Introduction

In the competitive world of furniture manufacturing, efficiency and precision are paramount. This case study explores how a Russian bed frame manufacturer leveraged Longxin Laser’s advanced bed frame laser pipe laser cutting machine to build a fully automated pipe processing line — achieving 24/7 unmanned operation, reducing costs, and boosting productivity.

Production Challenges in the Bed Frame Industry

The client, a large-scale bed frame manufacturer based in Russia, faced increasing demand for cost-effective, high-precision production of metal bed frame structures. Seeking to automate labor-intensive processes like pipe cutting, hole punching, bending, and handling, they turned to Longxin Laser for a tailored solution that could integrate seamlessly into their existing production workflow.

How to Choose a Laser Pipe Cutting Machine for Bed Frame Manufacturing?

Metal bed frames typically use thin‑walled tubes—round, square and oval—with high precision and often require punching, bevel cuts and bending. When evaluating a bed frame laser pipe cutting machine, focus on these criteria:

(1) Tube Compatibility

- Must handle the full range of bed frame profiles (square, oval, angle steel, H‑beam).

- Look for chucks or clamping systems that switch seamlessly between shapes without downtime.

(2) Precision & Cut Quality

- Aim for ±0.1 mm accuracy to ensure holes and bevels align perfectly during assembly.

- Laser cuts should be smooth and burr‑free to avoid rework or secondary finishing.

(3) Automation Level

- A fully automated line—automatic loading/unloading, integrated punching module, robotic handling and downstream bending—dramatically reduces labor and cycle time.

- True lights‑out operation (24/7) maximizes throughput in high‑volume runs.

(4) Minimum Tailing & Waste Reduction

- Advanced front‑chuck designs can limit leftover “tail” to as little as 40 mm, improving material utilization and lowering scrap costs.

(5). Laser Power & Speed

- A 1.5–6 kW fiber Tube Laser Cutting Machine generally covers carbon steel, stainless steel and aluminum commonly used in furniture.

- Match power to desired throughput—a higher‑power source boosts cutting speed on thicker sections.

(6) Mechanical Stability & Vibration Resistance

- Thin‑walled tubes are prone to distortion if the machine frame or motion components vibrate.

- Rigid gantry designs and advanced control systems (e.g. FSCUT nesting software) ensure smooth, high‑acceleration moves without chatter.

(7) Industry‑Specific Features

- Support for bevel cutting at various angles, precise hole location for brackets or connectors, and CAD/CAM integration all enhance flexibility.

- An embedded punching function or ability to preload multiple punch patterns can save an entire secondary operation.

