Станки для лазерной резки труб и станки для плазменной резки труб обычно используются для изготовления металла, но между этими двумя технологиями резки труб есть ключевые различия. Давайте подробнее рассмотрим, как работает лазерная и плазменная резка труб, и сравним их возможности, преимущества и пригодность для различных применений.

Принцип резки

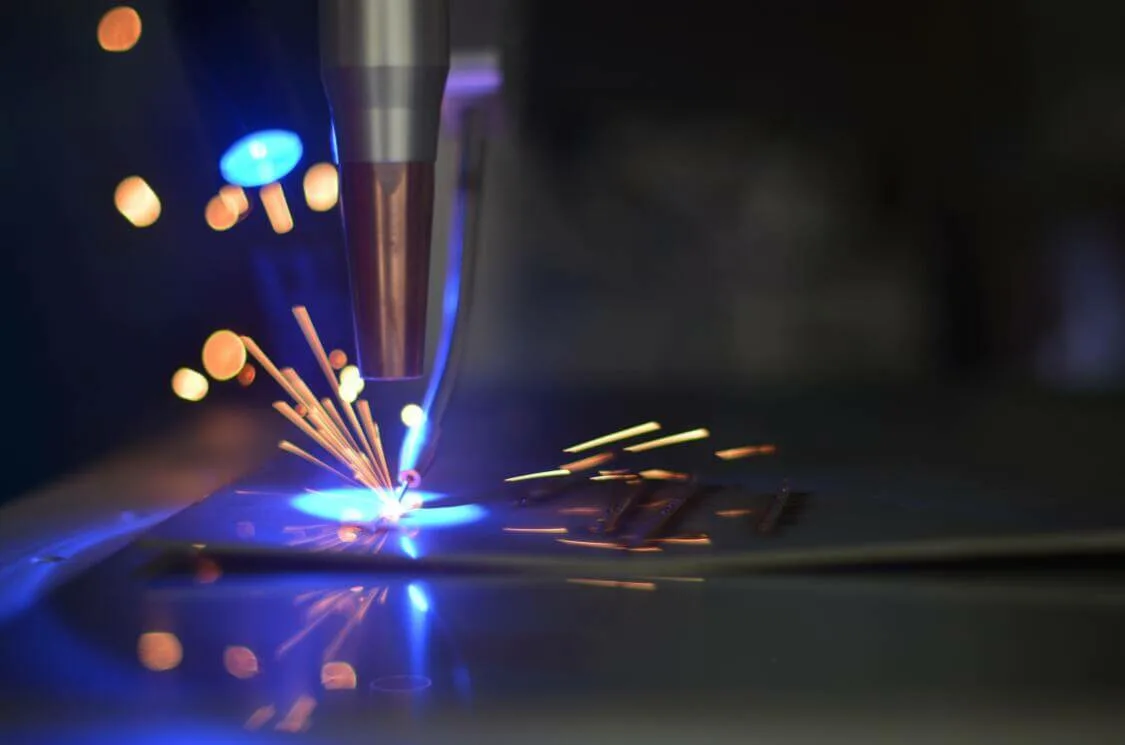

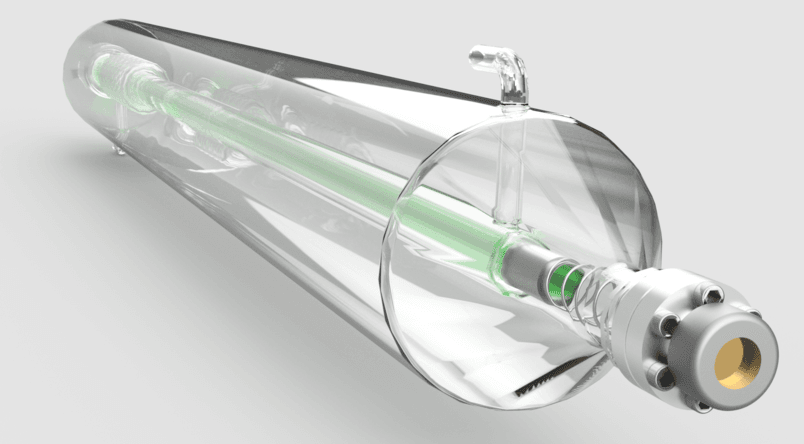

Основное различие заключается в используемых принципах резки. В станке для лазерной резки труб используется мощный лазерный луч, который точно фокусируется на поверхности металла. Интенсивное тепло, исходящее от лазера, мгновенно расплавляет или испаряет металл вдоль определенной траектории резания.

Плазменная резка труб работает немного по-другому. В этом процессе плазменная горелка направляет высокоскоростной поток ионизированного газа, известного как плазма, к металлической заготовке. Когда плазма вступает в контакт с трубкой, она выделяет огромное количество тепла, расплавляя материал. Затем перегретые газы выдуваются сжатым воздухом, оставляя чистую режущую кромку.

