In the world of manufacturing and fabrication, precision and efficiency are paramount. Among the myriad tools and technologies employed in these industries, laser cutting machines stand out for their ability to deliver intricate cuts with unparalleled accuracy. But how exactly does a laser cutting machine work its magic? Let’s delve into the inner workings of this remarkable technology.

Introduction to Laser Cutting

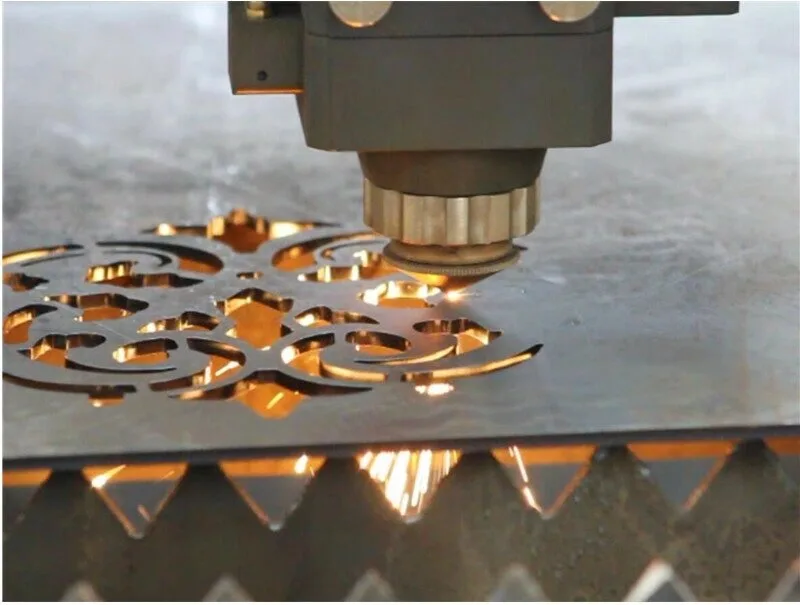

Laser cutting is a process that utilizes a high-powered laser beam to cut through materials such as metal, wood, plastic, and glass. It offers numerous advantages over traditional cutting methods, including superior precision, speed, and versatility. From automotive parts and aerospace components to intricate artistic designs, laser cutting finds applications across various industries.

The Basic Components

At its core, a laser cutting machine comprises several key components working in harmony to achieve precise cuts. These components include:

1.Laser Source:

The heart of the system, the laser source generates the intense beam of coherent light used for cutting. Common types of lasers used in cutting machines include CO2 lasers and fiber lasers, each offering unique advantages depending on the application.

2.Laser Optics:

Once generated, the laser beam is directed and focused onto the workpiece through a series of mirrors and lenses. These optics ensure that the beam remains concentrated and accurately targeted, enabling precise cuts.

3.CNC Controller:

The cutting process is typically controlled by a computer numerical control (CNC) system. This system translates digital design files into precise instructions for the laser cutting machine, dictating the path and parameters of the cutting operation.

4.Workpiece Support:

The workpiece, or material being cut, is securely held in place on the machine’s worktable or bed. Proper support and alignment are essential to ensure accurate cutting and prevent material deformation.

The Cutting Process

Now, let’s walk through the step-by-step process of how a laser cutting machine operates:

1. Preparation:

The process begins with the preparation of the digital design files that specify the desired cuts. These files are typically created using computer-aided design (CAD) software, allowing for precise customization and optimization of the cutting patterns.

2. Material Setup:

The workpiece is placed on the machine’s worktable, ensuring proper alignment and fixation to prevent movement during cutting. Depending on the material and application, additional preparations such as surface cleaning or masking may be necessary.

