Client Profile

A leading automotive parts manufacturer based in Istanbul, Turkey, specializing in exhaust systems and structural components for both domestic and European markets.

Challenge

The company faced increasing pressure to improve precision, efficiency, and flexibility in their production of tubular components, particularly for exhaust systems using 28mm and 22mm diameter circular tubes.

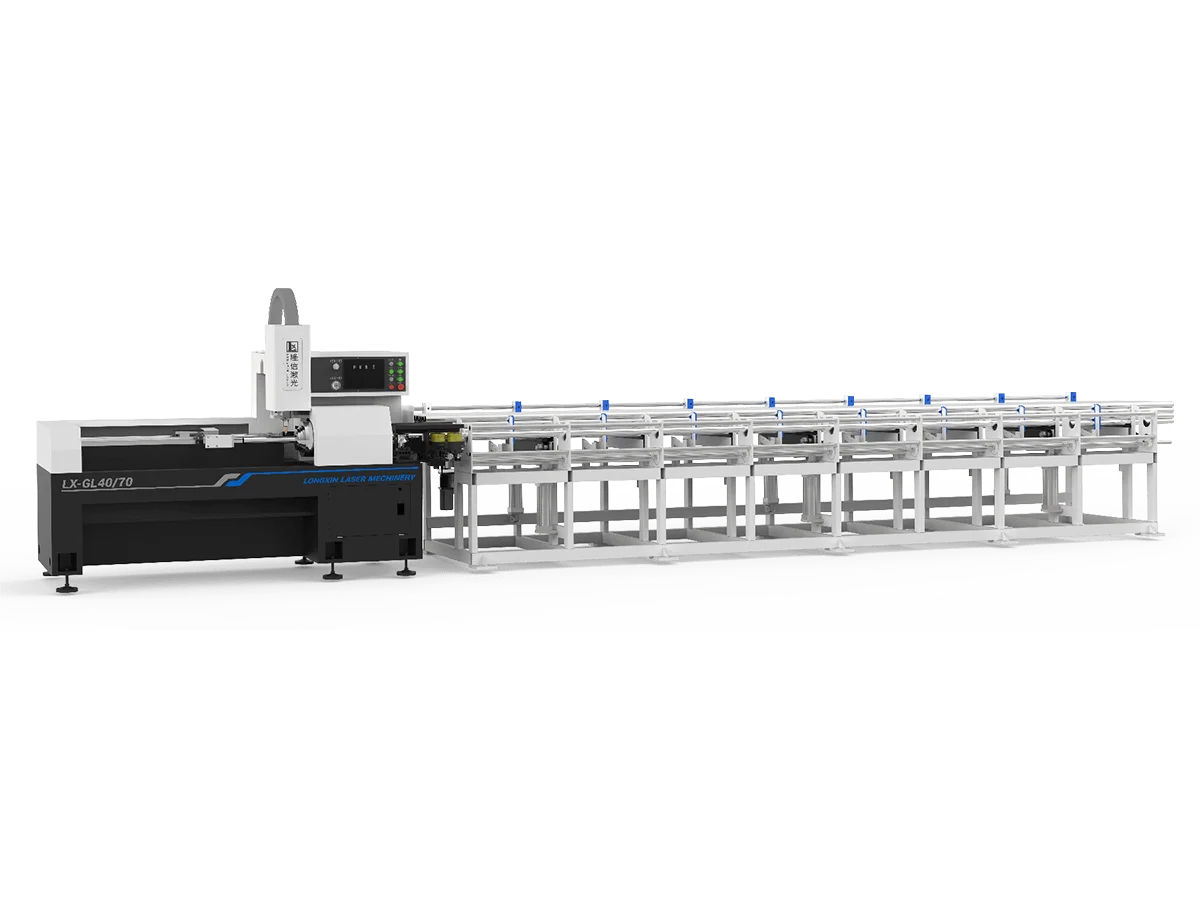

Solution: LX-GL40 Laser Tube Cutting Machine

The manufacturer implemented the LX-GL40 laser tube cutting machine from Longxin Laser, chosen for its advanced features and suitability for automotive applications.

