipment: With the capability to produce fine, precise cuts and minimal heat-affected zones, tube lasers are integral to advanced laser cutting systems used in diverse manufacturing processes.

-

Research and Precision Measurement

- Spectroscopy and Interferometry: The high coherence of tube lasers makes them ideal for detailed spectral analysis and interferometric measurements, capturing even minute displacements and vibrations.

- Laser Diagnostics: Used in environmental monitoring, fluid dynamics, and materials science, tube lasers facilitate high-precision measurements and imaging.

-

Medical and Biotechnology

- High-Resolution Imaging: Tube lasers serve as a stable light source in medical imaging equipment, such as endoscopes and microscopes.

- Minimally Invasive Surgery: Their precision allows for delicate surgical procedures, reducing damage to surrounding tissues and enabling therapies like photodynamic treatment.

-

Communication and Display

- Fiber-Optic Communication: Tube lasers provide the stable and coherent light necessary for high-speed data transmission over long distances.

- Laser Display Technologies: They are also used in holographic projection, laser televisions, and other advanced display systems to deliver high-brightness, high-contrast images.

6. Latest Technological Advances and Innovation Trends

6.1 New Materials and Processing Technologies

Emerging laser gain mediums and advanced optical coatings have significantly enhanced tube laser performance. Innovations in manufacturing techniques continue to improve damage thresholds and overall durability.

6.2 Pulsed Laser and Modulation Techniques

Advances in pulsed laser technology, including ultrafast pulses (in the nanosecond to picosecond range), enable tube lasers to meet the demands of precision micromachining and cutting-edge research.

6.3 Intelligent and Automated Control Systems

Integration of sensors, real-time monitoring, and automated feedback systems allows tube lasers to adjust parameters on the fly, ensuring optimal performance even in dynamic operating environments.

7. Safety, Maintenance, and Operation Guidelines

7.1 Safety Standards for Operation

Operating high-power laser systems necessitates strict adherence to safety standards (such as IEC 60825). Protective eyewear, proper shielding, and interlock systems are essential for safeguarding operators.

7.2 Regular Maintenance and Fault Diagnosis

Routine checks on output power, temperature, and beam quality help maintain performance. Regular cleaning of optical components and systematic diagnostics are key to minimizing downtime.

7.3 Troubleshooting and Emergency Procedures

Establishing clear emergency shutdown procedures and modular troubleshooting steps ensures rapid fault isolation and repair, minimizing risks and operational interruptions.

8. Market Status and Future Outlook

8.1 Market Scale and Competitive Landscape

The global tube laser market is experiencing steady growth, driven by increasing demand for high-precision manufacturing and advanced research applications. Leading manufacturers are continuously innovating to maintain competitive advantages.

8.2 Policy Environment and Standardization

Government initiatives and stringent safety regulations play a pivotal role in shaping the tube laser industry. Standardized certification processes ensure product quality and reliability, fostering broader market acceptance.

8.3 Future Trends and Technical Challenges

Looking ahead, tube lasers are expected to evolve towards even greater efficiency, smart control integration, and cross-disciplinary applications (such as quantum communications and biophotonics). Key challenges include managing higher power outputs, further improving thermal management, and reducing system complexity.

9. Conclusion and Outlook

9.1 Summary of Key Points

This guide has provided an in-depth exploration of tube lasers—from their fundamental operating principles and technical advantages to their diverse application fields. We examined how tube lasers compare with other laser types and highlighted their role in precision industrial processes, research, medical applications, and communication systems.

9.2 Future Development Recommendations

- Research & Innovation: Continued advancement in materials and laser design will enhance efficiency and longevity.

- Market Expansion: Standardization and cross-industry collaboration will drive broader adoption of tube lasers.

- Safety & Training: Ongoing emphasis on safety protocols and operator training remains critical for reliable and secure operation.

9.3 References and Further Reading

For a deeper understanding, readers are encouraged to consult specialized journals, technical white papers, and international standards on laser technology.

10. Appendix

10.1 Glossary of Terms

- Stimulated Emission: The process by which an excited particle, when stimulated by an external photon, emits a new photon that matches the stimulating photon in phase, frequency, and direction.

- Resonant Cavity: An optical cavity formed by reflective surfaces, essential for amplifying light within a laser system.

- TEM00 Mode: The fundamental transverse mode of a laser, characterized by a Gaussian beam profile with high beam quality and uniform intensity distribution.