3. Beam Generation:

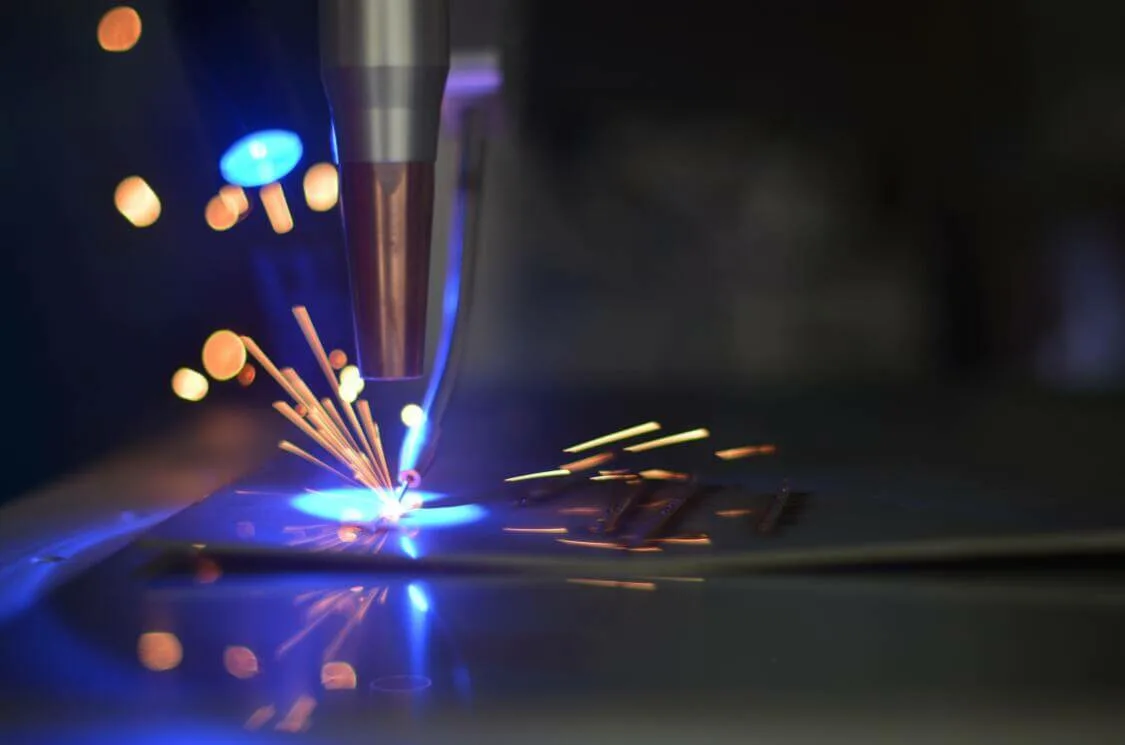

With the material in place, the laser source is activated, emitting a concentrated beam of coherent light. The type and intensity of the laser beam are carefully selected based on the material being cut and the desired cutting parameters.

4. Beam Focusing:

The laser beam is directed through a series of mirrors and lenses, which focus it onto the surface of the workpiece with pinpoint accuracy. Proper focusing is critical to achieving clean cuts with minimal kerf width (the width of material removed by the laser).

5. Cutting Operation:

Once the beam is properly focused, the cutting operation begins. The CNC controller precisely controls the movement of the laser beam along the programmed cutting path, guiding it through the material with high speed and accuracy.

6. Material Removal:

As the laser beam interacts with the workpiece, it heats and vaporizes or melts the material along the cutting path. The molten or vaporized material is then blown away by assist gases such as nitrogen or oxygen, leaving behind a clean, precise cut.

7. Cooling and Solidification:

After the cutting is complete, the newly formed edges of the cut undergo rapid cooling and solidification. Proper cooling helps prevent distortion and warping of the material, ensuring dimensional accuracy and quality of the finished parts.

8. Post-Processing:

Depending on the specific requirements of the application, additional post-processing steps such as deburring, cleaning, or surface treatment may be performed to refine the cut edges and enhance the final product’s appearance and functionality.

Advantages of Laser Cutting

Laser cutting offers several distinct advantages over traditional cutting methods, making it a preferred choice for many manufacturing and fabrication processes. Some of the key benefits include:

Précision:

Laser cutting machines can achieve extremely high levels of precision, allowing for intricate designs and tight tolerances.

Speed:

With fast cutting speeds and minimal setup time, laser cutting enables efficient production and quick turnaround times.

Versatility:

Laser cutting can be applied to a wide range of materials, including metals, plastics, ceramics, and composites, making it suitable for diverse applications.

Minimal Material Waste:

The focused nature of the laser beam results in narrow kerf widths and minimal material wastage, maximizing material utilization and reducing costs.

Automation:

Integrated CNC control and automation capabilities streamline the cutting process, increasing productivity and minimizing human error.

Conclusion

In conclusion, a laser cutting machine is a sophisticated tool that harnesses the power of focused light to achieve precise and efficient cutting of various materials. By understanding the fundamental principles and processes involved, manufacturers and fabricators can leverage this advanced technology to unlock new possibilities in design, production, and innovation. As laser cutting continues to evolve and advance, its role in shaping the future of manufacturing is poised to grow, driving progress and excellence across industries.