In the realm of metal fabrication, precision and efficiency are paramount. Manufacturers constantly seek innovative technologies to enhance their processes and meet the demands of modern industries. Among these advancements,

fiber laser pipe cutting machines have emerged as game-changers, offering unmatched precision, versatility, and speed in cutting various types of pipes and tubes. In this article, we delve into the capabilities and advantages of fiber laser pipe cutting machines, exploring how they are transforming the landscape of metal fabrication.

Unmatched Precision:

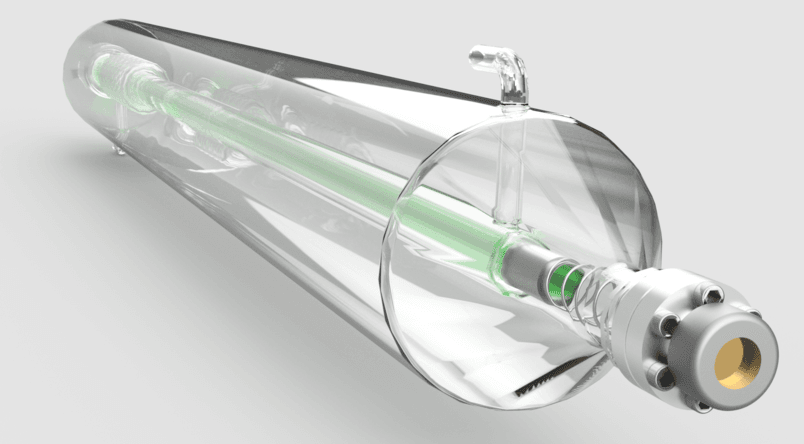

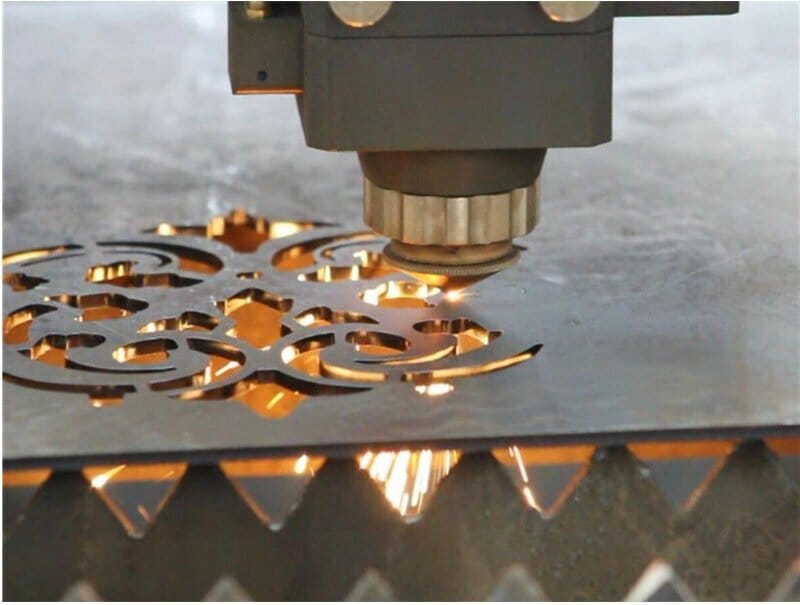

Fiber laser pipe cutting machines utilize advanced laser technology to achieve unparalleled precision in cutting pipes and tubes. With high-power fiber lasers and precision motion control systems, these machines can produce intricate cuts with tolerances measured in fractions of a millimeter. Whether cutting thin-walled tubes or thick pipes, fiber laser technology ensures clean, precise edges without distortion or burrs, meeting the strictest quality standards demanded by industries such as aerospace, automotive, and medical device manufacturing.

Versatility in Material Compatibility:

One of the key advantages of fiber laser pipe cutting machines is their ability to process a wide range of materials with ease. From stainless steel and carbon steel to aluminum, brass, and copper, fiber lasers can effortlessly cut through various metals, accommodating diverse fabrication needs. Moreover, fiber lasers excel in cutting reflective materials that traditionally posed challenges for other cutting methods, making them ideal for applications requiring high-quality finishes and intricate designs.

