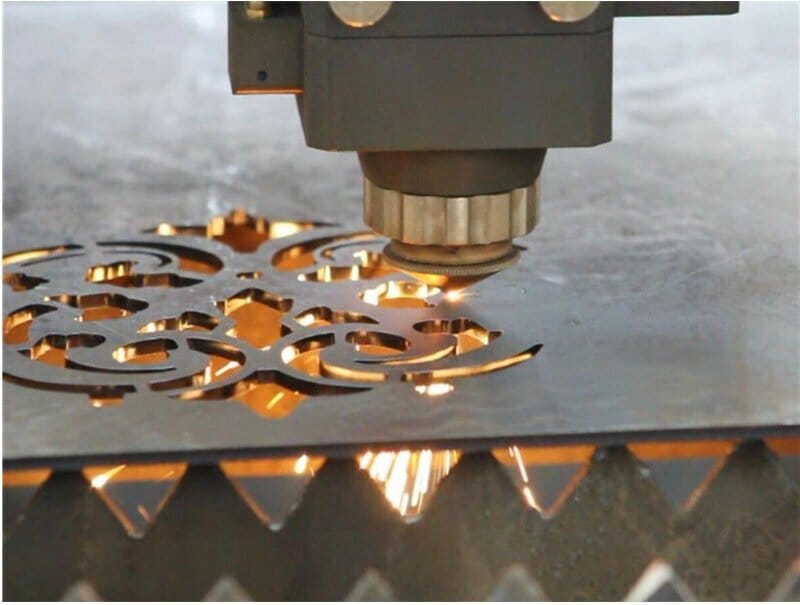

In today’s manufacturing industry, precision and efficiency are crucial. Laser tube cutting machines have become indispensable tools, revolutionizing the way the industry handles pipe and tube cutting tasks. However, one question that users often raise is: “What is the service life of a laser tube cutting machine?”

The service life of a laser tube cutting machine depends on various factors, from its manufacturing quality and maintenance to technological advancements. Let’s delve deeper into this topic for a comprehensive understanding.

Component system service life:

To measure the service life of a laser tube cutting machine, we need to understand the lifespan of each component system. A laser tube cutting machine can be divided into several main systems:

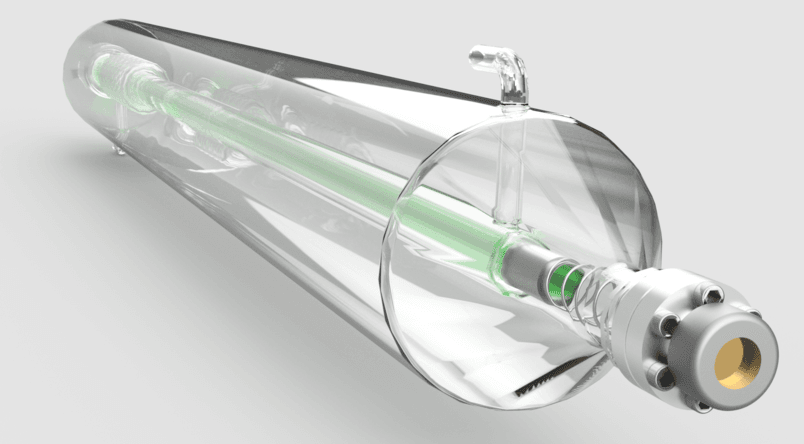

1.Laser System:

- Laser Source: The laser source is the heart of the cutting machine. Different types of lasers (such as CO2 lasers and fiber lasers) have different service lives. The theoretical service life of a fiber laser is around 30,000 hours, while that of a CO2 laser is around 12,000 hours. However, the actual service life of the machine varies depending on each customer’s usage and maintenance.

- Optical System: This includes lenses, mirrors, and optical fibers, which control and focus the laser beam for precise cutting and processing. While lenses generally have a long service life, they require regular cleaning and maintenance.

