Client Overview

- Company: TOPSUN

- Industry: Telescopic Bracket Manufacturing

- Location: Vietnam

Challenge

TOPSUN, a leading manufacturer of telescopic brackets in Vietnam, faced increasing demand for their products. They needed a solution to enhance their production efficiency, particularly in cutting galvanized round tubes with a diameter of 32mm, which are crucial components in their telescopic bracket assemblies.

Project Details

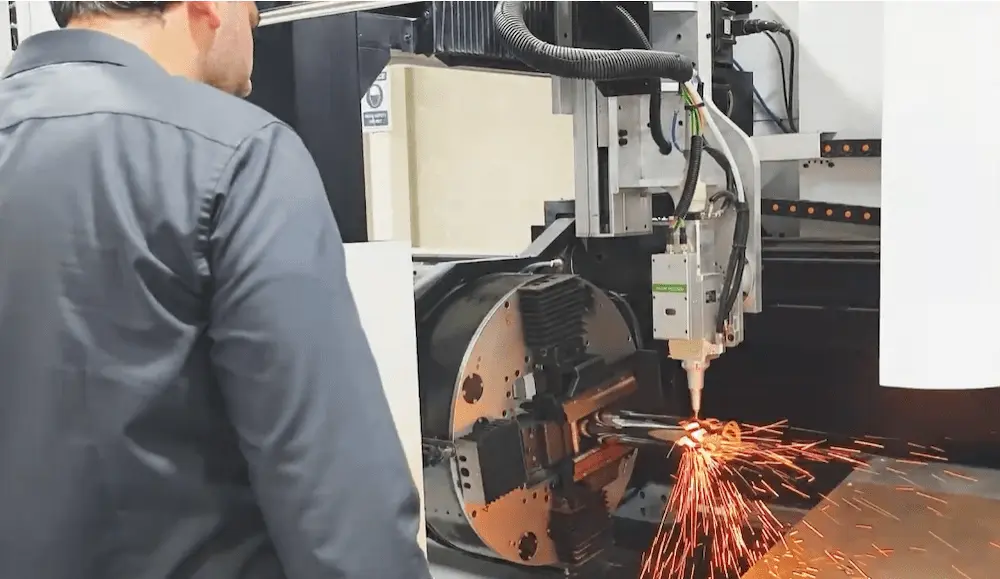

- Machine Model: LX-K16X Laser Tube Cutting Machine

- Material Processed: Galvanized Round Tubes, 32mm diameter

- Application: Production of telescopic brackets

Key Benefits

- Improved Cutting Precision: The LX-K16X delivers high-precision cuts on 32mm galvanized round tubes, essential for telescopic bracket manufacturing.

- Increased Efficiency: Advanced laser technology significantly speeds up the tube cutting process, boosting overall production capacity.

- Versatility: While primarily used for 32mm round tubes, the LX-K16X can handle various tube shapes and sizes, offering flexibility in production.

- User-Friendly Operation: The machine’s intuitive interface allows for easy operation and quick adaptation by TOPSUN’s staff.