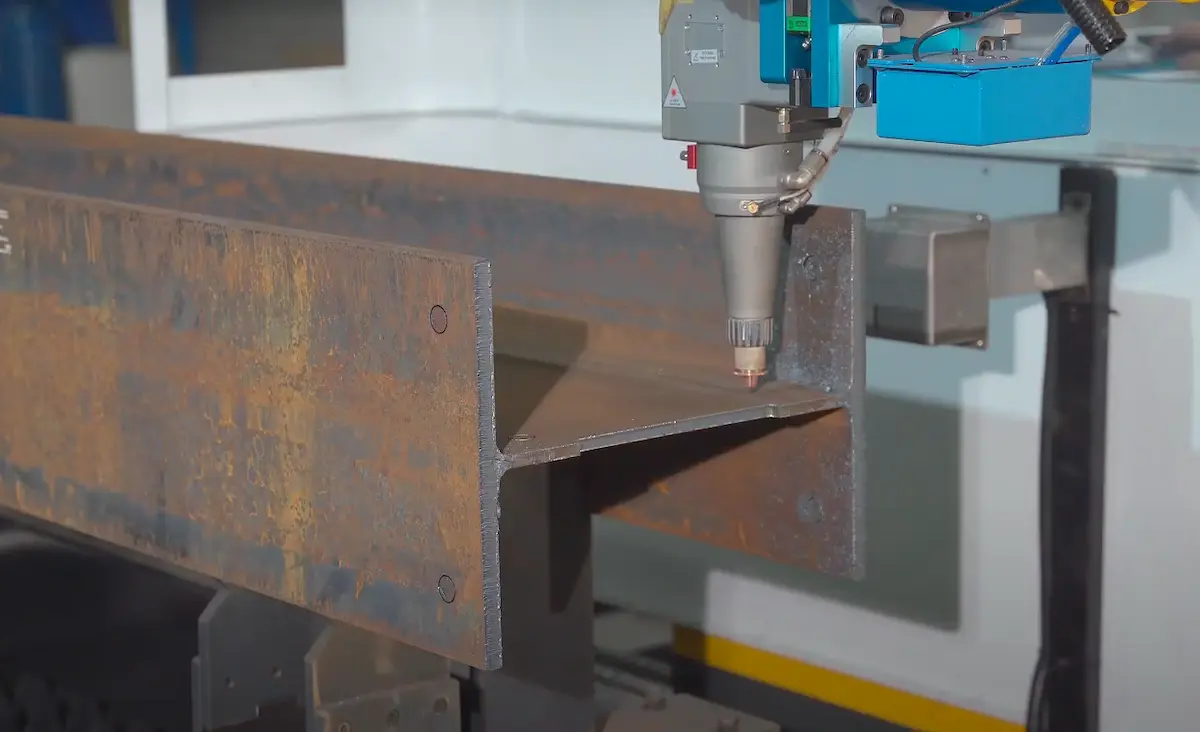

Are you a exhaust pipe manufacturer looking for a cutting-edge solution to boost your production efficiency and quality? Look no further! As a leading laser cutting machine manufacturer with a long history of twenty years, we understand your needs, and our GL Series machines are the ideal choice for pipe manufacturers. Here’s why:

Fully Automated Production

The GL Series machines come equipped with an automated loading system, enabling seamless, end-to-end automation from material loading to precision cutting and unloading. This means reduced labor costs and a substantial increase in overall productivity for exhaust pipe manufacturing facilities.

User-Friendly Operation

Our GL Series machines feature a user-friendly operating system developed in-house. You don’t need to be a laser cutting expert to operate them. With just a few key parameters, you can achieve fully automated cutting. Even operators with no prior experience can quickly learn and master the process.

Residue-Free Cutting for Pristine Pipe Interiors

Maintaining the cleanliness of the inner walls of pipes is a non-negotiable requirement for pipe manufacturers. The GL Series machines are equipped with a servo-driven residue removal system that significantly minimizes the risk of molten residue contaminating the pipe’s interior. This ensures that your pipes stay consistently clean and pristine.

Exceptional Cutting Efficiency

The GL Series pipe cutting machines boast an impressive 1.5G acceleration and can achieve a maximum feed rate of 138 meters per minute. Combined with a high-precision drive structure, they can cut a single workpiece in less than one second. This efficiency improvement, up to 3-4 times faster than traditional saw cutting, allows one machine to handle large-scale production tasks with ease.

Unbeatable Value for Your Investment

The GL Series offers exceptional value for its price, with a laser lifespan of up to 100,000 hours. The machine frame undergoes a high-temperature treatment process at 650°C, followed by stress relief annealing, which significantly extends the machine’s lifespan. Even during continuous, long-term operation, these machines can deliver 15-20 years of service.

In summary, the GL Series laser cutting machines are the perfect fit for pipe manufacturers seeking an advanced, cost-effective solution that offers automation, ease of use, residue-free cutting, high efficiency, and unmatched durability. Elevate your pipe production to new heights with the GL Series, your partner in precision and performance.

Make the smart choice today – choose GL Series for yourexhaust pipe manufacturing needs!