Obviously this is an interesting question, let’s discuss it today:

conclusion:

Let’s put the conclusion first: laser can theoretically cut stone. However, this is limited to carving softer stones, such as softer marble, plaster and other materials.

For some harder stones (such as granite, limestone, etc.), the laser cutting effect is not ideal unless a high-power, long-pulse-width laser is used. Moreover, lasers cannot cut cloth, leather, glass, plastic and other non-metals. The reason is simple. The wavelength range of the fiber laser cutting machine is not within the absorption range of the above materials, or the absorption is inappropriate and the ideal cutting effect cannot be achieved.

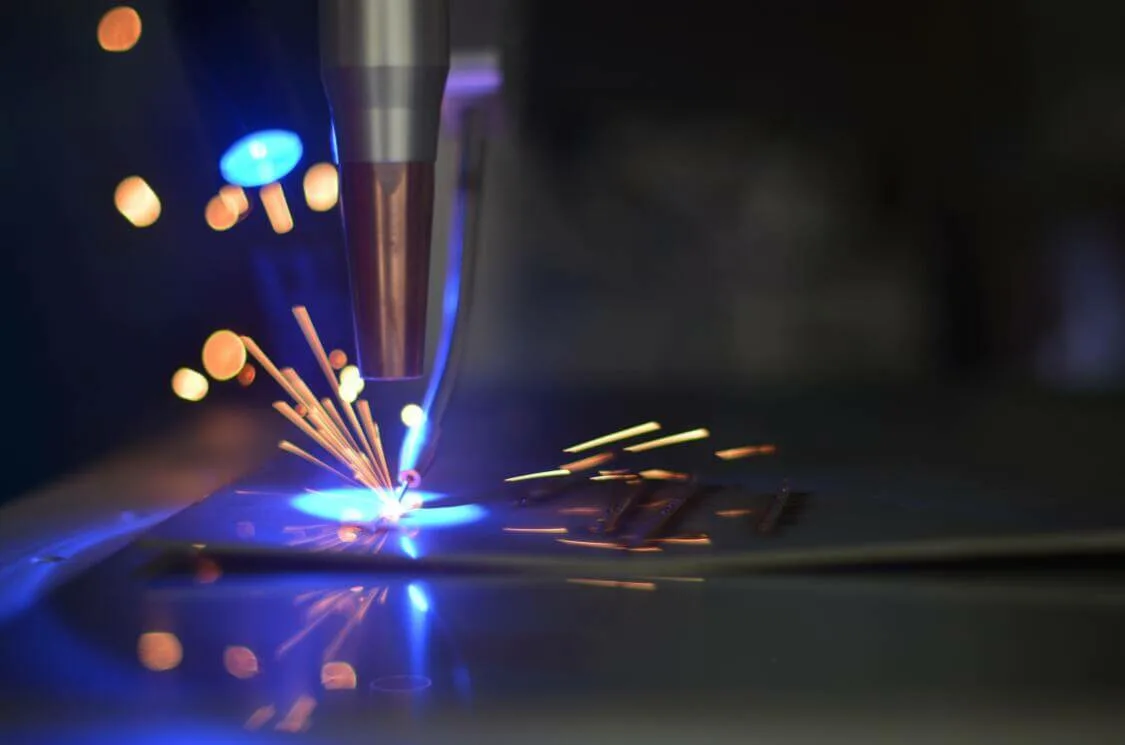

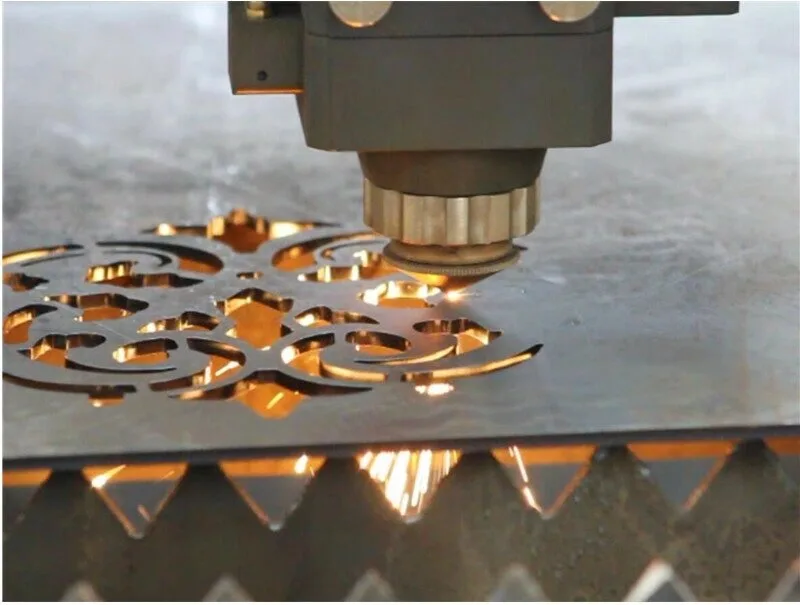

At present, macchine per il taglio laser di tubi have no advantages in cutting non-metals. The principle of metal laser cutting machine is to melt the workpiece through laser beam irradiation. Suitable materials are iron, stainless steel, carbon steel and other metal materials.

Secondly, fiber laser cutting machines are not recommended for long-term cutting of aluminum, copper and other rare metal materials, because these materials are highly reflective materials (note: high reflection has little to do with the smoothness of the cutting surface of the plate, mainly because the wavelength of the laser is not Within the ideal absorption range of these materials, the absorption effect is not good, most of the energy is reflected back, and the protective lens in front of the laser head is easily damaged), the long-term use effect is not good, and the usage of consumables is increased.

Fiber laser cutting machines cannot cut flammable materials such as wooden boards. Fiber laser cutting machines are thermal processing. When cutting objects made of flammable materials such as wood boards, the surface of the material will be heated and spontaneous combustion will occur. As a result, the precision of the cut objects cannot meet the cutting requirements. Therefore, such objects cannot be cut.

Finally, fiber laser cutting machines, depending on their power, will also change the cutting thickness. The greater the power, the greater the cutting thickness, the thinner the metal material, and the faster the cutting speed. The fiber laser cutting machine has obvious advantages for thin plate cutting.