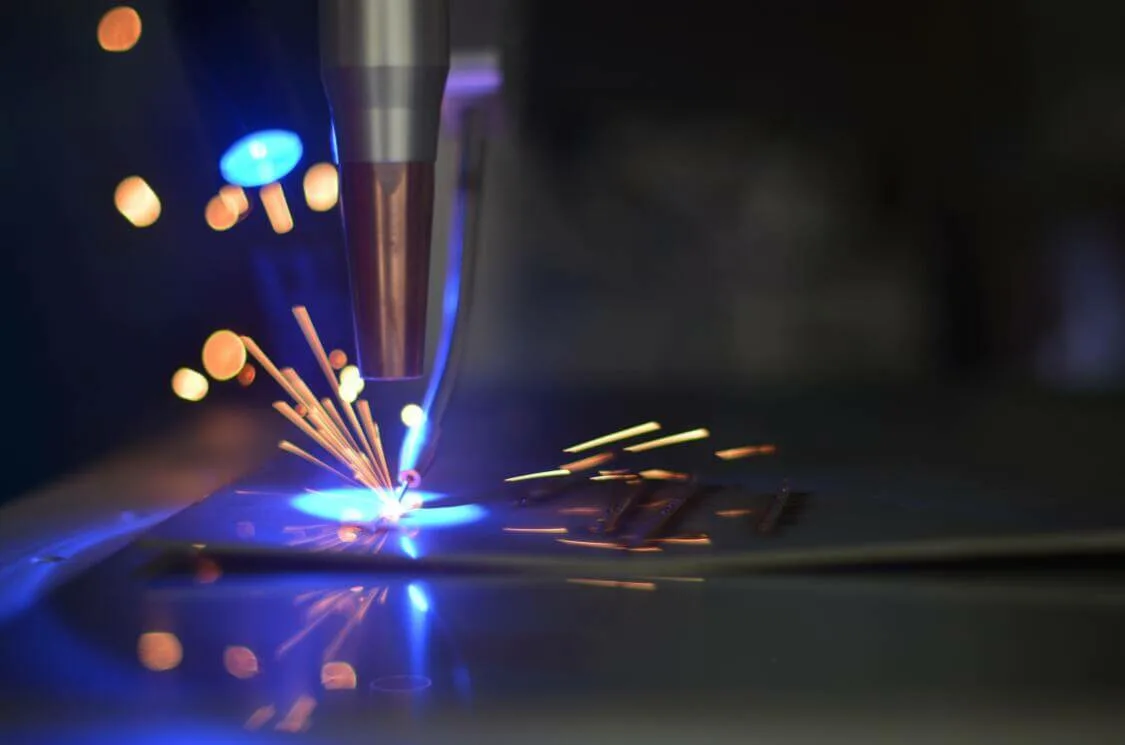

Laser tube cutting machines are incredibly efficient tools used in various industries for precise and high-speed cutting of metal tubes. However, like any advanced machinery, they can encounter issues that disrupt their operation. Understanding common problems and their solutions can help maintain your machine’s performance and extend its lifespan. Here’s a guide to common troubleshooting tips for laser tube cutting machines.

1. Cutting Quality Issues

Symptoms: Rough edges, burrs, and uneven cuts.

Possible Causes:

- Puissance laser: Insufficient or unstable laser power.

- Vitesse de coupe: Incorrect cutting speed for the material.

- Optics: Misaligned laser beam or dirty focusing lens.

Solutions:

- Adjust Laser Power: Ensure the laser power matches the material’s requirements.

- Optimize Cutting Speed: Adjust the cutting speed to suit the material thickness and type.

- Check Optics: Regularly clean the focusing lens and align the laser beam properly.

2. Laser Head Collisions

Symptoms: The laser head bumps into the workpiece.

Possible Causes:

- Incorrect Material Diameter Setting: The diameter of the material is not set correctly in the machine.

- Incorrect Nozzle Height: The nozzle height is set too low.

Solutions:

- Measure Material Diameter: Ensure the material diameter is accurately set.

- Adjust Nozzle Height: Increase the nozzle height to prevent collisions.

3. Piercing Issues

Symptoms: Long piercing times and inaccurate piercing points.

Possible Causes:

- Laser Power Settings: Inappropriate power settings for piercing.

- Gas Pressure: Incorrect gas pressure.

Solutions:

- Adjust Power Settings: Optimize the laser power specifically for piercing operations.

- Check Gas Pressure: Ensure the gas pressure is suitable for the material and piercing process.

