Today’s pipe cutting projects, ranging from DIY plumbing to industrial manufacturing, demand specific tools based on pipe material, diameter, wall thickness, and working environment. From traditional manual tools to advanced laser systems, this guide compares eight effective pipe cutting tools to help you make an informed choice for your specific needs.

8 Best Tools for Steel Pipe Cutting

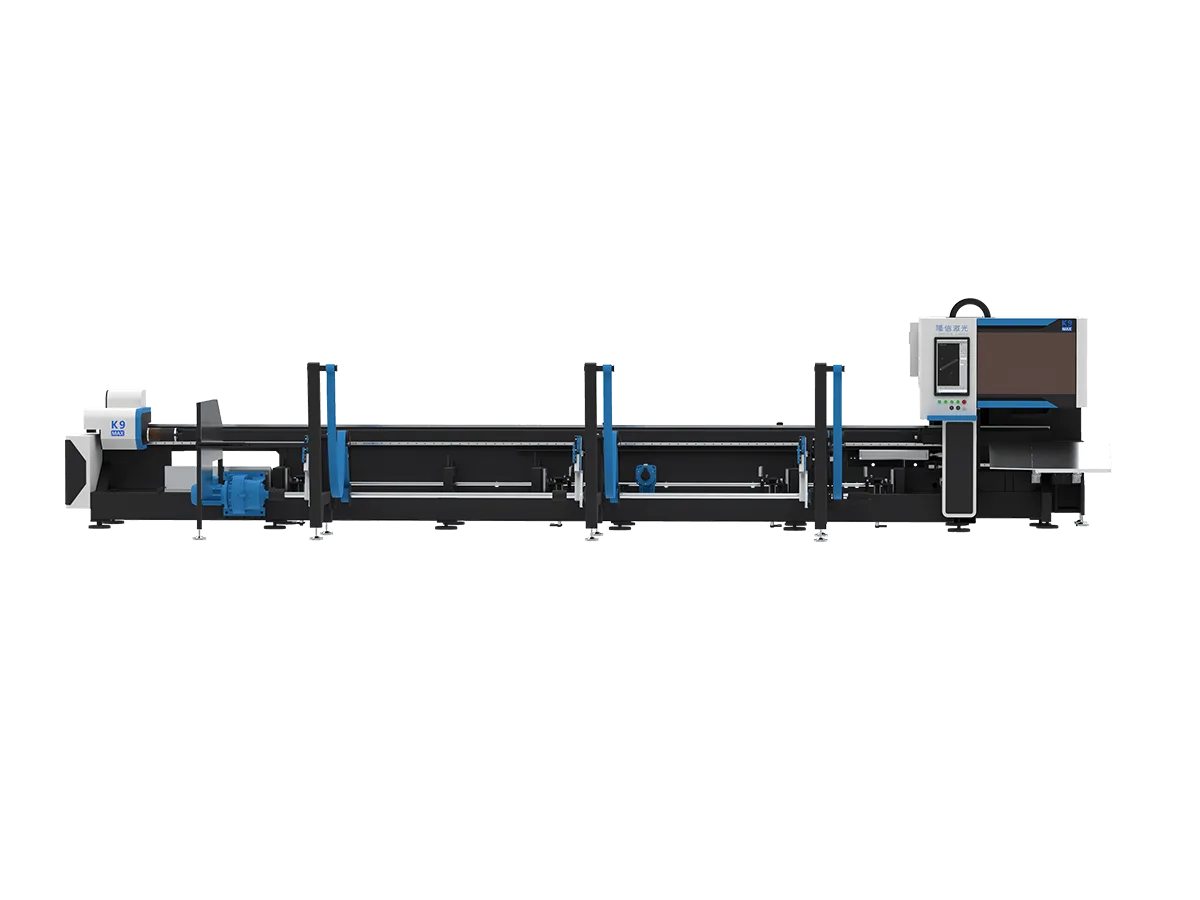

I. Steel Pipe Laser Cutting Machine

Modern laser cutting technology represents the pinnacle of precision pipe cutting solutions. These sophisticated machines utilize high-powered laser beams controlled by computer numerical systems (CNC) to deliver unmatched accuracy and efficiency in pipe cutting operations.

Advantages:

- Ultra-precise cutting with minimal material waste

- Exceptional cutting speed for high-volume production

- Ability to perform complex cuts and intricate designs

- Clean, burr-free edges requiring minimal post-processing

- Automated operation reducing labor costs

- Environmentally friendly with minimal waste generation

- Consistent quality across large production runs

Disadvantages:

- Significant initial investment required

- Requires specialized technical expertise

- Regular maintenance and calibration needed

- Large space requirements for installation

Best Applications:

- Large-scale industrial manufacturing

- Mass production facilities

- Complex pipe fabrication projects

- High-precision component manufacturing

II. Metal Cutting Bandsaw

A metal cutting bandsaw represents an essential industrial solution, offering a balance between precision and efficiency. These machines use a continuous metal band blade to cut through steel pipes.

