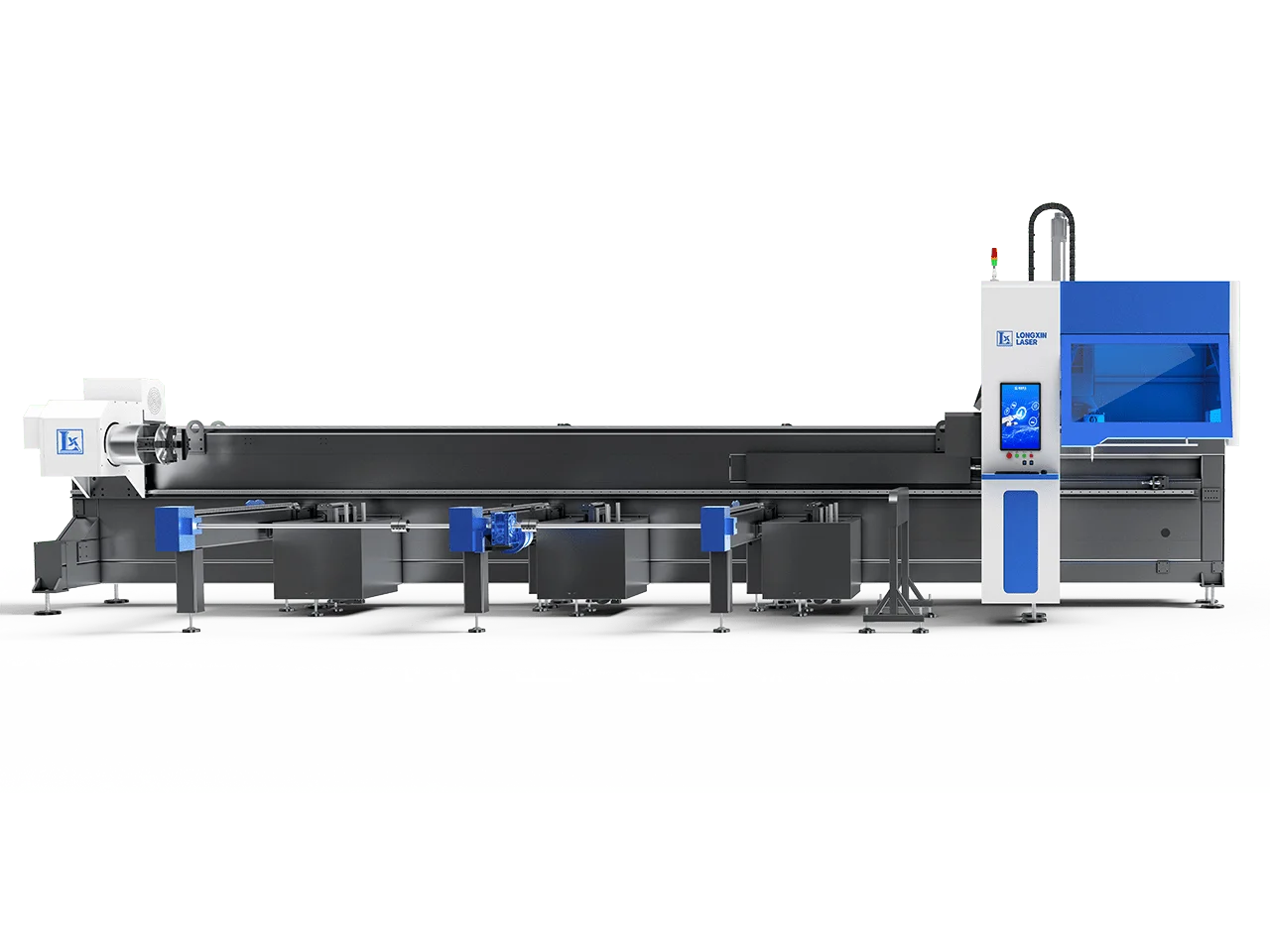

3 chucks heavy duty fiber laser pipe cutting machine

LX-K35-3

- Side-mounted bed frame for stability and efficiency

- Precision square-hole chuck: Expands square tube processing range (optional standard chuck available)

