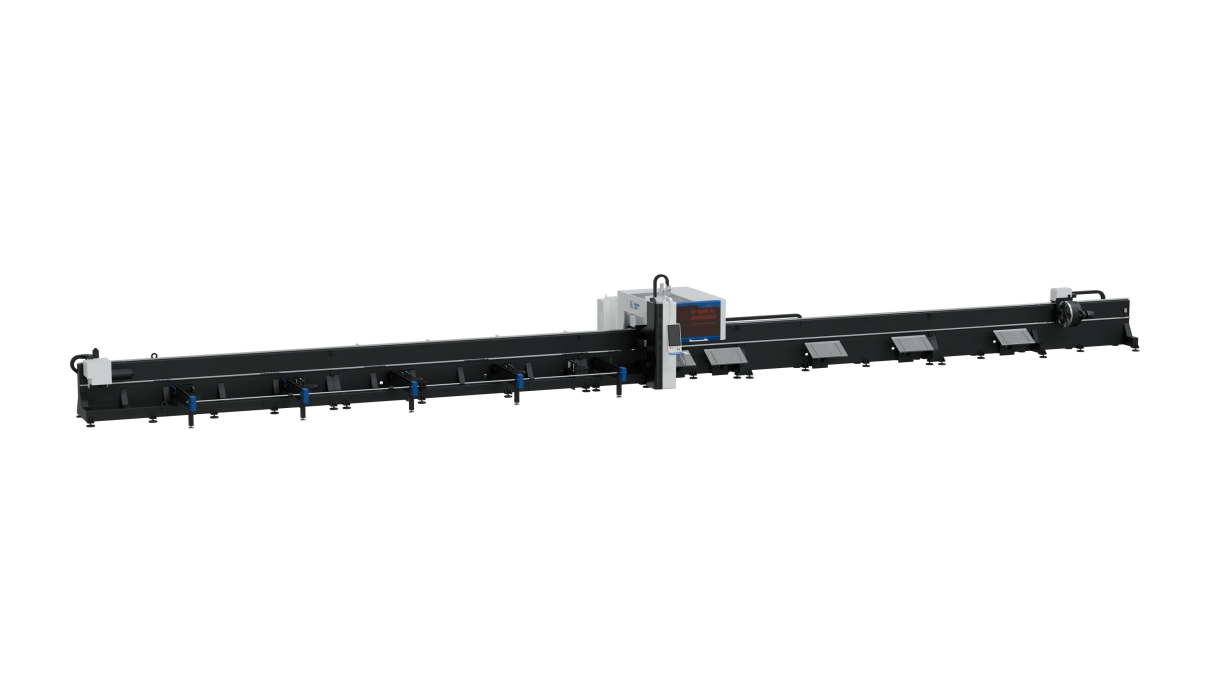

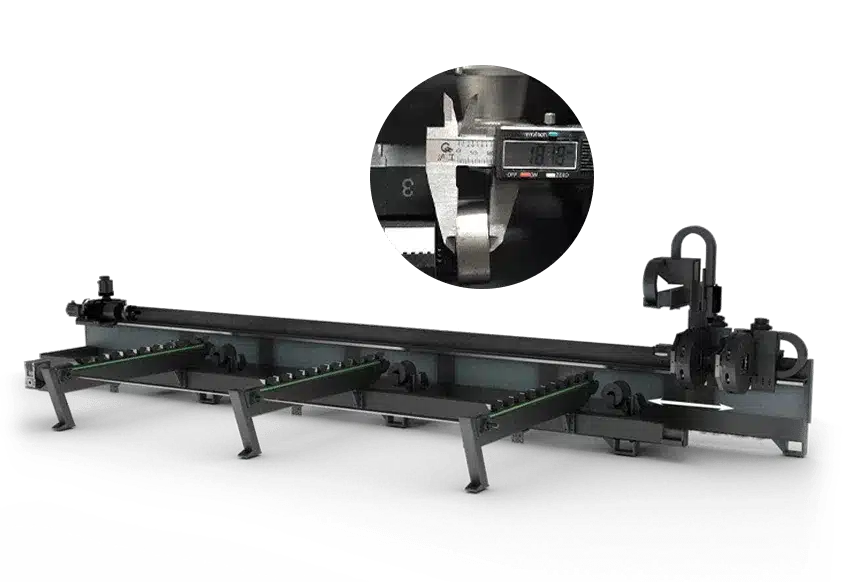

Ultra High-speed Small Pipe Laser Cutting Machine

LX-K9

- Ultra-short tail

- 1.5G acceleration, strong productivity

- FSCUT system and nesting software (optional)