Key Features of LX-GL40:

- Precise cutting of circular tubes with diameters ranging from 20mm to 120mm

- High-speed processing capabilities

- Advanced CNC control system for complex cutting patterns

- Automatic loading and unloading system

Implementation Process

- Installation and setup completed within one week

- Two-week intensive training program for operators

- One month of process optimization, focusing on 28mm and 22mm tube cutting

- Integration into the existing production line for exhaust system components

Results and Improvements

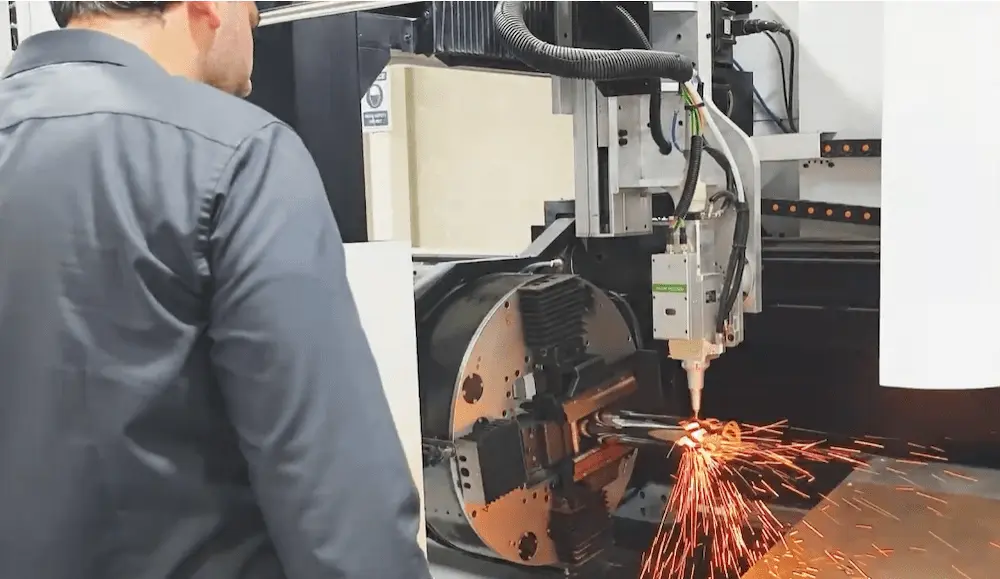

Precision and Quality

- Achieved cutting accuracy of ±0.1mm for 28mm and 22mm tubes

- Improved roundness and end face perpendicularity of cut tubes

- Reduced reject rate from 5% to less than 1% for exhaust system components

效率

- Cutting time for a standard exhaust pipe section reduced by 60%

- Daily production capacity increased by 80% for 28mm and 22mm tube components

- Simplified workflow with reduced need for secondary processing

Flexibility and Innovation

- Enabled rapid prototyping of new exhaust designs

- Facilitated the production of complex tube joints and bends

- Reduced new product development cycle by 40%

Cost Effectiveness

- Material utilization improved from 85% to 92%

- Energy consumption per part reduced by 30%

- Overall production costs decreased by 25% for tubular components

Client Feedback

The Production Manager stated: “The LX-GL40 has transformed our exhaust system production. The precision we now achieve with our 28mm and 22mm tubes has significantly improved the fit and performance of our final products. We’ve seen a notable reduction in assembly time and warranty claims related to exhaust leaks.”

He added, “The machine’s flexibility has been a game-changer for our R&D efforts. We can now quickly prototype and test new exhaust designs, which has accelerated our innovation cycle and helped us secure new contracts with major automotive manufacturers.”

Looking to the future, he commented, “Given the success we’ve had with the LX-GL40, particularly in our exhaust system line, we’re exploring its application in other areas of our production. The potential for customization and complex cutting patterns opens up new possibilities for light-weighting and performance optimization in various automotive components.”

สรุป

The implementation of the LX-GL40 laser tube cutting machine has significantly enhanced the Turkish manufacturer’s capabilities in producing high-precision automotive parts, particularly exhaust system components. By improving accuracy, efficiency, and design flexibility, the company has strengthened its competitive position in both domestic and European markets. The success of this implementation demonstrates the potential of advanced laser cutting technology in driving innovation and efficiency in the automotive supply chain.