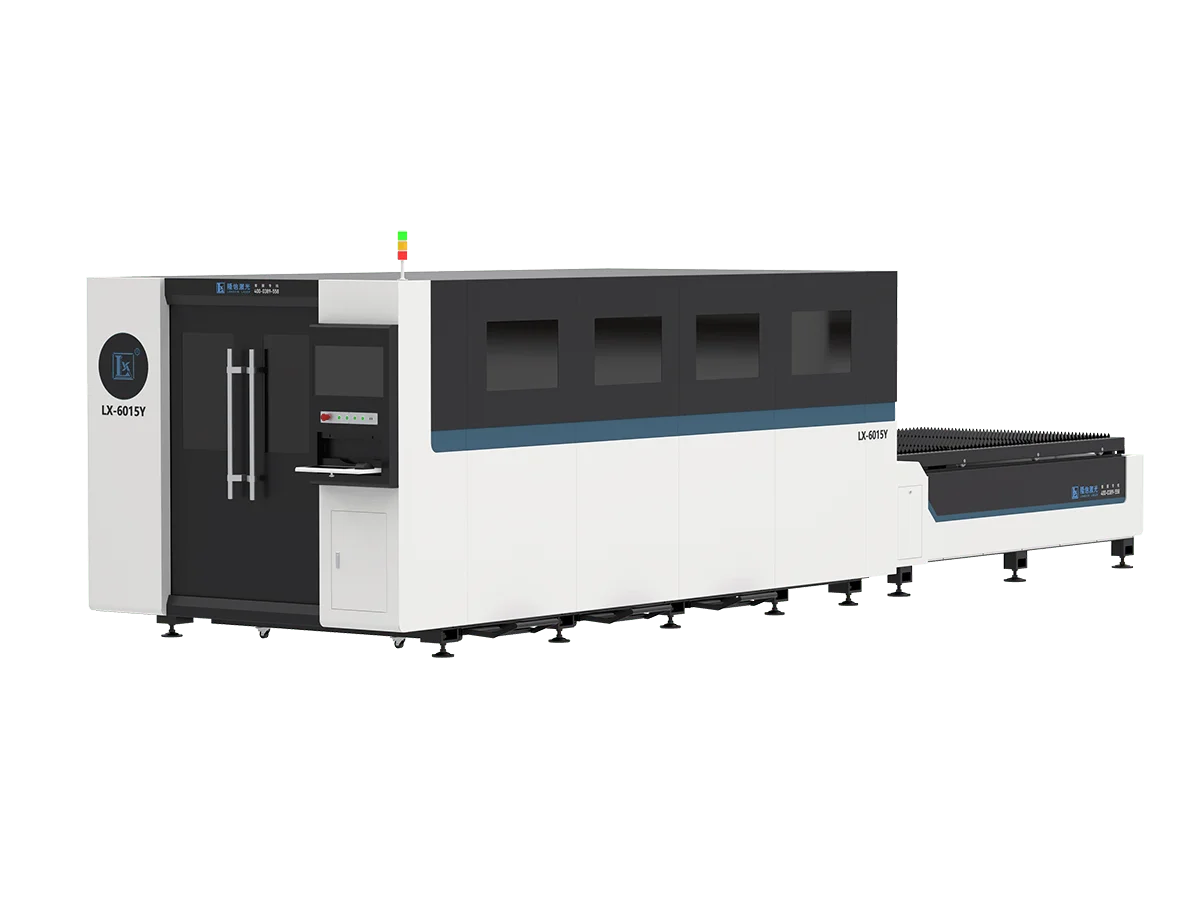

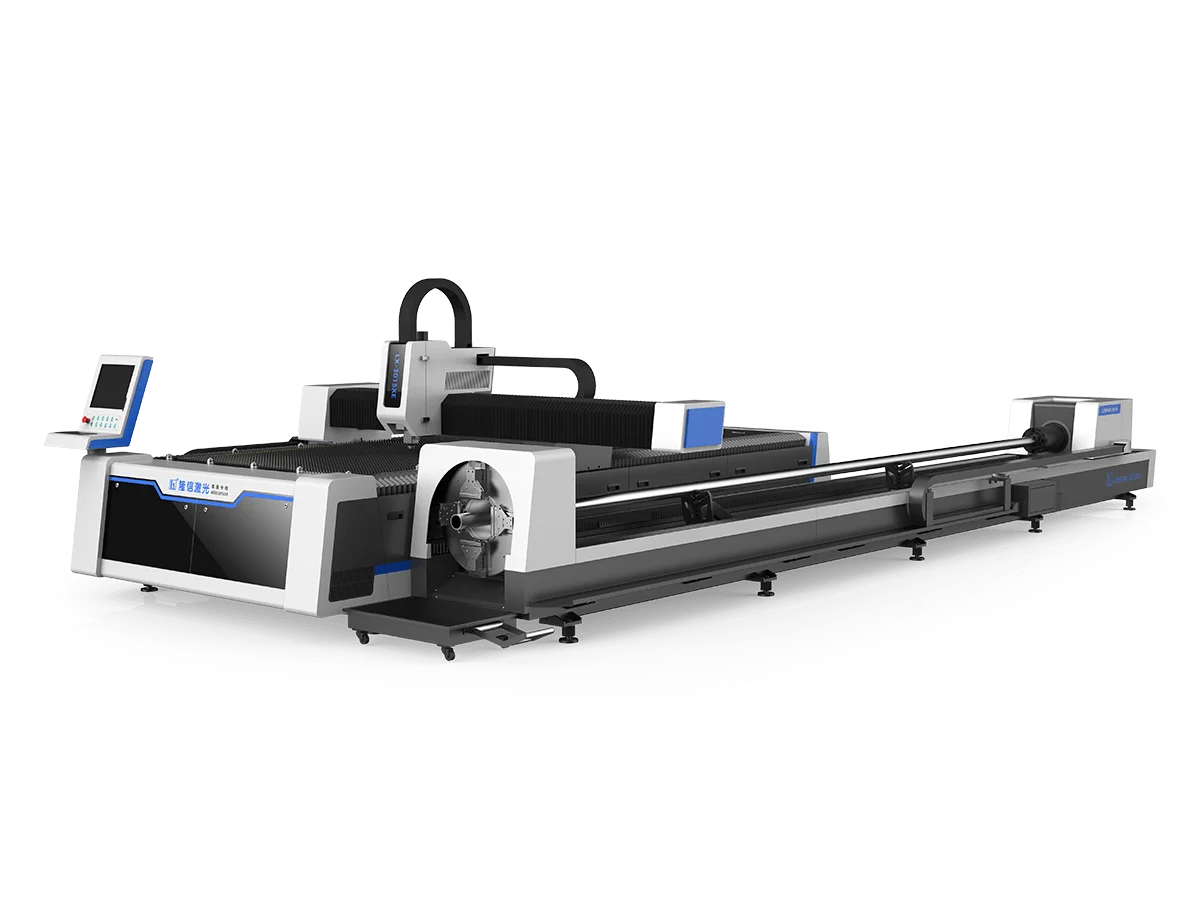

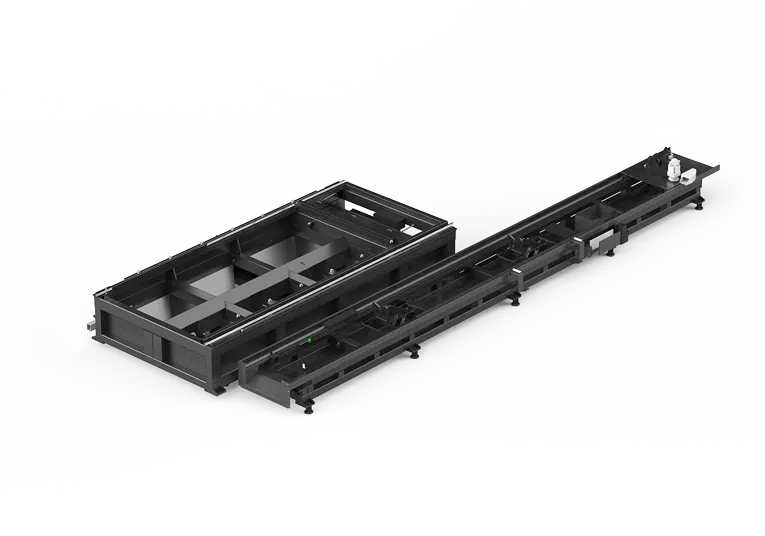

Sheet and tube laser cutting machine

LX-3015XE

Video

Technical Parameters

- Model:

- Laser power:

- Working sheet

- X-Axis Travel

- Y-Axis Travel

- Z-Axis Travel

- XY motion accuracy

- Repeat Position Angle

- Working speed

- Acceleration

- Power demand

- Machine weight

- Apparent size

HIGH RIGIDITY AND STABILITY BED

- The frame structure welded by high-quality steel plates, after professional large-scale welding, 24-hour thermal aging treatment, and precision machining of large-scale gantry milling machines.