- Cutting tube diameter range: round tube: ∅8-90mm square tube: □8*8-80*80mm

- Matching laser range: 1500-3000W

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

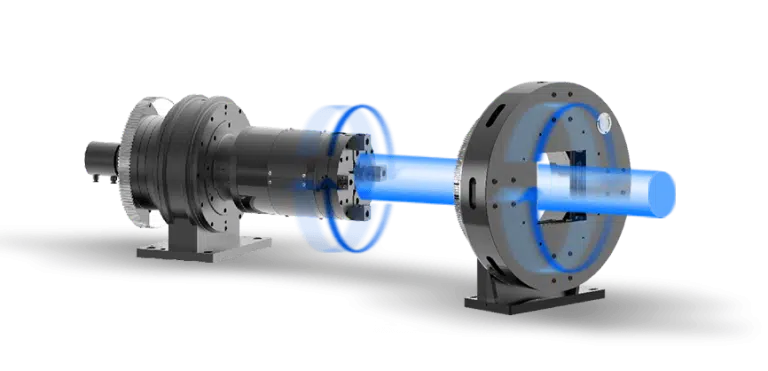

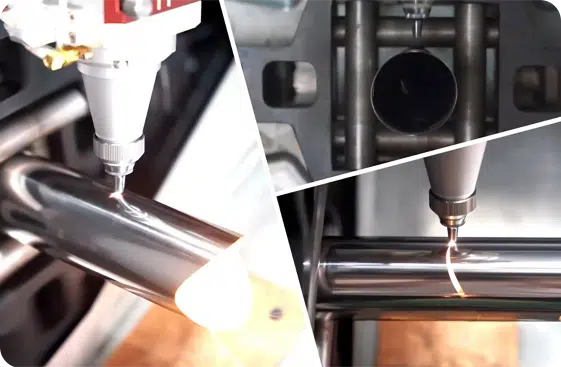

Versatile Pneumatic Chuck

Seamlessly transition between cutting requirements of various material and shapes without interruption.