Enhanced Productivity:

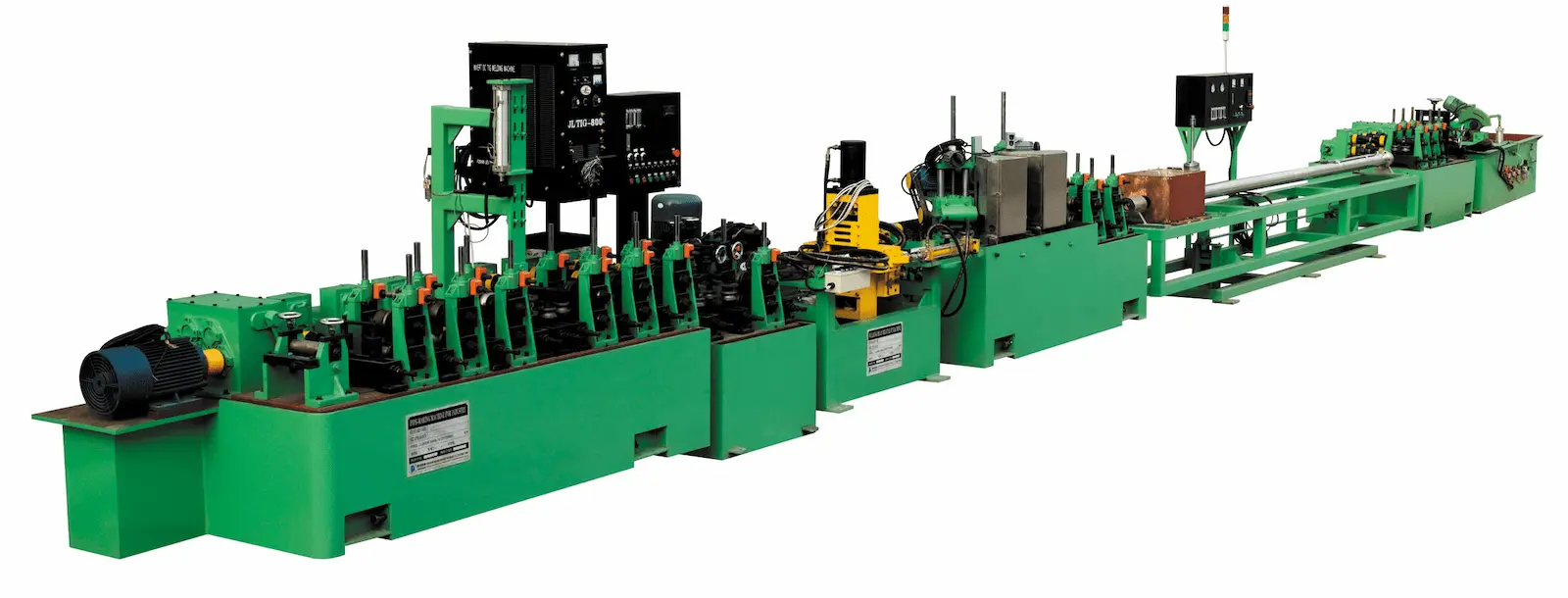

In addition to precision and material versatility, fiber laser pipe cutting machines offer remarkable speed and efficiency in metal fabrication. With rapid acceleration and cutting speeds, these machines can significantly reduce production cycle times, enabling manufacturers to meet tight deadlines and scale their operations effectively. Furthermore, fiber lasers require minimal setup and tooling changes, allowing for seamless transitions between different cutting tasks and maximizing uptime in busy production environments.

Cost-Effectiveness and Sustainability:

While the initial investment in fiber laser pipe cutting machines may seem significant, their long-term cost-effectiveness cannot be overstated. Compared to traditional cutting methods such as plasma or oxy-fuel cutting, fiber lasers consume less energy, produce minimal waste, and require fewer consumables, resulting in lower operating costs and higher profitability over time. Additionally, the precision of fiber laser cutting minimizes material waste, further reducing material costs and environmental impact, aligning with sustainable manufacturing practices.

Applications Across Industries:

The versatility and efficiency of fiber laser pipe cutting machines make them indispensable tools across a wide range of industries. From fabricating structural components for buildings and bridges to manufacturing intricate parts for machinery and equipment, fiber lasers play a crucial role in various sectors. Whether cutting round, square, or rectangular tubes, fiber laser pipe cutting machines enable manufacturers to achieve complex geometries, bevels, and miters with unmatched speed and precision, opening new possibilities for innovation and customization.

Conclusion:

In conclusion, fiber laser pipe cutting machines represent a significant advancement in metal fabrication technology, offering unparalleled precision, versatility, and efficiency. With their ability to process a wide range of materials, achieve intricate cuts, and enhance productivity, fiber lasers are driving innovation and competitiveness in industries around the globe. As manufacturers continue to embrace these cutting-edge technologies, the future of metal fabrication looks brighter than ever, propelled by the power of fiber laser pipe cutting machines.