Solution: Full-Line Automation for Bed Frame Pipe Processing

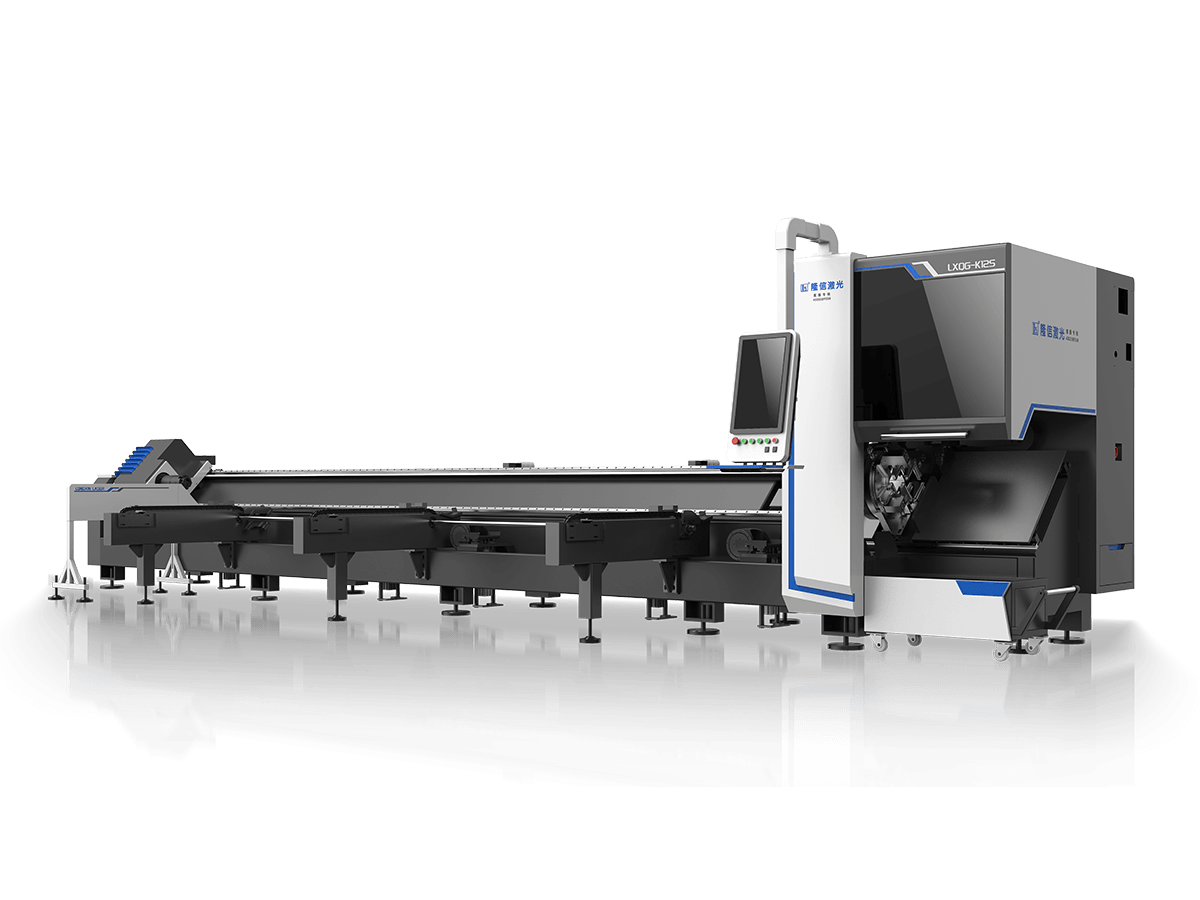

To meet the client’s needs, Longxin Laser deployed a fully automated laser pipe cutting production line built around the LX-K12S laser cutting machine, complemented by:

(1) Automatic loading & unloading system

This system automatically feeds raw tubes into the laser cutter and transports finished parts out—eliminating manual loading downtime.

(2) Batch punching unit

The integrated punching module processes holes (round, square, slots) in one go—no secondary drilling needed. It’s optimized for high-volume, repetitive holes common in bed frame fabrication.

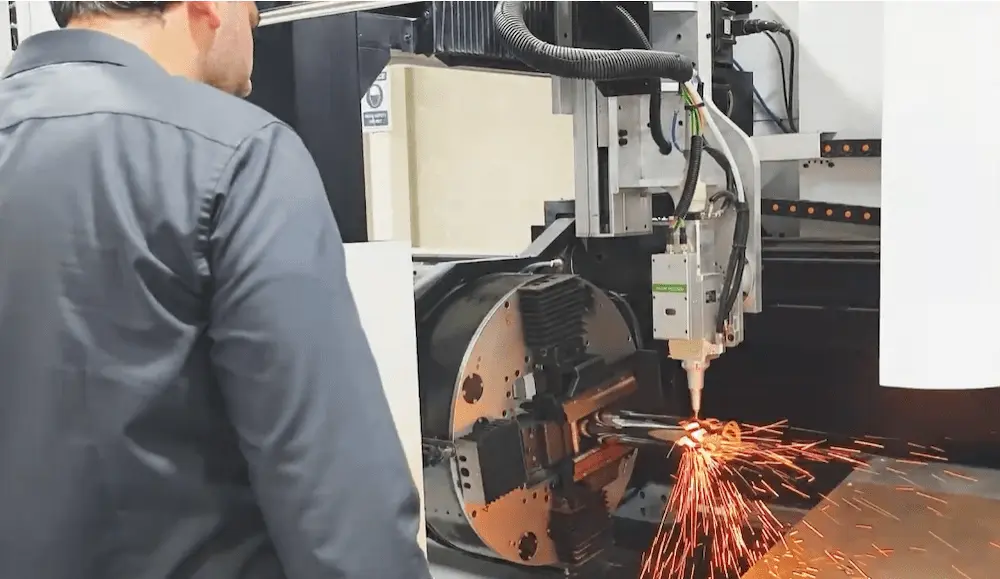

(3) Robotic arm for pipe handling

Robotic manipulators move cut and punched tubes between stations—without operator input. This ensures precise alignment and handling, enabling a smooth handoff to downstream processes like bending. Such integration helps sustain continuous operation with minimal human supervision

(4) CNC pipe bending machine

The bending module automatically shapes cut tubes into bed frame components following CAD designs. It works downstream of the laser line to perform precise bends at specific angles (e.g. corners or frame curves), finishing the tube components for final welding or assembly.

This smart line allows continuous, unattended operation 24/7, suitable for both large and small tube processing tasks common in bed frame manufacturing.

Key Features of the Bed Frame Laser Pipe Cutting Machine

The LX-K12S is designed for high-precision and high-speed cutting of metal tubes, especially suited to furniture and light industry applications. Key features include:

-

Laser power options from 1500W to 3000W for cutting materials like stainless steel, carbon steel, aluminum, and more.

-

Cutting capacity: Ø10–120 mm round tubes, 10×10–120×120 mm square tubes.

-

Tiny tube optimization: mechanical and software systems are tuned for cutting small pipes with high accuracy (±0.1 mm).

-

Minimal tailing: as low as 40 mm thanks to front chuck design.

-

Wide material compatibility: works with H-beams, angle steel, oval pipes, and special-shaped profiles.

-

Full automation: from loading to cutting — no manual intervention required.

This system not only cut bed frame tubes to size with precision but also integrated punching and bending steps to streamline post-cutting operations.

Results & Impact

✅ Labor Reduction: The client cut down 80% of manual labor in tube cutting and handling.

✅ 24/7 Operation: The entire line runs around the clock with minimal human supervision.

✅ Output Boost: Production efficiency increased by over 40% due to automation and multi-process integration.

✅ Precision Improvement: Seamless robotic handling ensured uniformity and precision in every bed frame component.

Takeaways for Bed Frame Manufacturers

If you manufacture bed frames or other steel tube-based furniture, investing in a bed frame laser pipe cutting machine with full-line automation like the LX-K12S can dramatically transform your workflow. It’s a scalable, cost-effective solution for businesses aiming to compete in a high-volume, precision-demanding market.

Want to Upgrade Your Pipe Cutting Workflow?

Longxin Laser specializes in intelligent pipe cutting solutions for furniture, automotive, fitness, construction, and other industries. Talk to our experts and find the right laser solution for your factory.

Kontaktiere uns Today to explore your automation upgrade.