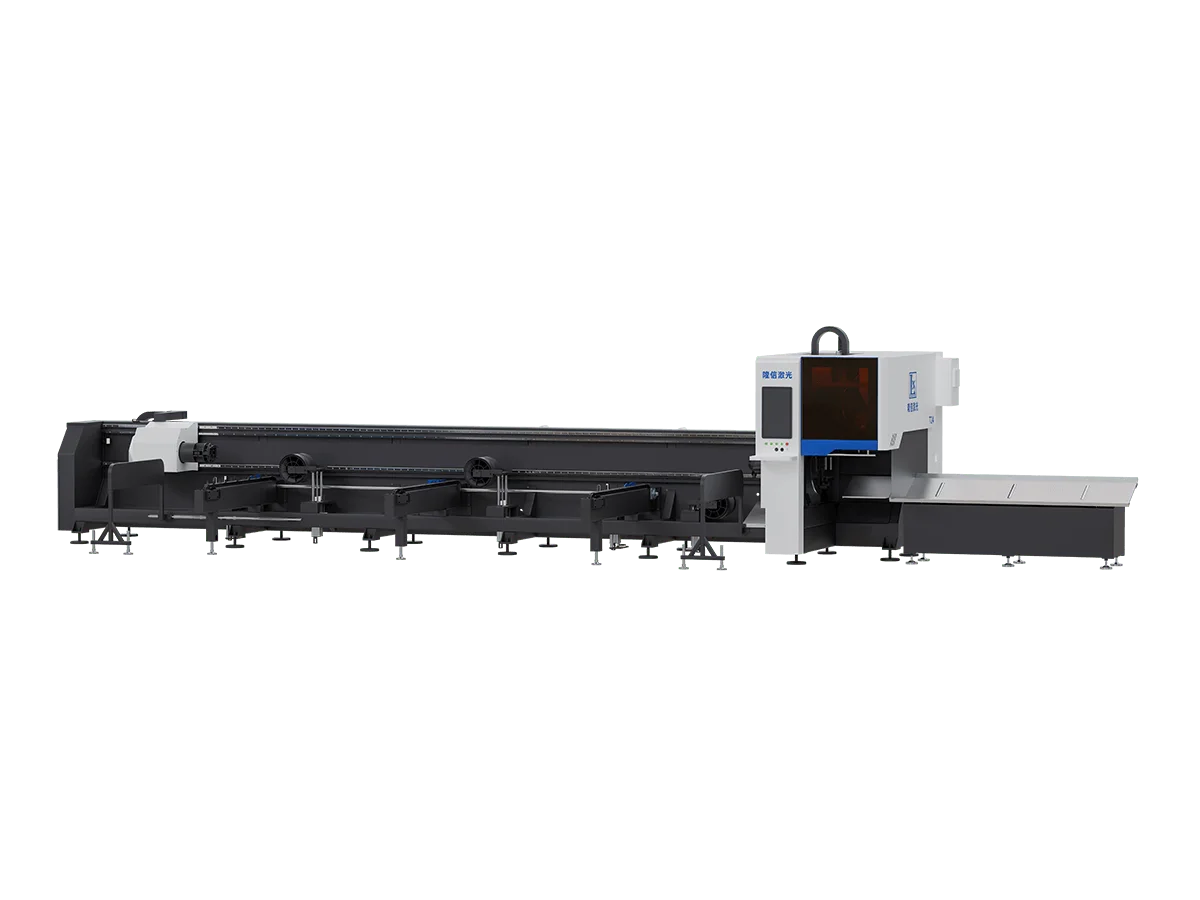

Minimized Waste, Maximized Savings

The unique mobile front chuck design allow the laser head to cut between the two chucks, reaching minimum tailing of 40 mm.

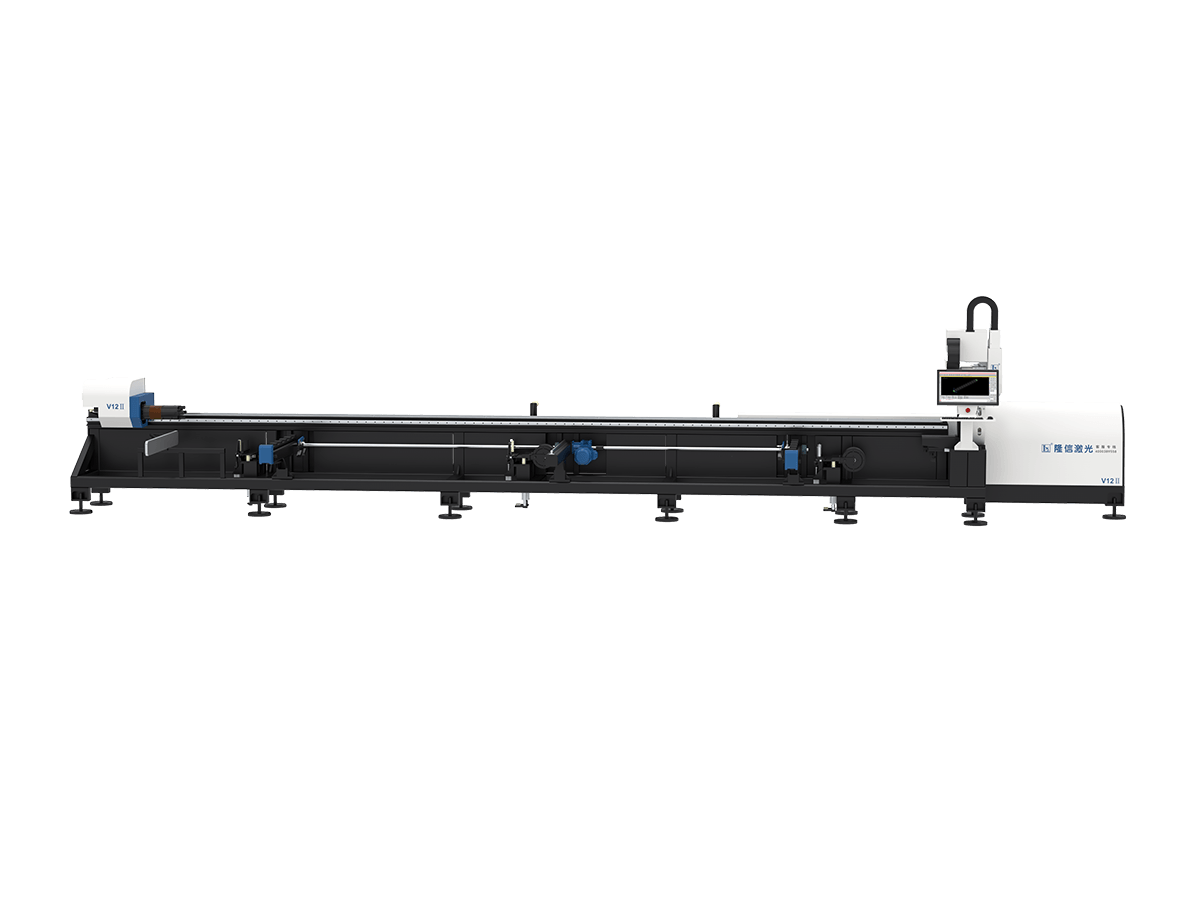

Economical but powerful

Unique design on key conponents and machine frame, reaching high cost-effective.

-拷贝.png.webp)

Specifically tailored for tiny tube cutting

The machanical design and the controller of this machine are with unique design for tiny tube cutting.

Cutting Samples

Success Stories