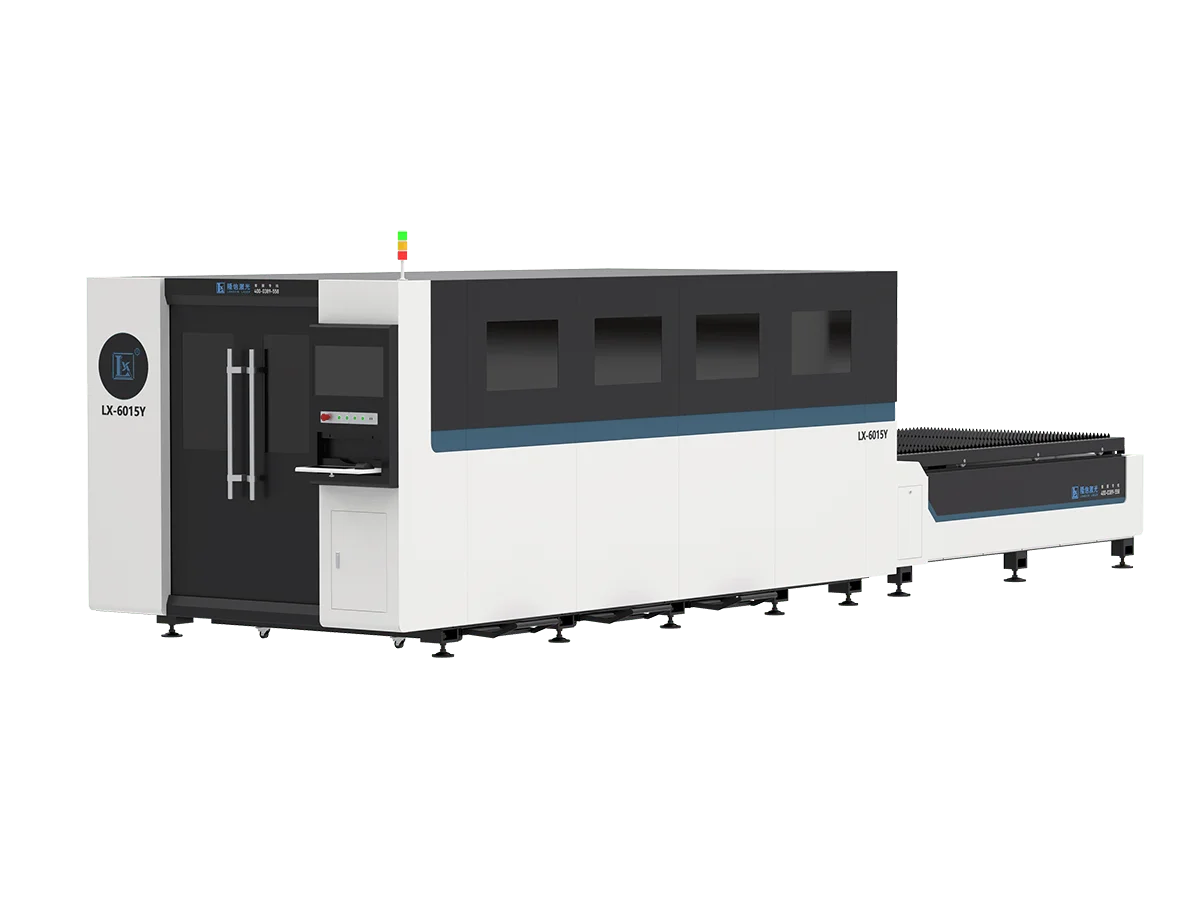

Laser cutting machine for sheets

LX-6025X

Video

Technical Parameters

- Model:

- Laser power:

- Working sheet

- X-Axis Travel

- Y-Axis Travel

- Z-Axis Travel

- XY motion accuracy

- Repeat Position Angle

- Working speed

- Acceleration

- Power demand

- Machine weight

- Apparent size

Intelligent Autofocus Cutting Head

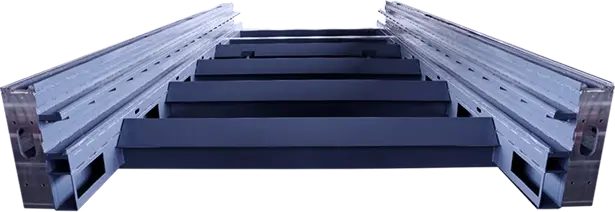

High-Rigidity Bed Base

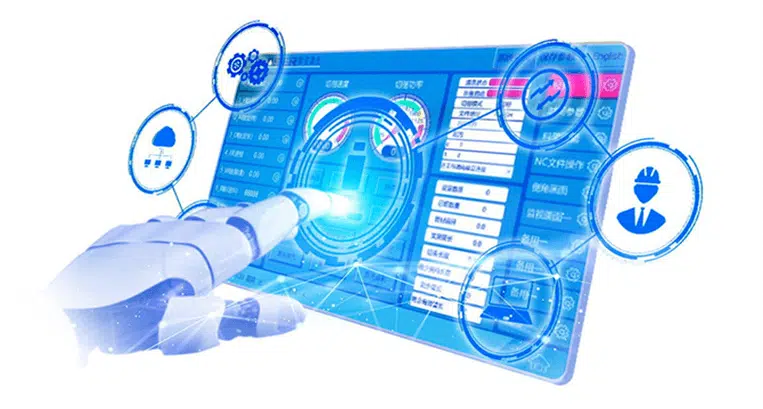

Intelligent Cutting System

The Intelligent Cutting System is a high-end solution designed for fiber laser cutting, offering stability, reliability, easy deployment, and excellent performance. It supports modular, customizable, and automated solutions, featuring functions like multi-level perforation for thick plates, intelligent tool retraction for smooth cuts, automatic edge detection for precise positioning, flying cutting for increased speed, and intelligent nesting to reduce material waste. This makes it one of the most advanced and efficient laser cutting systems available.

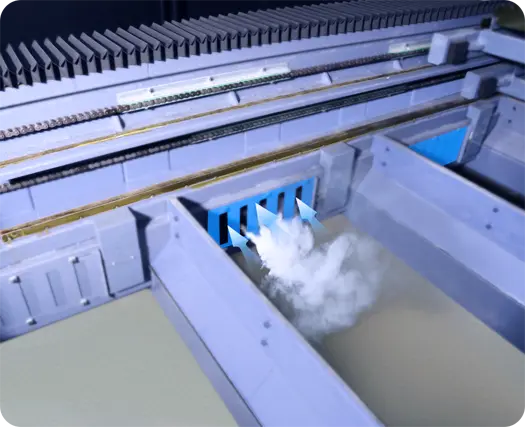

High-Efficiency Zoned Exhaust System

The cutting area is divided into multiple zones, each automatically opening as the cutting head moves over it, providing powerful and focused suction. Equipped with large exhaust channels, the system ensures smooth smoke extraction, making the process more environmentally friendly and clean.

