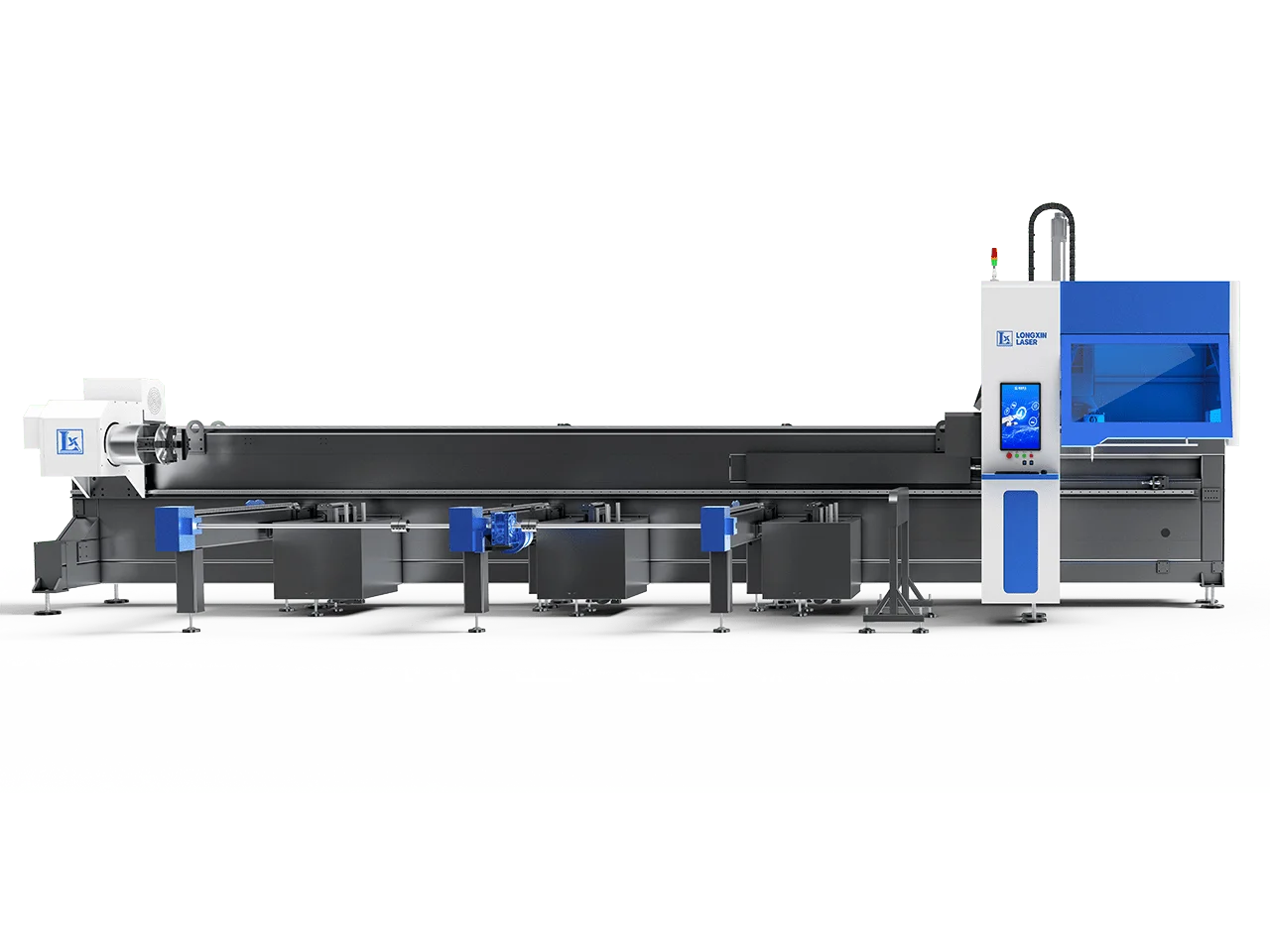

Dual Chuck-Zero Scrap-Laser Tube Cutting Machine

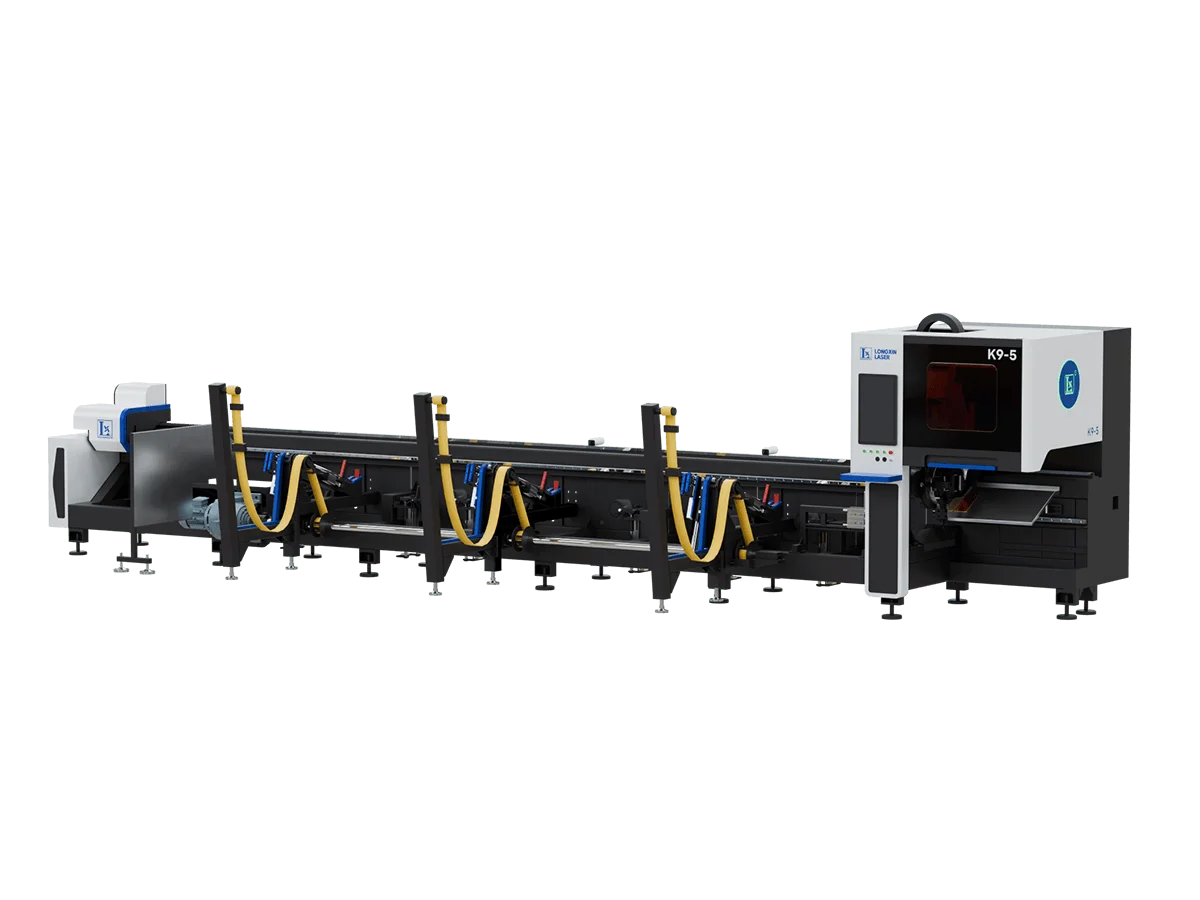

LX-K9-5

- Dual chuck system with zero scrap functionality

- Maximum acceleration of 2.0G – Delivers exceptional cutting speed

- Next-gen self-developed material prep system – Eliminates waiting time during loading

- Optional configurations:

- Follow-up loading/unloading

- Pneumatic loading/unloading

Product Features

Dual Chuck, Zero Scrap

Maximized material utilization – Offers multiple scrap-cutting modes for optimal efficiency.

