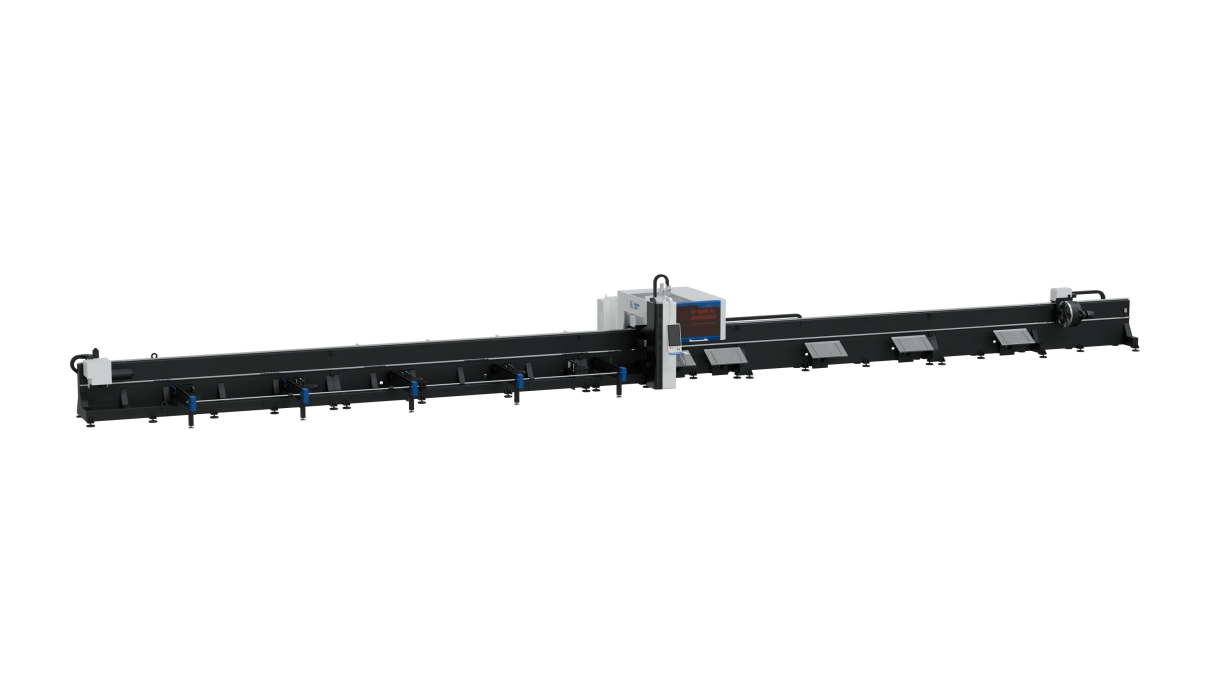

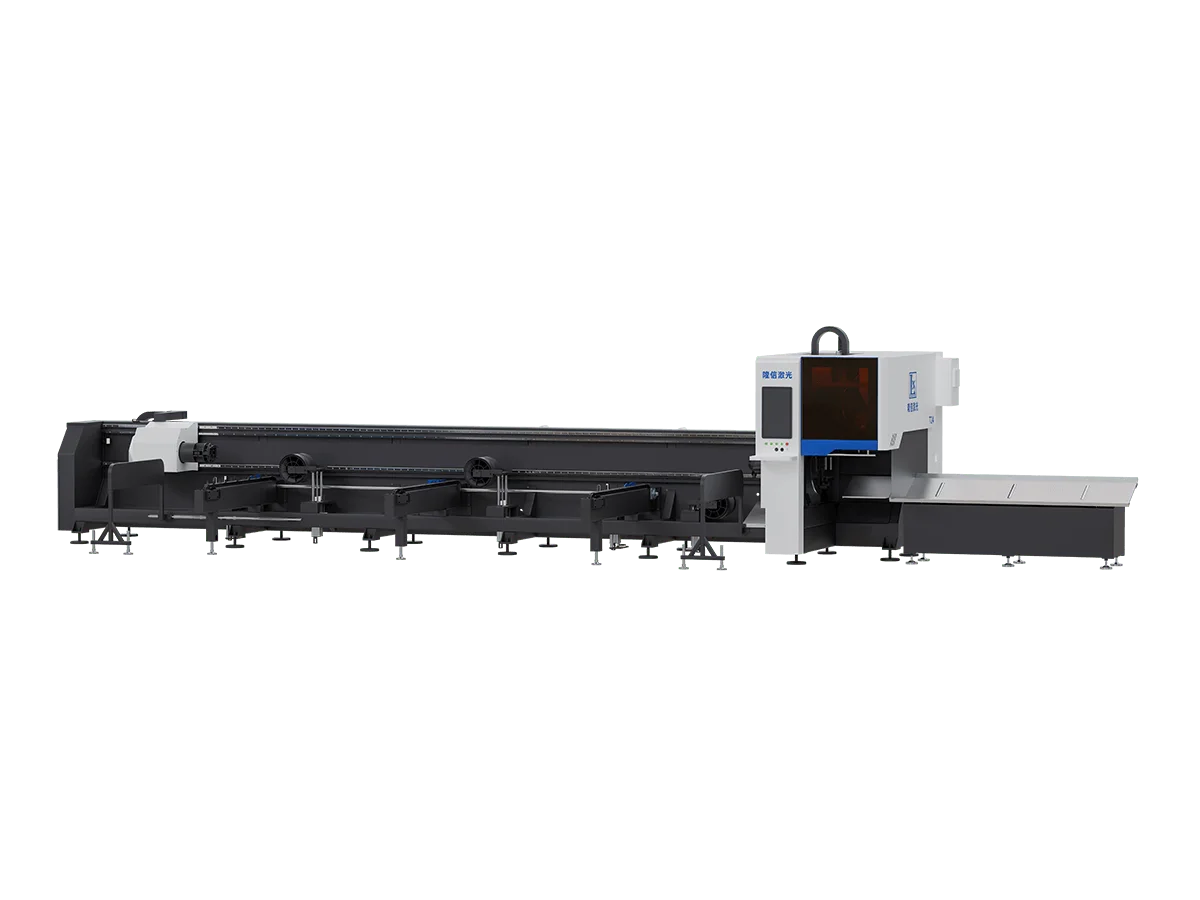

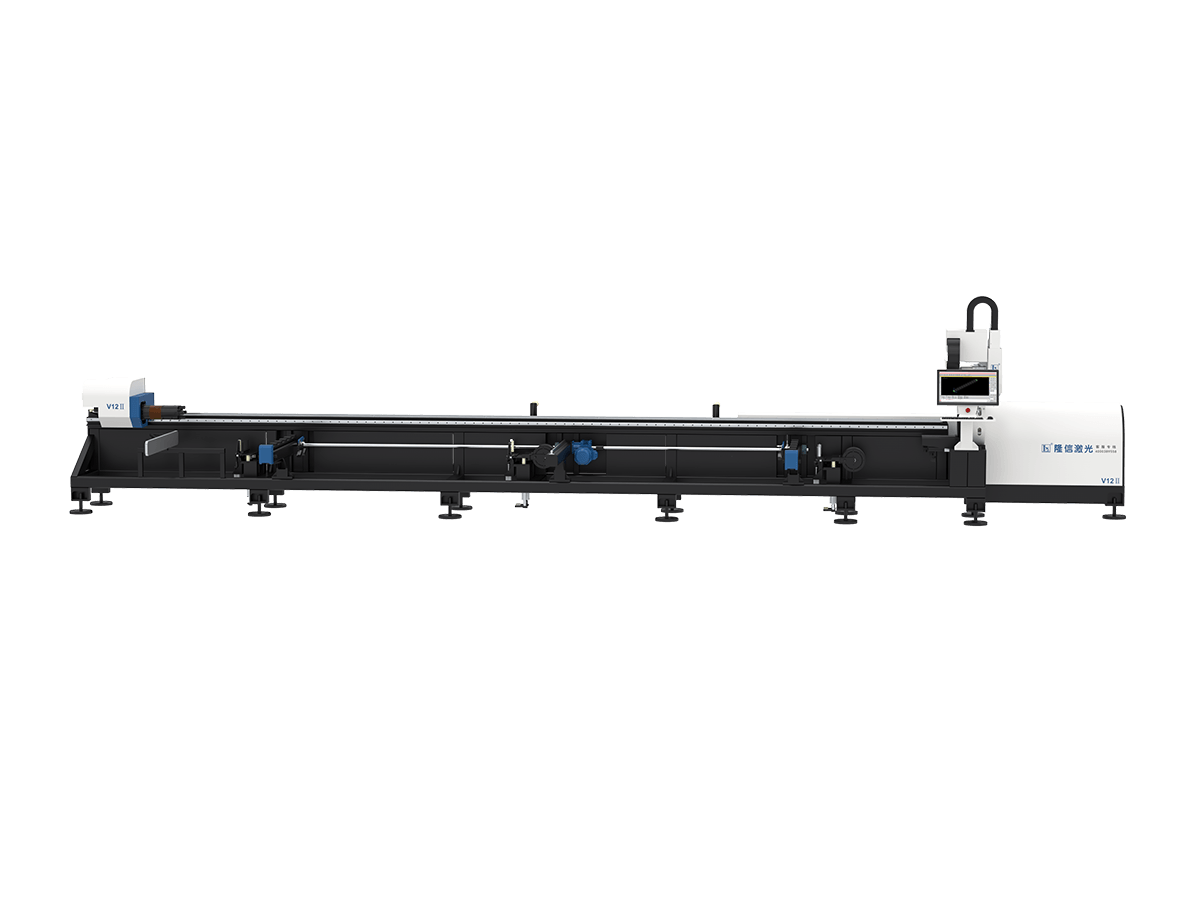

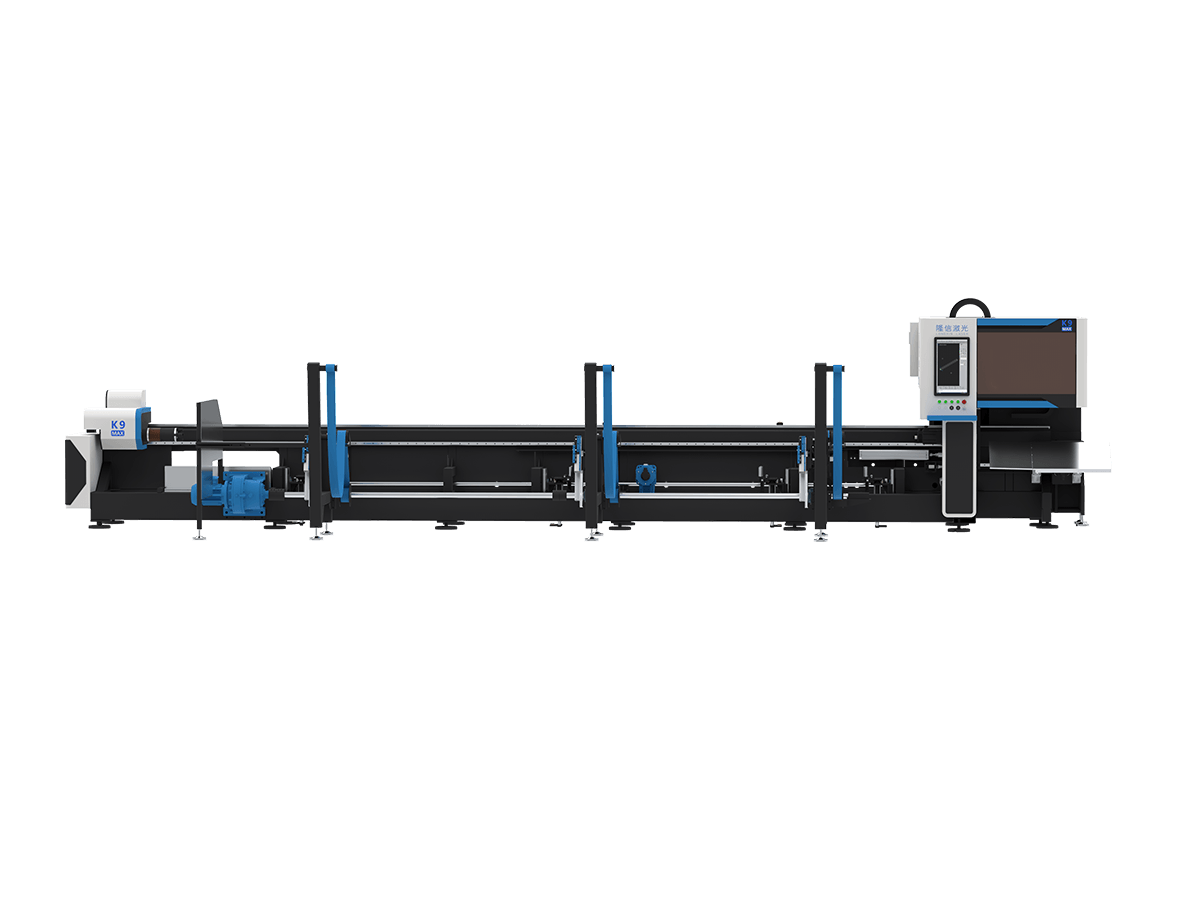

2.0G Ultra High-speed Pipe Laser Cutting Machine

LX-K9MAX