- Follow-up support: Effectively prevents workpiece deformation caused by tube sagging, improving cutting accuracy

- Zero tail material under applicable cutting conditions

- Ideal for large tube processing: Round tube: ∅40-350mm, Square tube: □40×40-350×350mm; Single tube load capacity: 1000kg

- Bevel cutting head (optional)

Product Features

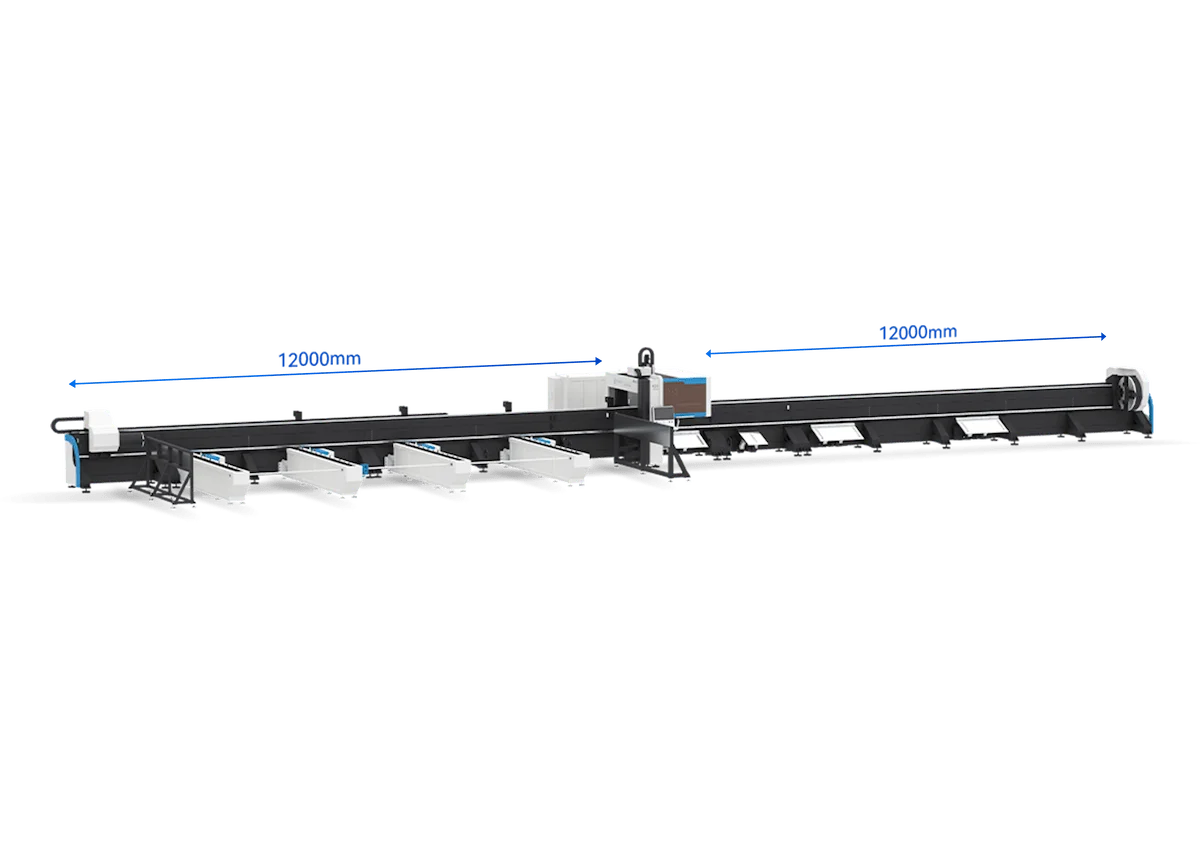

Loading range

Loading range: 12000mm, Unloading range: 12000mm. One time loading pipe: ≤3pcs.

