Customer Overview

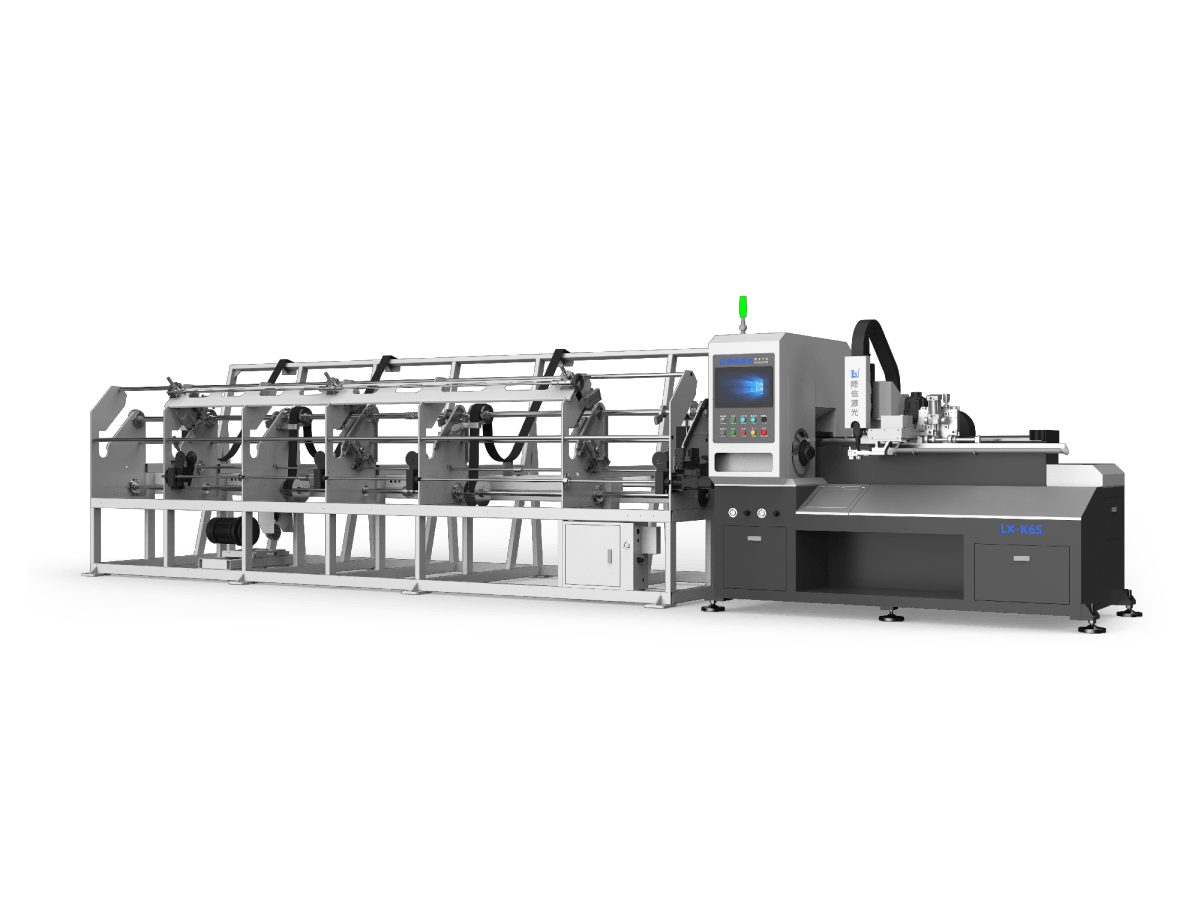

A Vietnamese furniture manufacturer has implemented four K6S economical CNC laser tube cutting systems in their production facility. The company specializes in modern furniture production, processing rectangular tubes of 40*20mm and square tubes of 25*25mm for various furniture components.

Equipment Features & Benefits

The K6S laser tube cutter was selected for its practical features:

- High-strength bed construction ensuring stability during high-speed operation

- Efficient short tail material processing (≥40mm), minimizing material waste

- Customer-oriented design with independent R&D in both hardware and software

- Flexible system supporting customization based on production needs

- Excellent cost-performance ratio with fully automatic production capabilities

Production Setup

Equipment Configuration

- Four K6S laser cutting machines operating in parallel

- Each machine equipped with customized features for furniture production

- Flexible automation features for efficient material handling

Material Processing

- Main materials:

- 40*20mm rectangular tubes for table and cabinet frames

- 25*25mm square tubes for chair components

- Automated processing with minimal operator intervention

- Short tail capability efficiently handling 40mm and longer materials

Production Operation

The facility maximizes the K6S systems’ capabilities through strategic deployment:

Workflow Organization

- Two machines dedicated to rectangular tube processing (40*20mm)

- Two machines handling square tube cutting (25*25mm)

- Flexible workload distribution based on production demands

Operational Advantages

The multi-machine K6S setup delivers several key benefits:

- Cost-effective automated production

- High-speed, stable processing

- Efficient material utilization with short tail capability

- Easy adaptation to varying production requirements

- Reliable performance supported by core technology

Production Results

The implementation of four K6S machines has enhanced their furniture manufacturing operations through:

Efficiency Improvements

- Increased production throughput with stable, high-speed processing

- Reduced material waste through efficient short tail handling

- Lower operating costs with automated production

Manufacturing Flexibility

- Easy adjustment to different product specifications

- Quick response to urgent orders

- Balanced production load across machines

- Minimal downtime during maintenance

Application Scope

The facility utilizes the K6S systems’ versatility for various furniture components:

- Table and desk frames

- Chair structures

- Cabinet frameworks

- Display unit components

- Custom furniture pieces