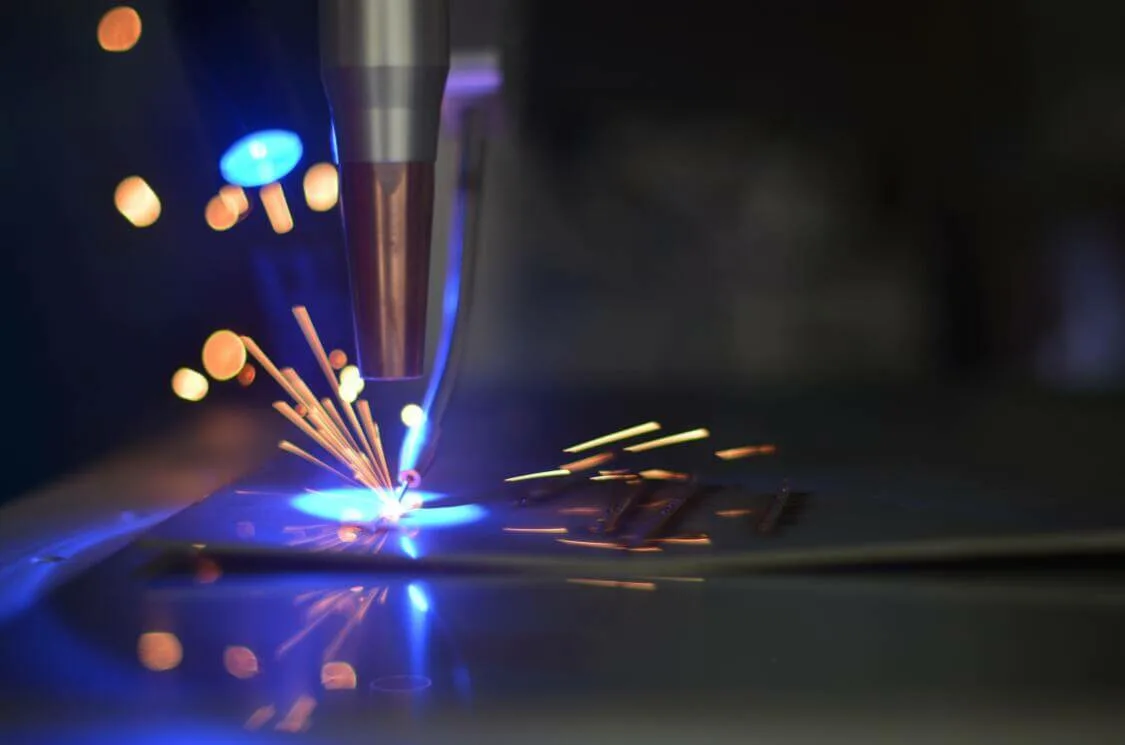

2.Cutting Head:

- The cutting head contains optical components that focus the laser beam onto the material. It consists of focusing lenses, protective lenses, and copper nozzles. Protective lenses and copper nozzle cutting heads are consumable parts that need to be replaced during use. It is recommended to replace them every three months under normal conditions to maintain cutting accuracy, quality, and speed.

3.Motion System:

- Pneumatic Chuck: Pneumatic chucks play a crucial role in fixing and clamping the tube material, ensuring its stability during cutting. With a fully enclosed structure and excellent material selection and heat treatment processes, pneumatic chucks can have a service life of over three years.

- Machine Components: Components such as linear guides, ball screws, servo motors, and drives support the movement of the tube material. A robust machine bed can withstand heavier tube materials, while a high-quality motion system can withstand heavy use while maintaining precision. These components typically have long service lives, ranging from 5 to 10 years.

4.Control System:

- Computer Controller: Software systems that control the entire cutting process.Motion Control System: Controls the machine’s motion trajectory and speed, ensuring cutting accuracy and efficiency.

- Laser Power Control System: Controls the intensity and stability of the laser beam to meet the cutting requirements of different materials and thicknesses.

- Control systems operate at the software level and do not have a physical lifespan like hardware. However, to achieve the best compatibility and ensure cutting accuracy with each tube, it is essential to have an up-to-date control system. If your control system has been in use for many years and new-generation systems are available on the market, or if there are new safety and regulatory requirements, updating the control system may be necessary

5.Auxiliary Systems:

- Cooling System: Used to cool the laser and optical components, preventing overheating damage. The service life of a chiller is typically between 8 to 12 years, as they are durable.

- Waste Disposal System: Manages waste and exhaust generated during the cutting process to ensure a clean environment and safe operatio

- Safety System: Includes protective enclosures, emergency stop buttons, safety light curtains, and other safety devices to protect operators from laser radiation and mechanical hazards. The lifespan of safety light curtains generally ranges from 100,000 to 500,000 hours, depending on factors such as usage environment, operating temperature, frequency, and quality.

- All these systems work together to form a complete laser tube cutting machine system, used for efficient and precise cutting of various types of tube materials

Factors affecting service life:

1.Component Quality:

The quality of components used in each brand of laser tube cutting machine varies. Machines made with high-quality components typically have longer service lives and require fewer repairs. Investing in a reputable brand known for durability can bring long-term returns, even if it requires a higher initial investment. Trust me, when your laser tube cutting machine requires frequent repairs, you end up spending more money.

2.Maintenance Practices:

Regular maintenance, including cleaning, lubrication, and inspection, is crucial for extending the service life of a laser tube cutting machine. It is best to follow the manufacturer’s recommendations, read the machine manual thoroughly, and develop a maintenance plan to prevent premature wear and damage.

3.Working Environment:

The working environment significantly affects the service life of a laser tube cutting machine. Environmental factors such as temperature, humidity, dust, and chemical gases can accelerate the aging and damage of machine components. Proper ventilation and climate control help maintain the machine’s condition.

4.Work Intensity:

Usage intensity and frequency play an essential role in determining the service life of a laser tube cutting machine. Heavy-duty industrial applications may result in faster wear compared to light-duty scenarios. Although many brands claim their laser tube cutting machines can work continuously for 24 hours, whether this can be achieved depends on several factors, including the machine’s design and manufacturing quality, operating environment, maintenance, and management practices. Prolonged continuous operation may increase the risk of machine wear and failure. Therefore, it is recommended to schedule rest and maintenance time appropriately during 24-hour operations to extend the machine’s service life.

5.Technological Updates:

With technological advancements, new technologies and improvements emerge continuously. Laser cutting machine manufacturers are also constantly upgrading manufacturing processes. Machines that can be upgraded with new software and hardware will have a longer service life, similar to OTA updates in new energy vehicles, which can repair bugs and reduce errors.

How to extend the service life of a laser tube cutting machine?

- Ensure an excellent working environment when using the laser cutting machine, avoiding adverse effects on the equipment as much as possible.

- Regularly inspect the equipment to ensure it is in good condition.

- Use original spare parts and choose formal manufacturers for repairs and maintenance.

- Follow the prescribed operation methods for using the equipment.

- Replace consumable parts according to the equipment’s usage time regulations.

- The most crucial point, which many people overlook, is to choose a reliable seller at the time of purchase and select products that have been tested over time