Точность и качество Резки

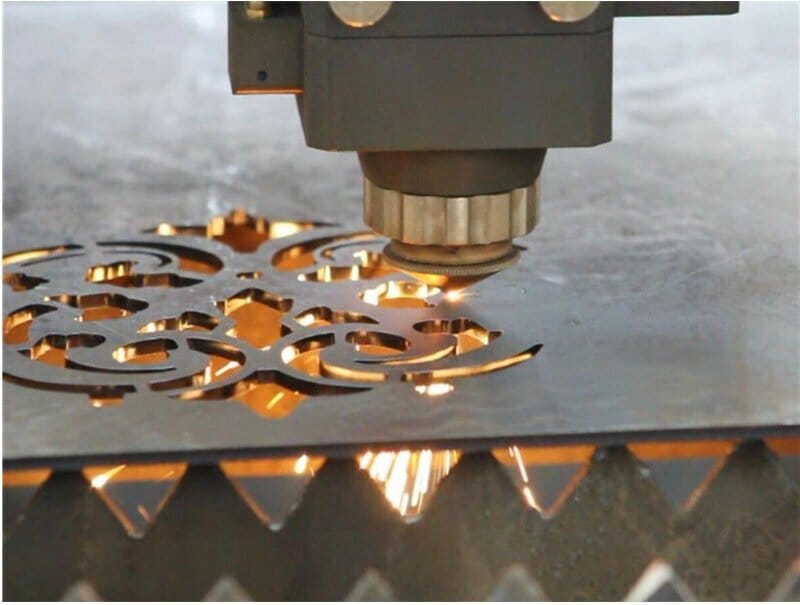

The cutting accuracy and quality achieved with each method can vary considerably. Laser tube cutting is renowned for its extremely high precision, producing cuts that are very precise with almost no dross or burrs on the edges. Tolerances can be held within a few thousandths of an inch.

On the other hand, plasma cutting tends to be somewhat less accurate due to the higher temperatures involved. The heat-affected zone is typically larger, resulting in rougher edges that may need further finishing like grinding. Slot and hole geometries are also not as well-defined as with laser cutting.

Скорость Резки

When it comes to cutting speed, laser machines can cut faster than plasma for many common tubular materials and thicknesses up to a certain point. However, beyond a thickness of around 1/2 inch, plasma cutting becomes faster since it can process large amounts of material quicker than a laser.

For very thick section tube cutting jobs over 1 inch thick, plasma is normally the faster technique. Its higher cutting speeds make it more suitable for larger production runs involving heavy-duty materials.

Scope of Application

Both laser and plasma cutting can handle a wide variety of metallic workpieces. However, laser cutting has a slight edge in application versatility. It can cut delicate or heat-sensitive materials like stainless steel, aluminum, and copper with greater precision and minimal heat input.

On the other hand, plasma is more limited to electrically conductive metals where the current can be efficiently transferred, like carbon steel, aluminum, and some alloys. Non-ferrous metals may require special gases and torches for plasma cutting.

Затраты на Оборудование

The upfront capital expenditures required for laser and plasma tube cutters differ significantly. On average, an industrial laser cutting machine represents a higher initial financial investment compared to a plasma system.

This is due to factors like the sophisticated optics, precision mechanics, and high-powered laser source involved. Plasma cutting equipment yields short payback periods through relatively low purchase prices and operational costs. Maintenance requirements are also generally less for plasma technology over the long run.

Energy Efficiency

From the perspective of energy efficiency during operation, plasma tube cutting has a clear upper hand. Despite plasma’s higher cutting temperatures, it consumes less power per cut compared to laser cutting where a portion of the laser energy is lost as heat.

This makes plasma tube cutting slightly more economical for mass production scenarios involving extensive cutting cycles. However, laser cutting is catching up with new fibre laser sources delivering improved wall plug efficiency.

Process Emissions

Regarding exhaust emissions generated, laser tube cutting produces cleaner fumes than plasma cutting. The laser’s focused heat results in more contained vapors and smoke compared to plasma’s open arc. Most laser operators can forgo expensive exhaust extraction systems as emissions dissipate rapidly.

Conversely, plasma cutting requires forced ventilation and possibly a fume extractor to safely remove noxious gasses from the cutting area. Special precautions need to be taken for some materials like steel with its potential for generating hazardous smoke particles.

Choosing the Right Technology

In summary, both laser and plasma cutting have proven track records when it comes to tubular fabrication needs. The choice often depends on project-specific factors like:

- Required tolerances and surface finish

- Production volumes and throughput needs

- Tube material type and thickness

- Part complexity (holes, slots, contours)

- Available capital budget

- Energy usage and emissions priorities

Laser cutting generally excels for intricate designs, finer details, and a range of non-ferrous metals. Plasma is better suited to bulky jobs demanding high cutting speeds in carbon steels. Both technologies harmoniously coexist across manufacturing industries serving complementary roles. With advances ongoing, each offers valuable tube cutting solutions.

Through informed comparisons of their key capabilities, advantages and suitability for different applications, tube fabricators can select the optimal technology that best meets their productivity and quality objectives. Attention should also be given to factors like total cost of ownership over the equipment life cycles. An integrated perspective helps maximize benefits from laser or plasma tube cutting systems.