Revolutionizing Precision Manufacturing

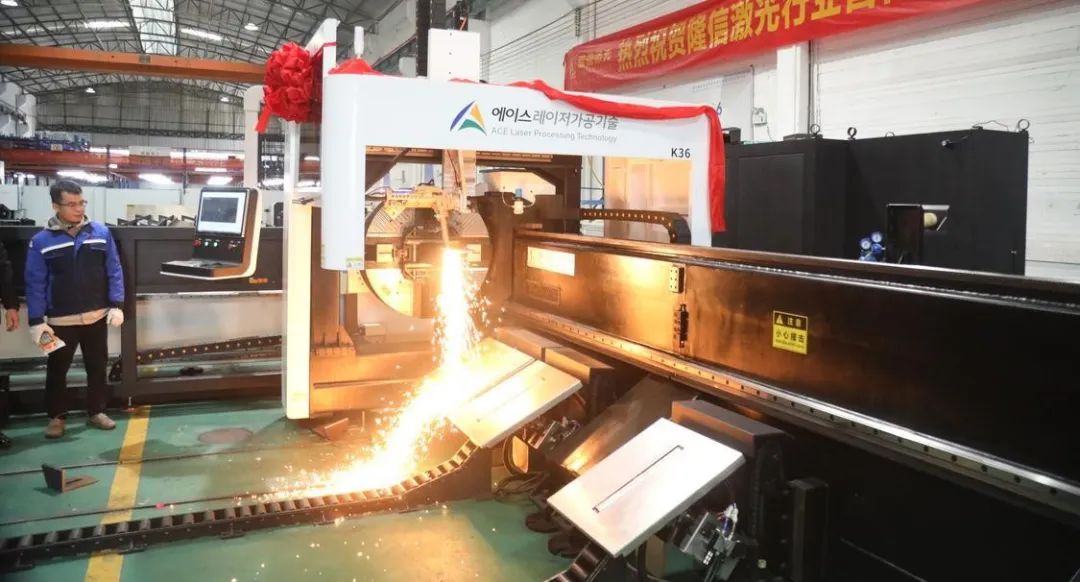

In the realm of advanced manufacturing, precision, efficiency, and diverse material processing technologies play a crucial role in innovation and meeting market demands. The introduction of the K36 3D 5-Axis Heavy-Duty Laser Pipe Cutter by LONXIN Laser represents a pinnacle in global CNC machine tool technology.

A Giant Leap in Custom Machinery Development

On December 19th, the town of Danzao witnessed a groundbreaking achievement as LONXIN Laser unveiled the industry’s first heavy-duty and ultra-long K36 3D 5-Axis Laser Pipe Cutter. This technological marvel, with a length of 46 meters, significantly surpasses the conventional size of 12 meters, showcasing LONXIN Laser’s commitment to overcoming technical challenges in the field of custom machinery development.

We successfully delivered the equipment to ACE E&T in South Korea’s modern shipbuilding industry. This marks that Longxin Laser has reached a new level in the field of customized machine research and development, demonstrating its strong R&D and production strength.

Mr. Xia Guozhang, Chairman of Longxin Laser, Mr. 김대환, a representative of ACE E&T in Korea’s modern shipbuilding industry, Minister Liu Taicheng (transliteration), and Mr. Guo Jing, Assistant to the Mayor of Science and Technology of Danzao Town, attended the delivery ceremony.

ACE E&T, a globally recognised shipbuilder in the Hyundai shipbuilding industry in Korea, has always been committed to improving productivity and product quality. However, as their business continued to expand, conventional cutting methods could no longer meet their needs for high precision and efficiency.

Against this background, Modern Shipbuilding started to look for advanced tube cutting equipment that could improve productivity and reduce costs while ensuring cutting accuracy. After in-depth market research and comparison, they chose Lonxin Laser, which has rich professional experience in the field of tube processing, to customise this super heavy and long laser tube cutting machine.

Empowering Industries with Smart Solutions

The cutting-edge machine offers customers an intelligent and efficient solution for heavy-duty pipe cutting. With customizable options for different lengths of pipes and equipped with a smart dynamic loading and unloading system, the K36 is poised to become a pioneering force in the manufacturing industry.

Technological Advancements Redefining Efficiency

As the industry’s longest 3D 5-axis heavy-duty laser cutting machine, LX-K36 has length of 46 metres. The conventional size is generally 12 metres long. Every step of Longxin’s laser research and development and transcendence is a technical difficulty.

The chairman of Longxin laser Xia Guozhang said: K36 3D 5-axis heavy-duty laser tube cutting machine can provide customers with a set of intelligent and efficient in one of the heavy tube cutting solutions, according to the different lengths of the pipe optional, equipped with intelligent follow the loading and unloading system, to meet the needs of different lengths and types of pipe loading and unloading will become a leading work of the manufacturing industry.

The product adopts 3 chucks clamping design, which effectively solves the pain point of difficult processing of heavy and long pipes, so as to improve the precision, stable support, efficient cutting, and the maximum load capacity of single pipe is up to 1 tonne weight. At the same time, it can also greatly reduce the waste of pipe raw materials, reduce costs and increase efficiency, and bring significant economic benefits for the enterprise.

LONXIN Laser’s Trailblazing Journey in Intelligent Equipment

Longxin Laser has evolved into the most diverse manufacturer of laser tube cutting equipment in China. With a product range spanning over 30 categories, their equipment finds applications in various industries globally, serving over 5,000 renowned enterprises such as Midea, Liansu, and Aima Automotive.

Global Presence, Local Impact

With a production facility in Suzhou, Jiangsu, and subsidiaries in Turkey, South Korea, Vietnam, and Brazil, LONXIN Laser has achieved the highest shipment and category volumes of laser pipe cutting machines in the industry nationwide for 2023. The company holds more than 140 independent research and development patents and earned recognition as a national high-tech enterprise.

Future Outlook: Pioneering Technological Advancements

Looking ahead, LONXIN Laser remains poised for innovation, with plans to intensify research and development efforts. The company is committed to maintaining an average annual performance growth rate of over 70%, leveraging its technological prowess to propel the flexibility, efficiency, and high-end capabilities of China’s manufacturing industry.