Advantages:

- Can cut up to six tubes simultaneously

- Delivers clean, straight cuts with minimal burrs

- Suitable for projects of all sizes

- Relatively quiet operation

- No blade lubricant required

- Excellent for high-volume production

Disadvantages:

- Requires dedicated space for stationary models

- Cannot perform cuts on already-built structures

- Initial cost higher than manual tools

- Limited to straight cuts only

Best Applications:

- Production facilities

- Metal fabrication shops

- Construction material preparation

- Industrial manufacturing

III. Cold Saw

The cold saw specializes in precision cutting while keeping both blade and material cool during operation, resulting in superior cut quality.

Advantages:

- Produces clean, burr-free cuts

- Minimal heat generation during cutting

- Extended blade life due to cooling action

- Can cut multiple pipes simultaneously

- Leaves smooth finish requiring little post-processing

Disadvantages:

- Higher initial cost than conventional saws

- Requires fixed installation

- Slower cutting speed compared to alternatives

- Limited mobility

Best Applications:

- Precision metal fabrication

- High-end manufacturing

- Projects requiring exact measurements

- Professional metalworking shops

IV. Portable Bandsaw

A compact, handheld version of its larger counterpart, the portable bandsaw combines mobility with precision for on-site cutting needs.

Advantages:

- Excellent mobility and versatility

- Suitable for existing structures

- Moderate noise level

- Ergonomic design

- Effective in hard-to-reach areas

- Lightweight and easy to handle

Disadvantages:

- Can only cut one tube at a time

- May result in crooked cuts without proper support

- Limited cutting capacity

- Battery life constraints for cordless models

Best Applications:

- On-site construction work

- Maintenance and repair

- Tight space operations

- Field work

V. Reciprocating Saw

The reciprocating saw offers a powerful solution for quick cutting needs, especially in demolition or renovation scenarios.

Advantages:

- Highly portable

- Versatile cutting capabilities

- Good for tight spaces

- Quick cutting speed

- Cordless options available

- Cost-effective

Disadvantages:

- Less precise than other methods

- High vibration and noise

- Difficult to maintain straight cuts

- Frequent blade changes needed

- Not suitable for finish work

Best Applications:

- Demolition work

- Quick rough cuts

- Emergency repairs

- Renovation projects

VI. Angle Grinder

An angle grinder equipped with cutting discs provides a versatile solution for pipe cutting, particularly effective for smaller diameter pipes.

Advantages:

- Highly versatile tool

- Quick cutting speed

- Portable and easy to use

- Affordable

- Can make flush cuts

- Works in tight spaces

Disadvantages:

- Generates sparks and debris

- Less precise than dedicated pipe cutters

- Frequent disc replacement needed

- Safety concerns

- Noisy operation

Best Applications:

- Small diameter pipes

- Quick cuts

- General construction

- Home DIY projects

VII. Manual Tube Cutter

Traditional manual tube cutters offer a simple yet effective solution for precise cuts on smaller pipes, making them ideal for plumbing work.

Advantages:

- Clean, precise cuts

- No power required

- Highly portable

- Silent operation

- Minimal maintenance needed

- Very safe to use

- Cost-effective

Disadvantages:

- Labor intensive

- Limited to smaller pipe diameters

- Time-consuming for multiple cuts

- Not suitable for heavy-duty work

- Requires physical effort

Best Applications:

- Small plumbing projects

- DIY work

- Precision cutting needs

- Light commercial use

- Maintenance tasks

VIII. Hacksaw

The traditional hacksaw remains a reliable and accessible tool for basic pipe cutting needs.

Advantages:

- Very affordable

- Simple to use

- No power needed

- Highly portable

- Minimal maintenance

- Works anywhere

- No special training required

Disadvantages:

- Very labor intensive

- Slow cutting speed

- Can produce uneven cuts

- Limited to smaller pipes

- Physically demanding

Best Applications:

- Basic DIY projects

- Emergency repairs

- Small-scale work

- Budget-conscious users

- Simple cutting tasks

Comprehensive Tool Comparison

| Tool Type | Cutting Speed | Material Compatibility | Precision | Cost Range* | Ease of Use | Mobility | Noise Level | Maintenance Needs |

|---|---|---|---|---|---|---|---|---|

| Laser Cutting Machine | Very High (5/5) | All metals, thick & thin (5/5) | Excellent (5/5) | $$$$ | Complex (2/5) | Fixed (1/5) | Low (4/5) | High (1/5) |

| Metal Cutting Bandsaw | High (4/5) | Most metals (4/5) | Very Good (4/5) | $$$ | Moderate (3/5) | Limited (2/5) | Moderate (3/5) | Moderate (3/5) |

| Cold Saw | Moderate (3/5) | All metals (5/5) | Very Good (4/5) | $$$ | Moderate (3/5) | Fixed (1/5) | Moderate (3/5) | Moderate (3/5) |

| Portable Bandsaw | Moderate (3/5) | Most metals (4/5) | Good (3/5) | $$ | Good (4/5) | Excellent (5/5) | High (2/5) | Moderate (3/5) |

| Reciprocating Saw | High (4/5) | Most metals (3/5) | Fair (2/5) | $$ | Very Good (4/5) | Excellent (5/5) | Very High (1/5) | Low (4/5) |

| Angle Grinder | High (4/5) | Most metals (3/5) | Fair (2/5) | $ | Good (4/5) | Very Good (4/5) | Very High (1/5) | Moderate (3/5) |

| Manual Tube Cutter | Low (1/5) | Thin-walled only (2/5) | Very Good (4/5) | $ | Very Good (4/5) | Excellent (5/5) | Silent (5/5) | Low (4/5) |

| Hacksaw | Very Low (1/5) | Most metals (3/5) | Good (3/5) | $ | Very Good (4/5) | Excellent (5/5) | Silent (5/5) | Very Low (5/5) |

*Cost Range Legend:

- $ = Under $100

- $$ = $100-$500

- $$$ = $500-$5,000

- $$$$ = Over $5,000

Additional Comparison Factors:

Power Source Requirements:

- Electric (High Power): Laser Cutter, Metal Cutting Bandsaw, Cold Saw

- Electric (Standard): Portable Bandsaw, Reciprocating Saw, Angle Grinder

- Manual: Tube Cutter, Hacksaw

Best Use Case Scenarios:

- Industrial Production: Laser Cutter, Metal Cutting Bandsaw, Cold Saw

- Construction Sites: Portable Bandsaw, Reciprocating Saw, Angle Grinder

- Small Projects/DIY: Manual Tube Cutter, Hacksaw

Cut Quality Characteristics:

- Laser Cutter: Perfect edges, no burrs, heat-affected zone

- Bandsaws: Clean cuts, minimal burrs

- Cold Saw: Very clean cuts, minimal deformation

- Power Tools: Rougher cuts, may need finishing

- Manual Tools: Clean cuts but requires skill

Production Volume Capacity:

- High Volume: Laser Cutter, Metal Cutting Bandsaw

- Medium Volume: Cold Saw, Portable Bandsaw

- Low Volume: Reciprocating Saw, Angle Grinder

- Very Low Volume: Manual Tube Cutter, Hacksaw

Making the Right Choice: Key Considerations

Project Scale

- Large Industrial: Consider laser cutting machines or metal cutting bandsaws

- Medium Commercial: Cold saws or portable bandsaws are ideal

- Small Projects/DIY: Manual tube cutters or hacksaws will suffice

Budget Considerations

- High Budget: Laser cutters, cold saws

- Medium Budget: Bandsaws, power tools

- Limited Budget: Manual tools, basic power tools

Usage Frequency

- Daily Use: Invest in professional-grade power tools or industrial machines

- Occasional Use: Mid-range power tools

- Rare Use: Manual tools or basic power tools

Precision Requirements

- High Precision: Laser cutters, cold saws

- Medium Precision: Bandsaws, manual tube cutters

- Basic Precision: Reciprocating saws, angle grinders

Conclusion: Choosing the Right Steel Pipe Cutter

The ideal choice for cutting steel pipes ultimately depends on your specific needs, working environment, and budget constraints. Here’s a simplified guide for different scenarios:

For Industrial Applications:

- If precision and high volume are priorities, and budget allows, the laser cutting machine is unmatched

- For regular production needs, a metal cutting bandsaw or cold saw offers the best balance of efficiency and cost

- When working on-site, a portable bandsaw provides the necessary mobility without sacrificing too much precision

For Professional Contractors:

- Portable bandsaws and reciprocating saws offer the mobility needed for field work

- Angle grinders work well for quick cuts and tight spaces

- Manual tube cutters are excellent for precise, clean cuts in plumbing applications

For DIY and Small Projects:

- Manual tube cutters provide the best value for occasional use

- Hacksaws are perfectly adequate for basic cutting needs

- An angle grinder can be a versatile addition to your toolbox

Remember that investing in quality tools appropriate for your specific needs will save time, reduce waste, and produce better results in the long run. Consider factors such as frequency of use, required precision, mobility needs, and available budget when making your final decision.

To get the most out of your chosen tool, always follow manufacturer guidelines, maintain your equipment properly, and prioritize safety in your working environment. With the right tool and proper technique, you can achieve professional-quality cuts regardless of your chosen method.