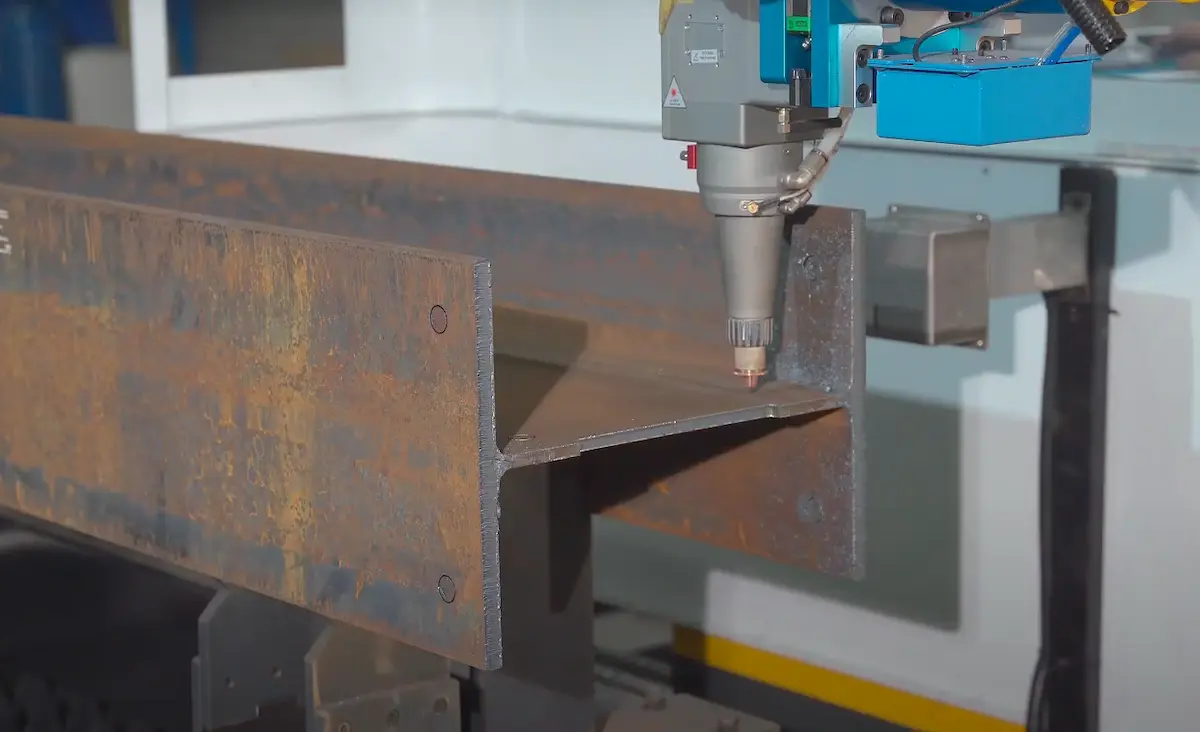

Laser tube cutting machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. However, despite their widespread use and proven benefits, several misconceptions about these machines persist. In this article, we aim to debunk seven common myths surrounding laser tube cutting machines.

Myth 1: Laser Tube Cutting Machines Are Only Suitable for Thin Materials

Reality: One of the most prevalent myths about laser tube cutting machines is that they are only effective for cutting thin materials. In fact, modern laser tube cutting machines can handle a wide range of materials and thicknesses, including thick-walled tubes and pipes. With advancements in laser technology and machine design, these machines can achieve high-quality cuts on various materials, from stainless steel and aluminum to brass and copper.

Myth 2: Laser Tube Cutting Machines Are Slow

Reality: While it’s true that laser cutting may appear slower than other cutting methods such as plasma cutting for certain applications, laser tube cutting machines have significantly improved their processing speeds over the years. With advancements in laser power, cutting head design, and motion control systems, modern laser tube cutting machines can achieve impressive cutting speeds while maintaining precision and accuracy.

