Client Background

A leading door handle and hardware accessories manufacturer in Mexico, specializing in high-end products for both domestic and North American markets. With the rise of smart home technology, the company has been expanding into the electronic door lock market.

Challenges and Solutions

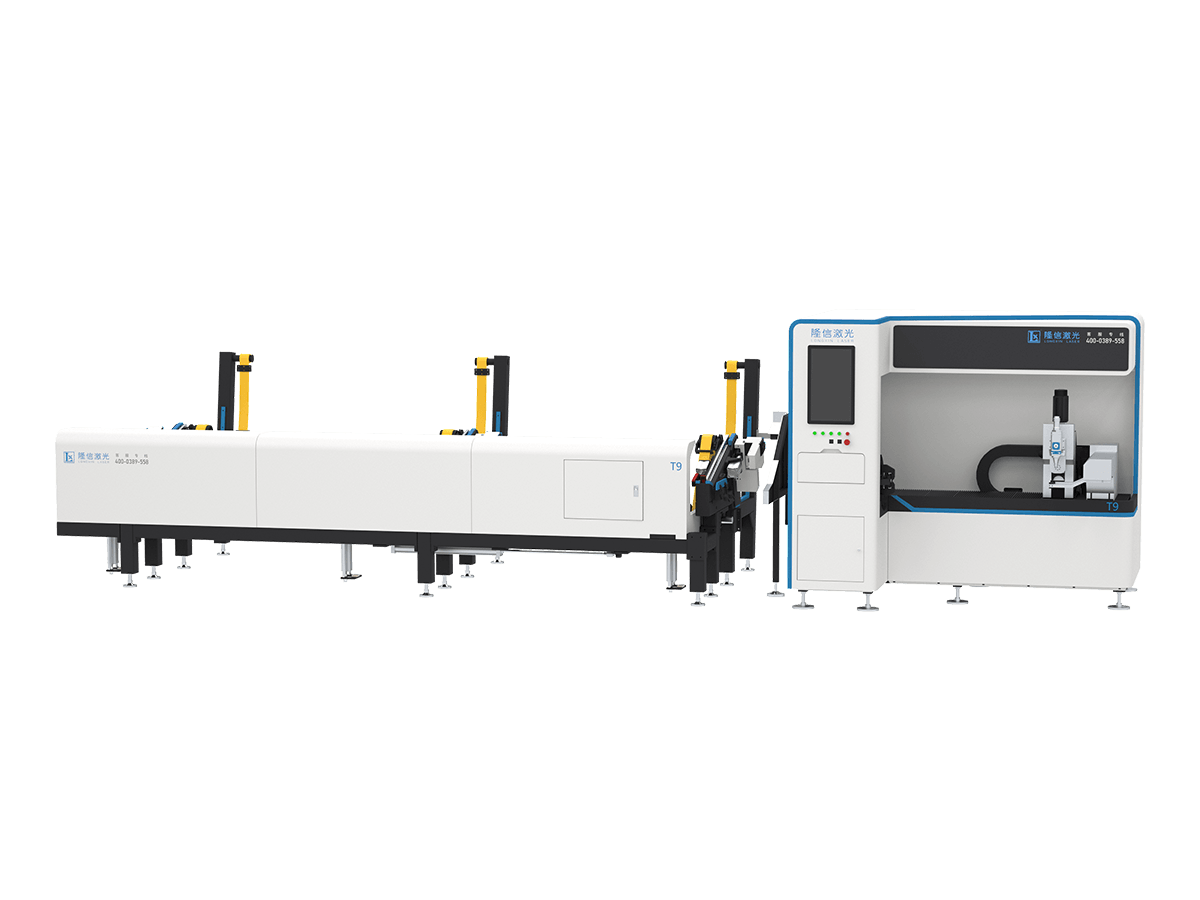

Facing increased demands for precision, efficiency, and product diversity, the company implemented the LX-T9 laser tube cutting machine from Longxin Laser. This advanced machine offers high-precision cutting for various pipe materials, including round pipes (Φ20-90mm), square pipes (▢15*15-60*60mm), and can process materials such as stainless steel, carbon steel, aluminum, copper, and iron.

Specific Processing Requirement

A key challenge for the manufacturer was the need for precise bevel cutting on 20mm diameter round tubes, crucial for the subsequent welding process in their door handle assembly. The LX-T9’s 45° bevel cutting capability was particularly well-suited to address this requirement.

Implementation Process and Results

Machine Integration and Optimization

- The LX-T9 was installed and initially calibrated within a week by Longxin Laser’s technical team.

- Five core operators underwent two weeks of intensive training on the new system.

- The first month was dedicated to fine-tuning cutting parameters, with special attention to optimizing the bevel cutting process for 20mm round tubes.

- The production line was reorganized to optimize workflow around the new machine, ensuring smooth transition from cutting to welding processes.

Performance Improvements

- Precision and Quality

- Achieved cutting accuracy of ±0.1mm for general cuts.

- For 20mm tube bevel cutting, consistently achieved a bevel angle accuracy of ±1°.

- Improved fit for welding, resulting in stronger joints and better aesthetics.

- Efficiency

- Bevel cutting time for 20mm tubes decreased from 2 minutes to 40 seconds.

- Daily output of beveled tubes ready for welding increased by 70%.

- Material Utilization

- Overall material utilization improved from 88% to 93%.

- Scrap rate for bevel-cut tubes reduced by 40%.

- Production Flexibility

- Reduced setup time for different tube sizes and materials by 60%.

- Enabled quicker transitions between various door handle designs.

These improvements led to a 25% increase in overall production capacity and a 15% reduction in production costs for door handle components.

Client Feedback

The Production Director stated: “The LX-T9 has revolutionized our production capabilities, especially in terms of precision bevel cutting for our 20mm tubes. This was a critical process for us, as it directly impacts the strength and quality of our welded joints in door handles.”

He further elaborated, “Before the LX-T9, we struggled with consistency in our bevel cuts. This led to variability in our welding process, sometimes resulting in weaker joints or visible imperfections. Now, with the LX-T9’s precise 45° bevel cutting capability, our welding process has become much more reliable. We’re seeing stronger joints, better aesthetics, and a significant reduction in post-weld finishing work.”

Regarding efficiency, he added, “The speed at which we can now produce accurately beveled tubes is remarkable. This has not only increased our overall output but also given us more flexibility in our production scheduling. We can respond to custom orders much more quickly now.”

Looking to the future, the director mentioned, “Given the success we’ve had with the LX-T9, particularly in improving our bevel cutting process, we’re planning to invest in additional units over the next year. We see this as a key part of our strategy to expand our product line, especially in the high-end door handle market where precision and quality are paramount.”

Kết luận

The implementation of the LX-T9 laser tube cutting machine has significantly enhanced the manufacturer’s capabilities in precision, efficiency, and product diversity. Its ability to perform accurate bevel cuts on 20mm tubes has been particularly transformative, improving both the quality and efficiency of the subsequent welding process. This has not only solved immediate production challenges but also positioned the company for future growth in the competitive smart home and high-end door handle markets.