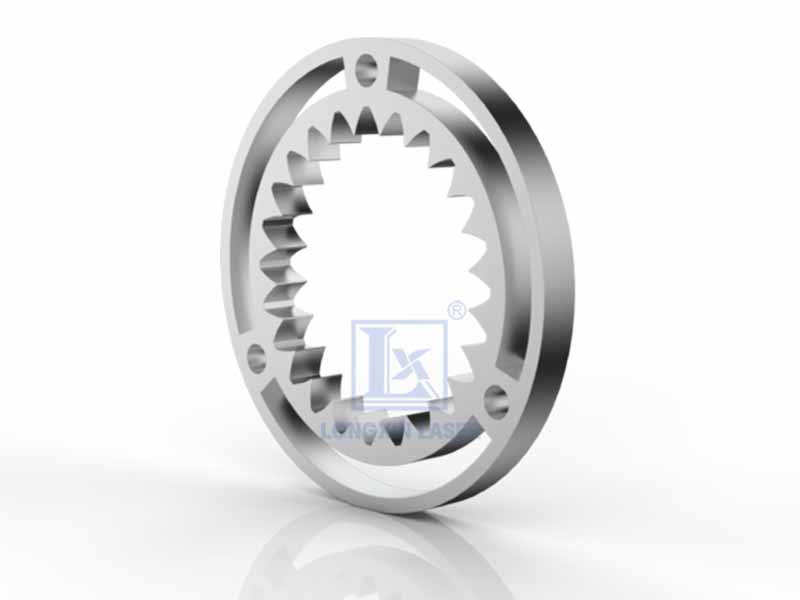

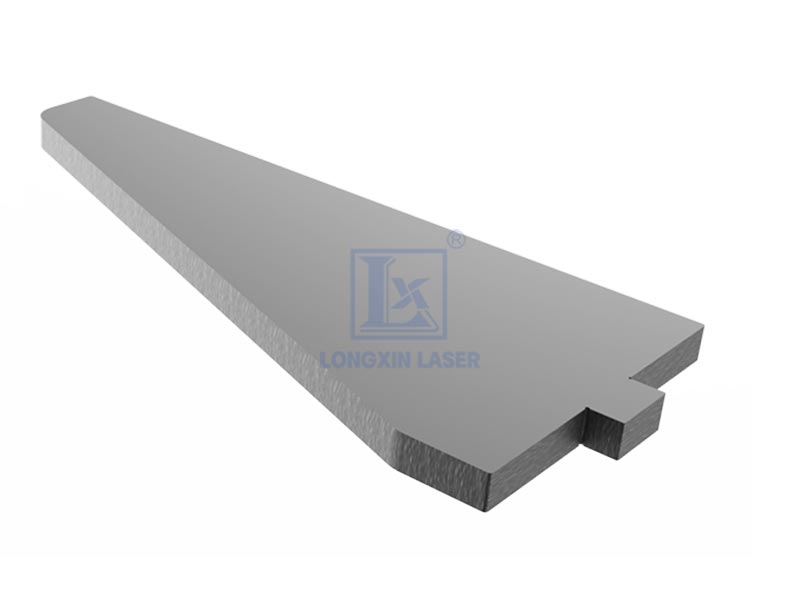

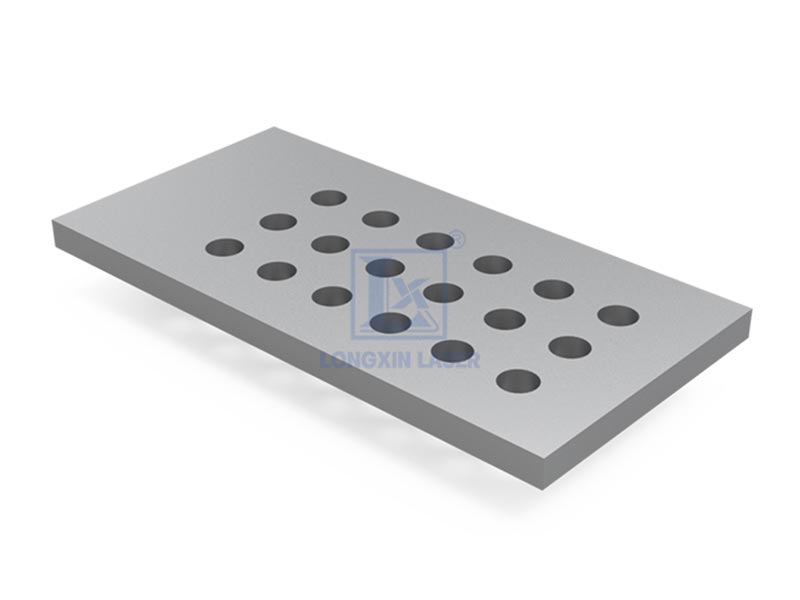