Myth 3: Laser Tube Cutting Machines Are Expensive to Operate

Reality: Although the initial investment in a laser tube cutting machine may seem substantial, the long-term operational costs can be competitive compared to other cutting methods. Laser tube cutting machines offer high efficiency, minimal material waste, and reduced setup times, resulting in lower overall production costs. Additionally, the versatility of laser cutting technology allows manufacturers to handle a wide range of projects with a single machine, maximizing its return on investment.

Myth 4: Laser Tube Cutting Machines Produce Poor Edge Quality

Reality: Another common misconception is that laser tube cutting machines produce rough or poor-quality edges. On the contrary, laser cutting technology enables precise and clean cuts with minimal heat-affected zones, resulting in high-quality edges that often require minimal post-processing. With proper machine calibration and optimization, manufacturers can consistently achieve smooth and burr-free edges on a variety of materials.

Myth 5: Laser Tube Cutting Machines Are Difficult to Maintain

Reality: While laser tube cutting machines are sophisticated pieces of equipment, modern systems are designed with user-friendly interfaces and automated maintenance features to streamline operation and minimize downtime. Routine maintenance tasks, such as lens cleaning and alignment checks, can typically be performed quickly and easily by trained operators. Additionally, many manufacturers offer comprehensive support and service packages to ensure optimal machine performance and reliability.

Myth 6: Laser Tube Cutting Machines Are Hazardous to Operators

Reality: Safety is paramount in any manufacturing environment, and laser tube cutting machines are no exception. While lasers can pose potential hazards if not properly controlled, modern laser cutting systems incorporate numerous safety features, including protective enclosures, interlocks, and safety sensors, to minimize the risk of accidents. Additionally, operators receive extensive training on laser safety protocols and best practices to ensure safe operation.

Myth 7: Laser Tube Cutting Machines Are Only Suitable for Mass Production

Reality: While laser tube cutting machines excel in high-volume production environments, they are also well-suited for prototyping, custom fabrication, and small-batch manufacturing. With their rapid setup times, flexible programming capabilities, and high cutting speeds, laser tube cutting machines offer manufacturers the versatility to efficiently produce a wide range of parts and components, regardless of batch size.

Myth 8: Laser Tube Cutting Machines Are Limited in Geometry

Reality: Some believe that laser tube cutting machines are restricted to cutting only straight lines or simple shapes. However, modern laser tube cutting machines are equipped with advanced CNC control systems and 3D cutting capabilities, allowing for the creation of complex geometries, including bevels, miters, and intricate patterns. With multi-axis cutting heads and sophisticated software, these machines can accurately follow intricate designs and produce highly precise cuts on curved and irregular surfaces.

Myth 9: Laser Tube Cutting Machines Are Environmentally Harmful

Reality: There’s a misconception that laser tube cutting machines contribute significantly to environmental pollution due to their use of high-powered lasers and consumables like assist gases. However, laser cutting is inherently a more environmentally friendly process compared to traditional cutting methods such as plasma or waterjet cutting. Laser cutting produces minimal waste material, consumes less energy, and emits fewer harmful emissions. Additionally, advancements in laser technology have led to the development of eco-friendly assist gases and recycling systems, further reducing the environmental impact of laser tube cutting operations.

Myth 10: Laser Tube Cutting Machines Require Extensive Programming Knowledge

Reality: While programming skills are essential for maximizing the capabilities of laser tube cutting machines, the notion that extensive programming knowledge is always required is a myth. Many modern laser cutting systems feature intuitive CAD/CAM software with user-friendly interfaces and pre-programmed cutting parameters, allowing operators to create and modify cutting programs with minimal training. Additionally, manufacturers often provide comprehensive training and support resources to help operators learn the basics of machine programming and optimize their workflow. With practice and guidance, operators can quickly become proficient in programming laser tube cutting machines to meet their specific production needs.