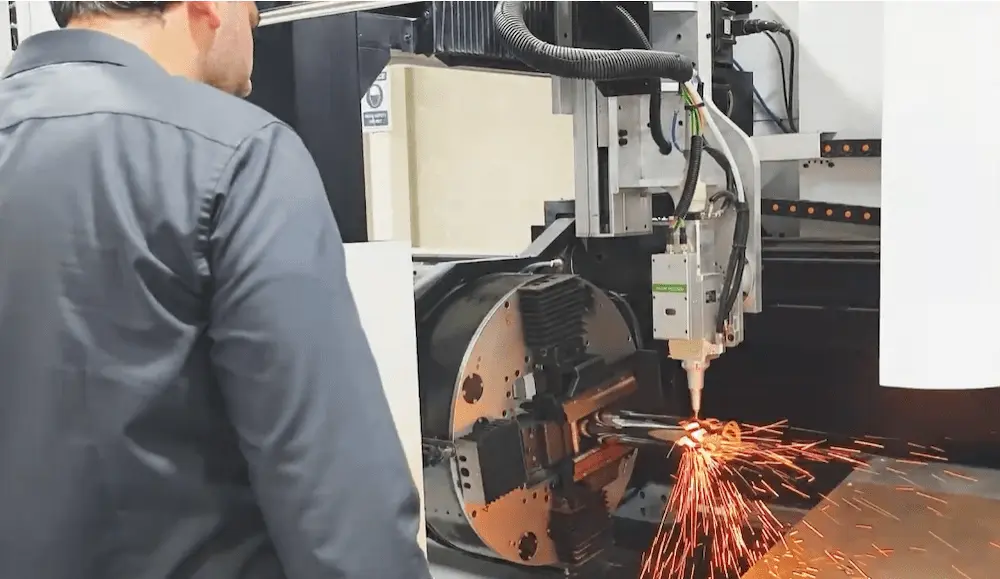

Slag-free cutting

Molten slag is removed simultaneously during cutting, resulting in near-zero residue. significantly reduces the cost of dust removal systems.

Ultra-High Speed

2.0G acceleration – The K9-5 delivers unmatched cutting speed and efficiency.

No Drawing Needed — Just Input & Cut

The built-in intelligent system replaces manual drafting. Enter the required parameters, and 3D models are generated instantly for efficient and precise cutting.

50% increase in loading efficiency

Featuring a side-mounted bed structure, the machine completes each loading cycle in just 10 seconds.

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

Video

Need more information? Contact us today and we can set up a confidential meeting to discuss your project.

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Cutting Samples

Customer Case

Korea’s Leading Steel Structure Manufacturer Upgrades Production with Longxin Laser LX-T35 Three-Chuck Bevel Tube Cutting Machine

How Longxin LX-K24 3D Laser Tube Cutting Machine Boosted Jinjia Building Materials’ Productivity by 20%

Dubai Construction Client Boosts Productivity with Longxin LX-K28 Three-Chuck Laser Tube Cutting Machine

