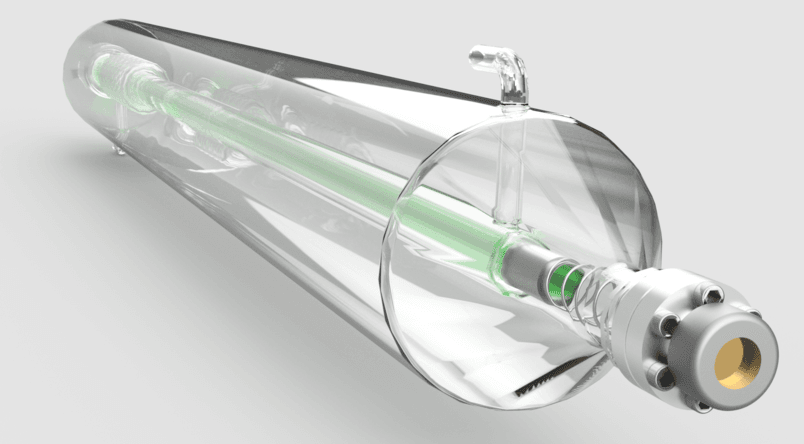

Лазерная сварка - это революционный метод сварки, в котором используется высокоэнергетический лазерный луч для расплавления металлических поверхностей. Этот передовой метод обладает рядом преимуществ по сравнению с традиционными методами сварки, что делает его все более популярным в различных отраслях промышленности.

Лазерные сварочные аппараты use a tightly focused laser beam to heat and melt the metal, allowing for precise and controlled welding. The process is characterized by a high aspect ratio, small weld width, minimal heat-affected zone, and fast welding speed. Additionally, laser welding produces smooth and beautiful welds, often eliminating the need for post-welding treatment or additional processing.

Вот некоторые отрасли промышленности, которые подходят для технологии лазерной сварки:

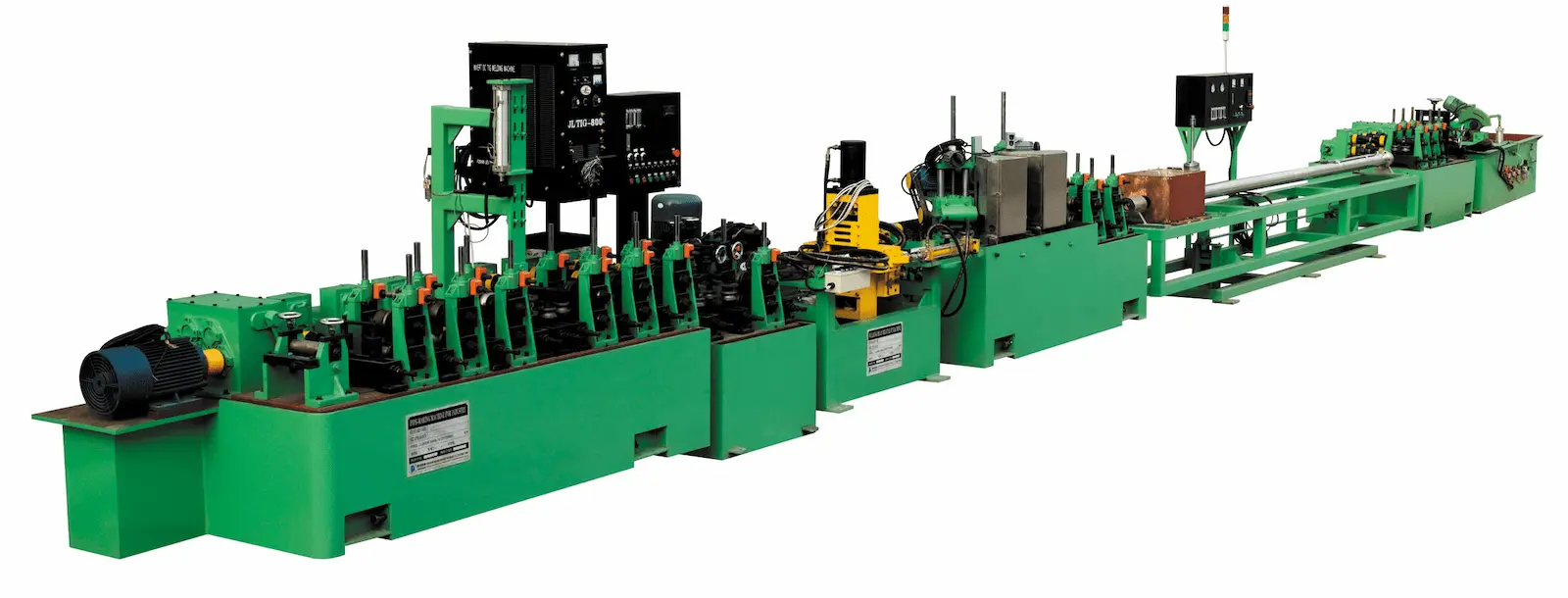

Sanitary Ware Industry

Laser welding is extensively used for welding water pipe joints, reducers, tees, valves, and shower components, taking advantage of the precise control and high-quality results.

Eyewear Industry

Индустрия очков полагается на лазерную сварку для точного соединения нержавеющей стали, титановых сплавов и других материалов, используемых в пряжках и внешней оправе очков.

Hardware Industry

Лазерная сварка применяется для сварки рабочих колес, чайников, ручек и других сложных штамповок и отливок в скобяной промышленности.

Automotive Industry

Применение лазерной сварки в автомобилестроении включает, среди прочего, прокладки цилиндров двигателя, сварку гидравлических толкателей, сварку свечей зажигания и сварку фильтров.

Medical Industry

Медицинская промышленность использует лазерную сварку для сварки медицинских приборов, уплотнений из нержавеющей стали и конструктивных элементов различного медицинского оборудования.

Electronic Industry

Laser welding is widely used in the electronic industry for sealing and breaking welding of solid-state relays, welding of connectors, and the welding of metal shells and structural parts for devices like mobile phones and MP3 players.

Aerospace Industry

The aerospace industry widely uses laser welding for its precision, reliability, and ability to handle specialized materials like aluminum and titanium in aircraft construction.

Shipbuilding Industry

Laser welding is adopted in shipbuilding for its efficiency and suitability in handling thick steel plates and complex ship structures, enabling faster build times and improved weld quality.

Energy and Power Generation

Laser welding is utilized in energy and power generation for fabricating high-performance components like turbine blades, heat exchangers, and pressure vessels, where reliability and safety are crucial.

Robotics and Automation

Laser welding systems can be easily integrated into automated manufacturing processes in the robotics and automation industries, enabling precise, repeatable, and high-speed welding of delicate components.

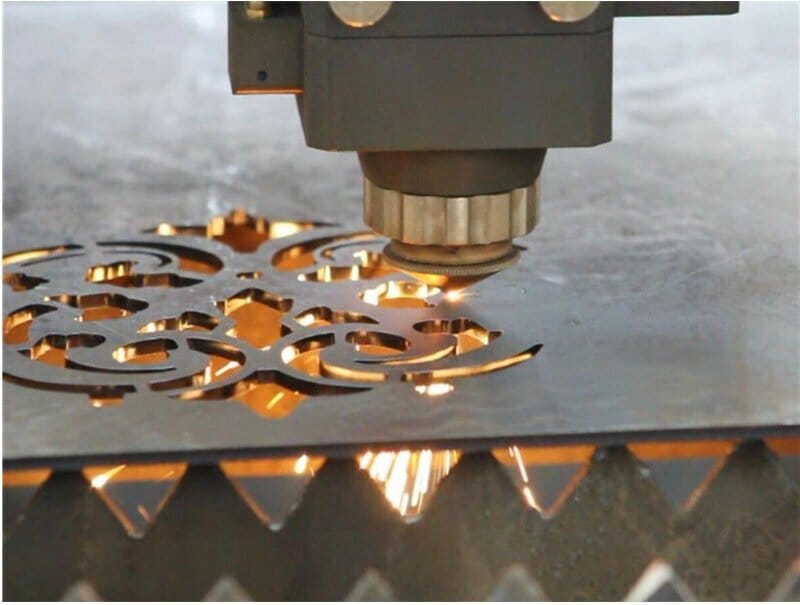

The advantages of laser welding, such as its concentrated energy, lack of pollution, small welding spots, wide range of weldable materials, high efficiency, and high-speed welding, make it an attractive choice for industries with specific requirements. Products that require precise welds, highly automated processes, and welding in unique conditions or hard-to-reach areas are particularly well-suited for laser welding technology.

As laser welding continues to evolve and become more accessible, its applications are expected to expand further, transforming the way industries approach their welding needs and ensure the quality and efficiency of their manufacturing processes.