- These designs And processing means to ensure that the machine tool has excellent shock resistance, high rigidity and stability.

INTEGRATED STEEL FILM CAST ALUMINUM BEAM

- Heavy-duty steel mold die-casting: high mold cost, long life, good fluidity of aluminum water, uniform density,

- Integrated steel film cast aluminum beams, precision machined, anti-corrosion, anti-oxidation, good toughness and ductility

- It is light in weight and can ensure high-speed movement during cutting, which can greatly increase the processing speed while meeting the processing accuracy.

HIGH-END CNC SYSTEM

- Adopting the most advanced Shanghai Fascut high-performance open-loop laser control system

- It has the characteristics of stability, reliability, convenient debugging, and production safety.

- With rich functions and excellent performance, it is one of the systems with the highest market share and is widely welcomed by users.

PARTITIONED DUST EXTRACTION

- Patented design, time-sharing, divisional, segmental dust extraction structure.

- The air volume of the pipeline is specially designed and tested by professional wind speed instruments

- It can achieve truly smoke-free and dust-free cutting in the cutting area.

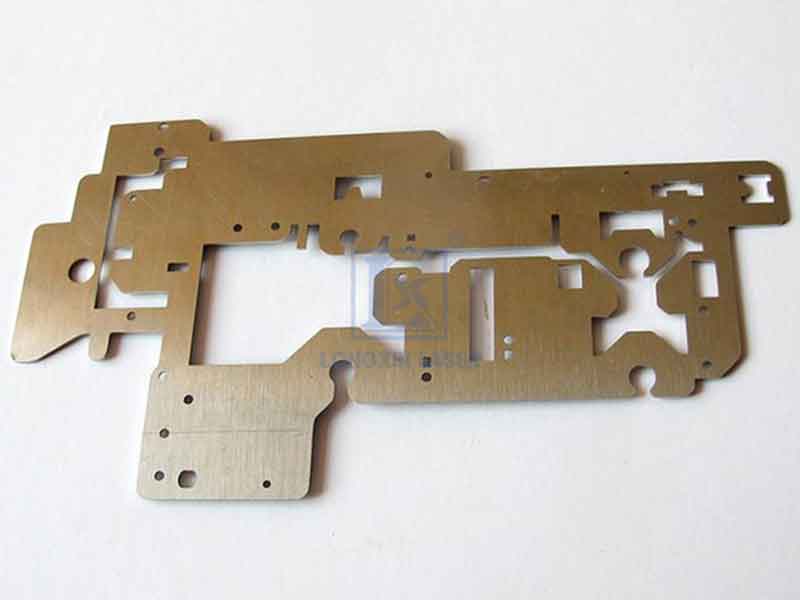

Cutting Samples

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Order Process for Laser Cutting Equipment

Related Products

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.