Introduction

In the highly competitive furniture manufacturing industry, efficiency and precision are paramount. This is especially true for our client, a leading furniture manufacturer in Vietnam specializing in bed frames. To enhance their production capabilities, they turned to our state-of-the-art LX-K9 tube laser cutter. This case study explores how our machine revolutionized their manufacturing process.

Customer Background

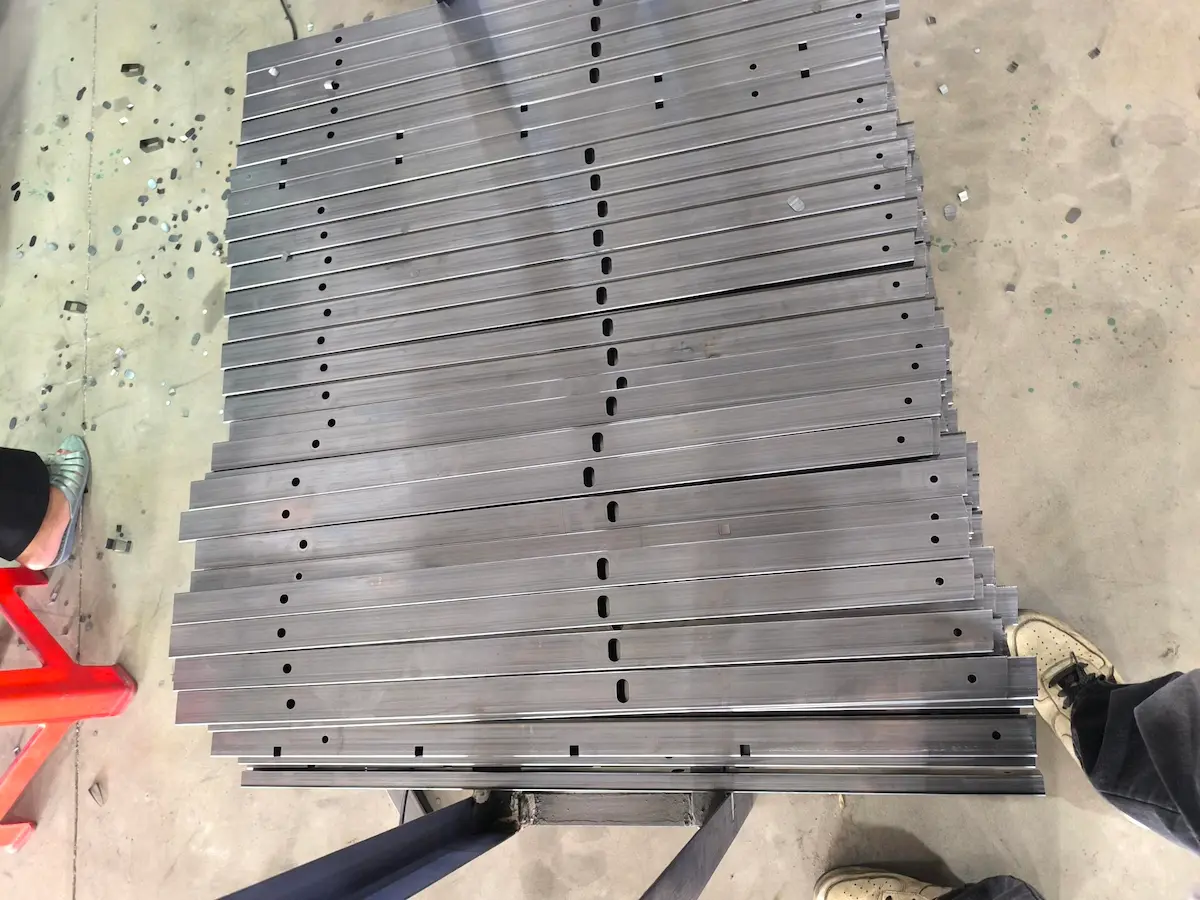

Our client is a prominent furniture manufacturer based in Vietnam, known for producing high-quality bed frames. They were facing significant challenges in cutting 20*40*0.7mm square tubes, which are a critical component of their products. The need for precise and efficient cutting methods led them to seek a reliable solution.

Challenges

Before implementing the LX-K9 tube laser cutter, the company struggled with several issues:

- Inefficiency in cutting processes, leading to delays in production.

- Inconsistencies in cut quality, resulting in material wastage.

- High operational costs due to manual labor and outdated equipment.

These challenges hindered their ability to meet growing market demands and maintain competitive pricing.

Solution

The introduction of the LX-K9 tube laser cutter provided a transformative solution. Key features of the LX-K9 that addressed the client’s needs include:

- High Precision: The LX-K9 ensures clean and accurate cuts for 20400.7mm square tubes, reducing material wastage.

- Efficiency: Automated cutting processes significantly cut down on production time and labor costs.

- Versatility: The machine’s capability to handle various tube sizes and shapes increased the client’s production flexibility.

Implementation Process

The implementation of the LX-K9 tube laser cutter was seamless:

- Installation: The installation team set up the machine at the client’s facility with minimal disruption to their ongoing operations.

- Training: Comprehensive training was provided to the client’s staff, ensuring they could operate the machine effectively.

- Optimization: The client’s production processes were optimized to fully leverage the LX-K9’s capabilities.

Results

The impact of the LX-K9 tube laser cutter on the client’s production was profound:

- Increased Productivity: Production speed increased by 35%, allowing the client to meet higher order volumes.

- Cost Savings: Operational costs were reduced by 25% due to lower labor requirements and decreased material wastage.

- Improved Quality: The precision of the LX-K9 resulted in consistently high-quality cuts, enhancing the overall quality of the bed frames.

Customer Feedback

The client was highly satisfied with the LX-K9 tube laser cutter. They noted significant improvements in their production efficiency and product quality. Here is their feedback:

“The LX-K9 has transformed our production process. The precision and speed of the machine have exceeded our expectations, allowing us to meet our deadlines with ease. The support and training provided by the Longxin Laser team were also outstanding.”

Conclusion

The LX-K9 tube laser cutter has proven to be an invaluable asset for our Vietnamese client, enabling them to overcome their production challenges and achieve remarkable results. If you are looking to enhance your manufacturing capabilities and boost productivity, contact us today to learn more about how the LX-K9 can benefit your operations.

Ready to revolutionize your production process? Contact us to learn more about the LX-K9 tube laser cutter and schedule a demonstration.