Longxin Laser Machine LX-K6 in South Africa

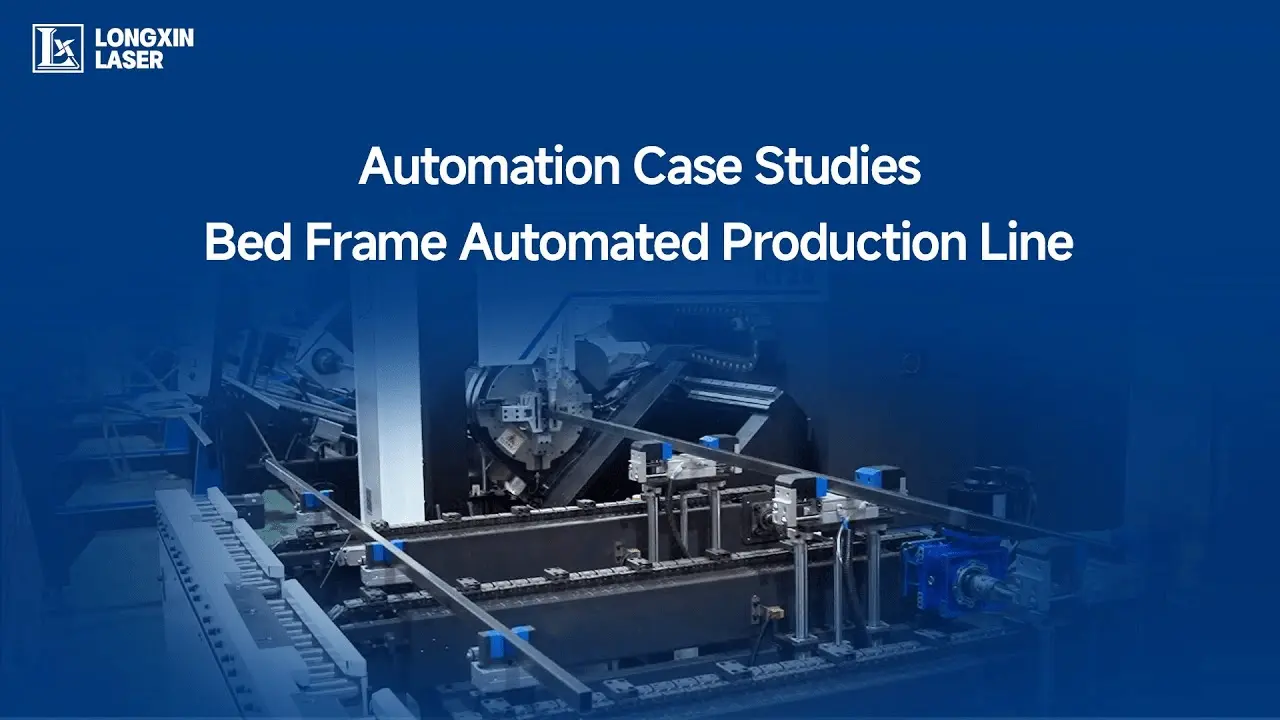

Bed frame laser pipe cutting machine production line case study

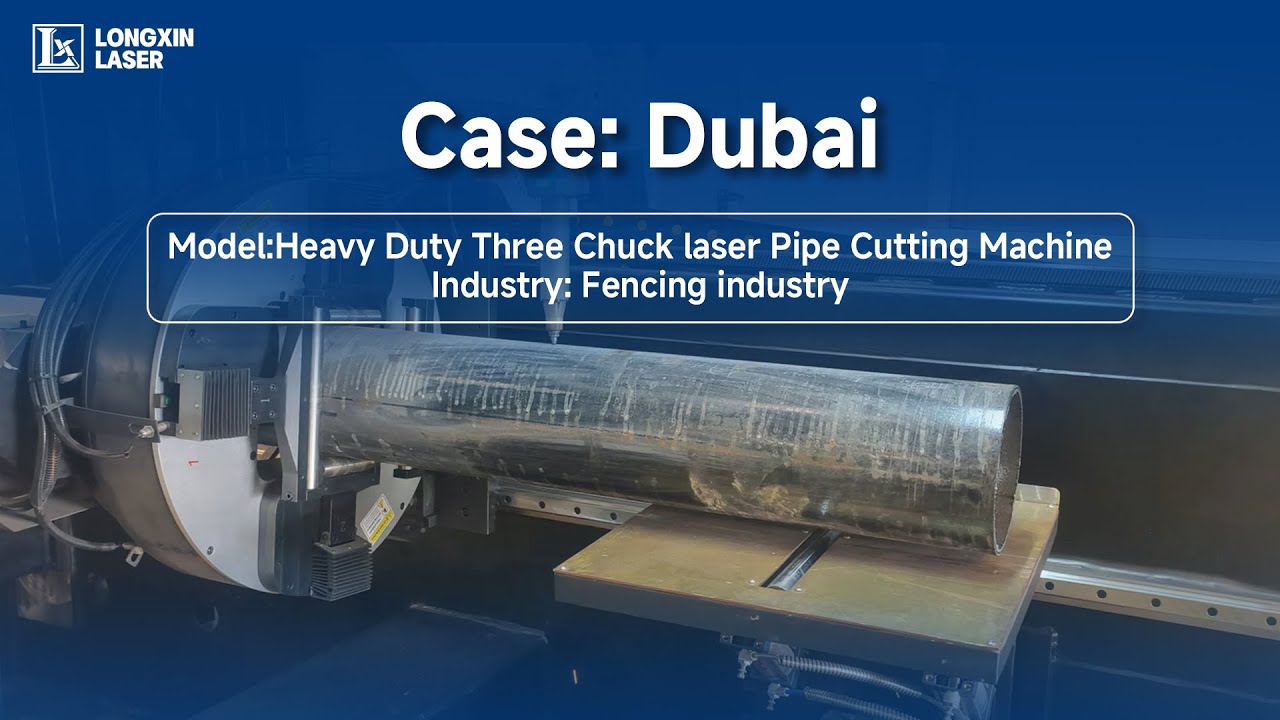

Customer Case: Dubai – High-Power Tube Laser Cutting for the Fencing Industry

Automated High‑Speed Tube Cutting & Chamfering in Türkiye

Longxin Laser Pipe Cutting Machine K9max Helps Indonesia’s Metal Pipe Industry Upgrade Automation

Racing Ahead: Transforming Bracket Manufacturing – Longxin laser

Why longxin laser?

Cutting-edge technology

We utilize the most advanced laser tube cutting technology to ensure precision and high quality in every product.

Extensive experience

With 15+ years tube cutting experience, we understand what your needs.

Efficient Production

Our production line runs efficiently, producing over 300+ machines per month.

Custom automation

We offer a specialised, bespoke service to meet your needs.

Customer Support

Our dedicated after-sales service team is always ready to assist you

Smart software

Highly integrated intelligent tube cutting solutions

Related Products

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.