- One machine for two machines, maximum chuck speed 230 rpm

- Maximum acceleration 2.0G, fast cutting speed

- Optional follow-up loading and unloading/pneumatic loading and unloading

Product Features

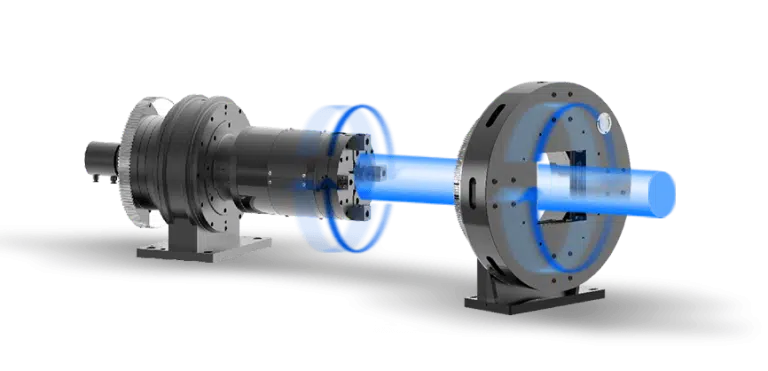

Versatile Pneumatic Chuck

Seamlessly transition between cutting requirements of various material and shapes without interruption.

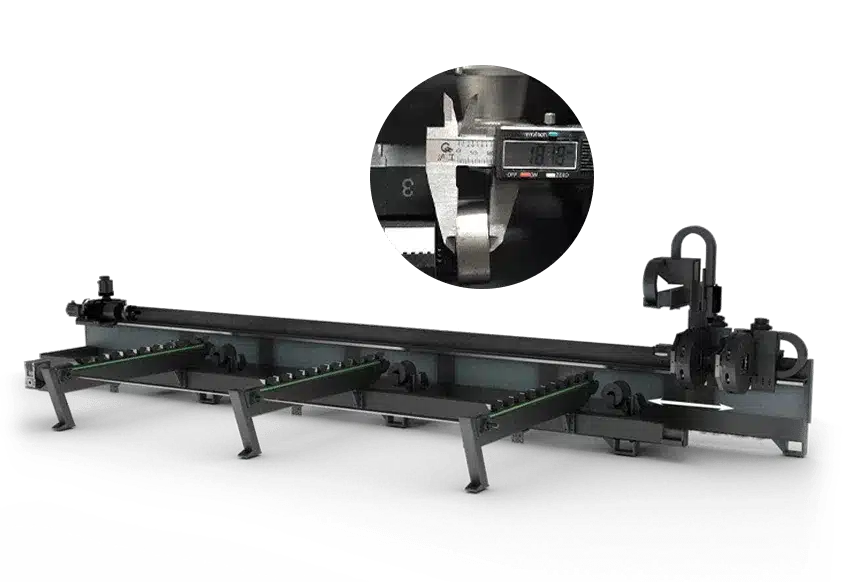

Minimized Waste, Maximized Savings

The unique mobile front chuck design allow the laser head to cut between the two chucks, reaching minimum tailing of 40 mm.

Economical but powerful

Unique design on key conponents and machine frame, reaching high cost-effective.