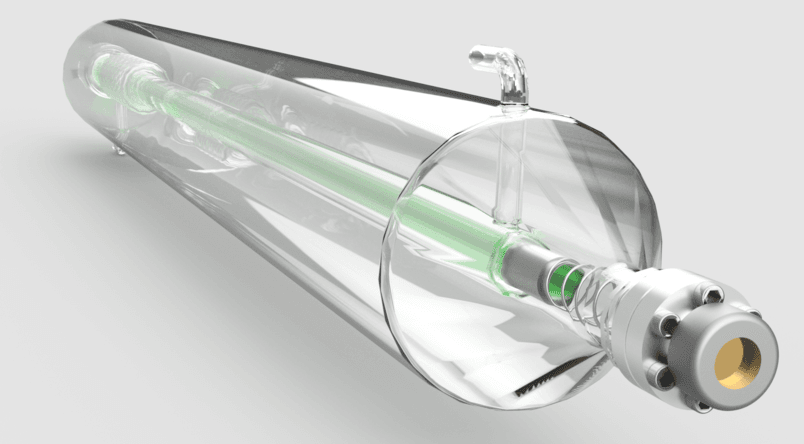

4. Laser Power Decrease

Symptoms: Reduced cutting capability, unable to cut through materials.

Possible Causes:

- Laser Source Degradation: The laser source may be aging or degrading.

- Cooling System Issues: Inefficient cooling can cause the laser source to overheat.

Solutions:

- Maintain Laser Source: Regularly check and maintain the laser source. Replace if necessary.

- Ensure Efficient Cooling: Check the cooling system, replace coolant regularly, and ensure it’s functioning correctly.

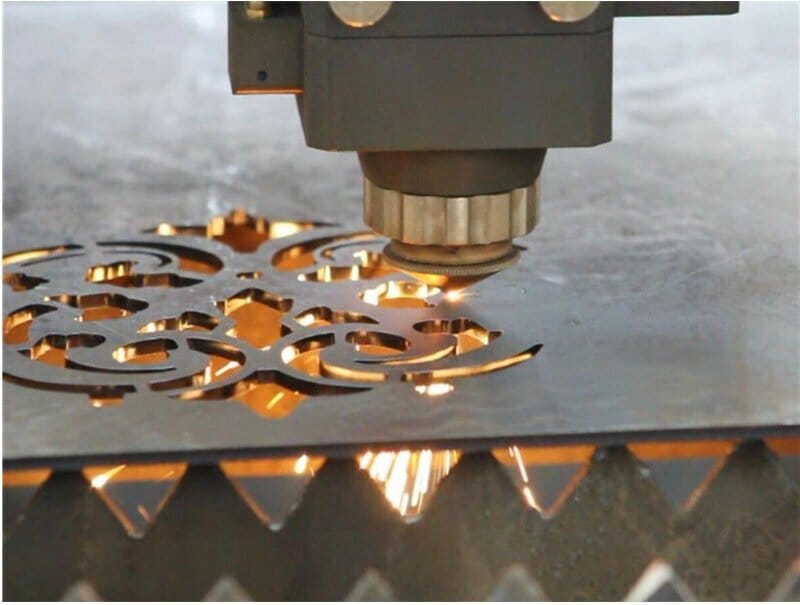

5. Cutting Path Deviations

Symptoms: The cut path does not follow the intended design.

Possible Causes:

- Software Errors: Issues with the cutting program or software.

- Mechanical Issues: Problems with the drive system or mechanical components.

Solutions:

- Check Software: Review and correct the cutting program.

- Inspect Mechanics: Ensure all mechanical parts, such as gears and belts, are in good condition and properly aligned.

6. Gas Supply Problems

Symptoms: Unstable cutting performance, inconsistent cuts.

Possible Causes:

- Gas Pressure: Incorrect or unstable gas pressure.

- Gas Quality: Low-quality gas affecting the cutting process.

Solutions:

- Adjust Gas Pressure: Set the gas pressure to the correct level for the material being cut.

- Use High-Quality Gas: Ensure you are using high-quality gas suitable for laser cutting.

Preventive Maintenance Tips

To minimize downtime and extend the life of your laser tube cutting machine:

- Regular Cleaning: Keep optical components and the machine clean.

- Routine Inspections: Regularly inspect mechanical and electronic parts for wear and tear.

- Update Software: Keep the machine’s software and firmware updated.

- Cooling System Maintenance: Regularly check and maintain the cooling system.

Conclusion

Understanding and addressing common issues in laser tube cutting machines can significantly improve their performance and longevity. Regular maintenance and prompt troubleshooting are key to ensuring your machine operates efficiently. If problems persist, consult with a professional technician or the machine’s manufacturer for further assistance.