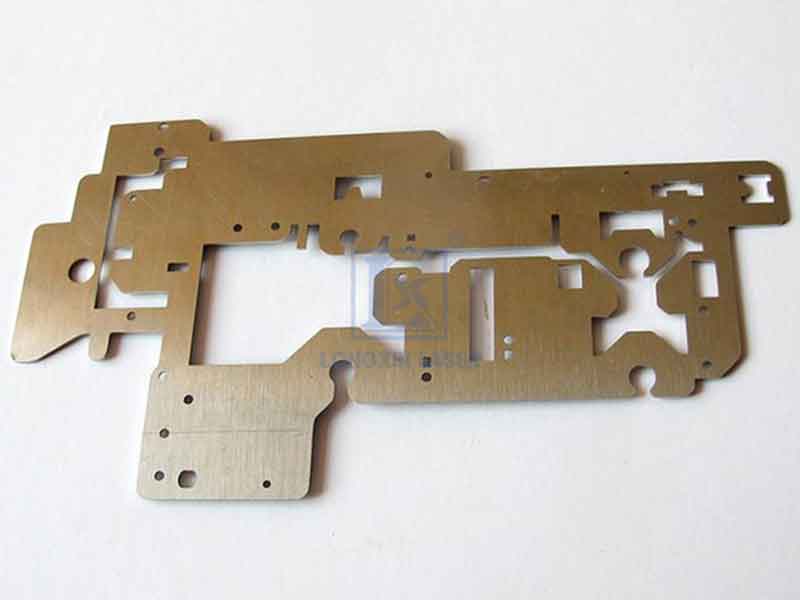

Cutting Samples

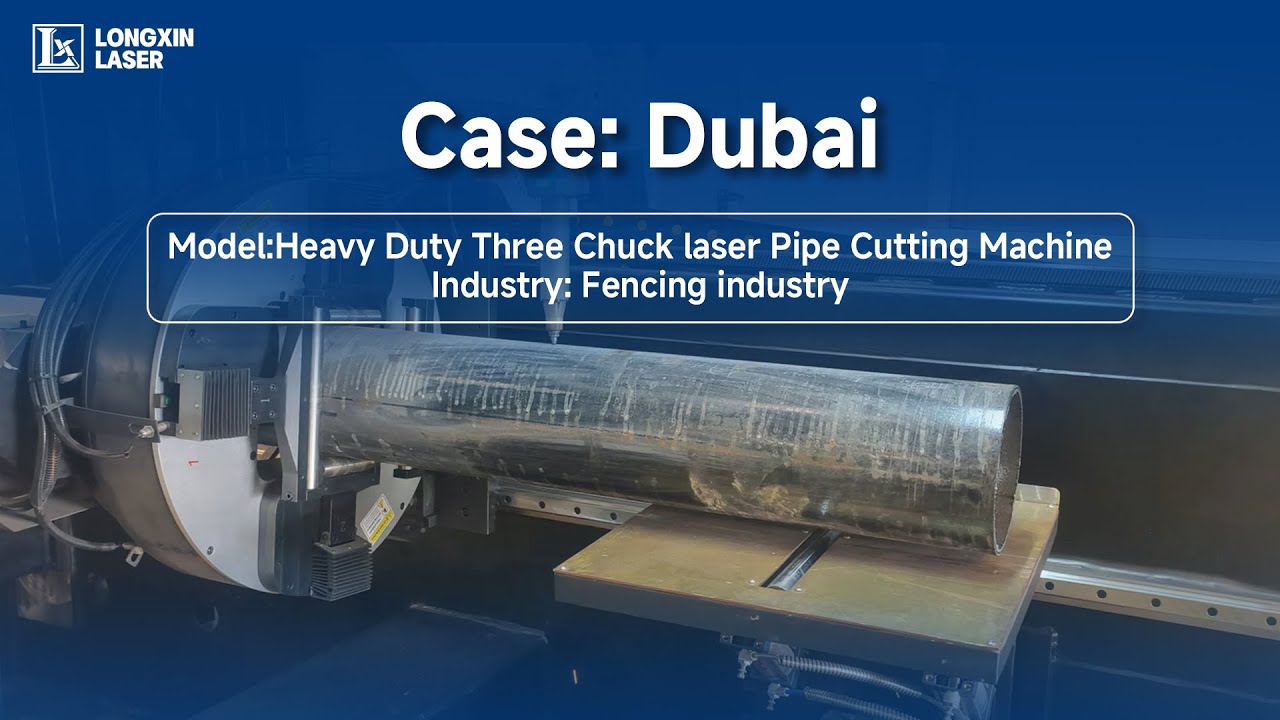

Customer Case

Reliable Quality with International Certifications