-拷贝.png.webp)

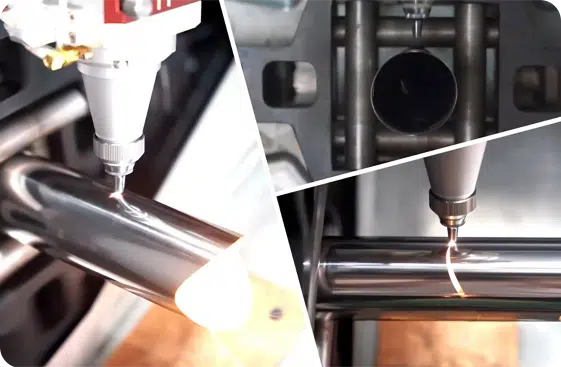

Specifically tailored for tiny tube cutting

The machanical design and the controller of this machine are with unique design for tiny tube cutting.

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Video

Cutting Samples

Automation Solutions

Automated pipe cutting and bending production line

Automatic cutting of bent pipe cutting line

Fully automatic pipe manufacturing online cutting chamfering welding line

Cookware pipe material processing production line

Customer Case

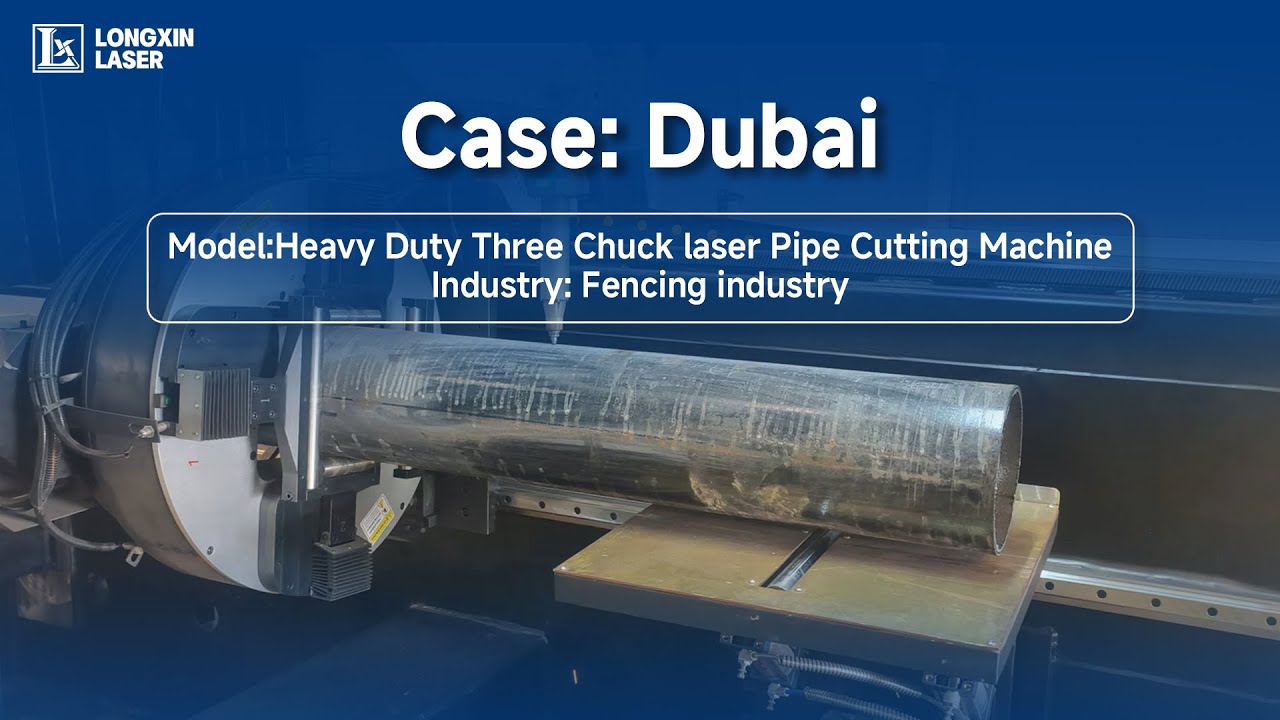

Customer Case: Dubai – High-Power Tube Laser Cutting for the Fencing Industry

Automated High‑Speed Tube Cutting & Chamfering in Türkiye

Longxin Laser Pipe Cutting Machine K9max Helps Indonesia’s Metal Pipe Industry Upgrade Automation

Racing Ahead: Transforming Bracket Manufacturing – Longxin laser

Longxin laser tube cutting machine helps Turkish customers complete furniture production

Streamlining Automotive Parts Production with Longxin Laser Technology