Segmented side-mounted bed design

According to the factory floor space and the actual production needs of free choice of loading and unloading. Length of the optional specifications of the upper material: 6 metres, 9 metres, 12 metres; optional specifications of the lower material: 3 metres, 6 metres, 9 metres, 12 metres.

Fully automatic tube loading in rows

Automatic push tube loading loading, greatly improve the loading efficiency

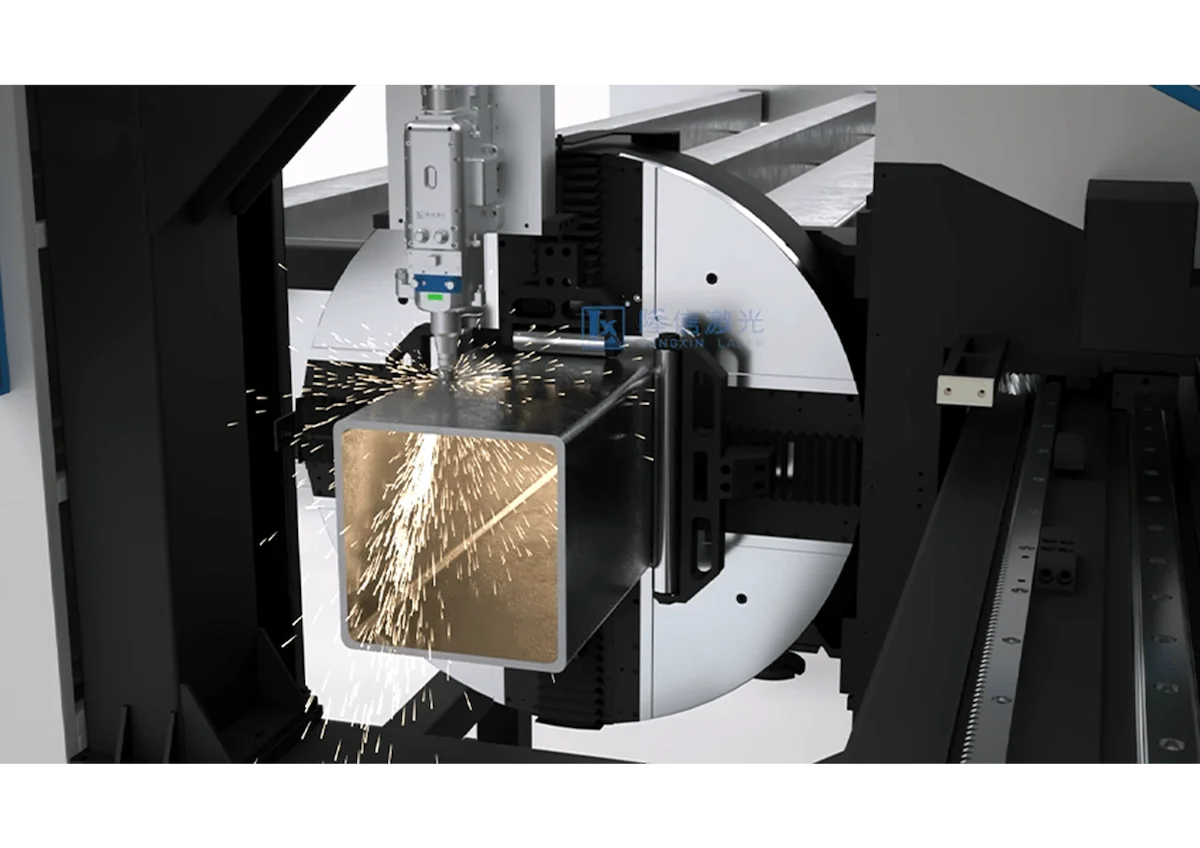

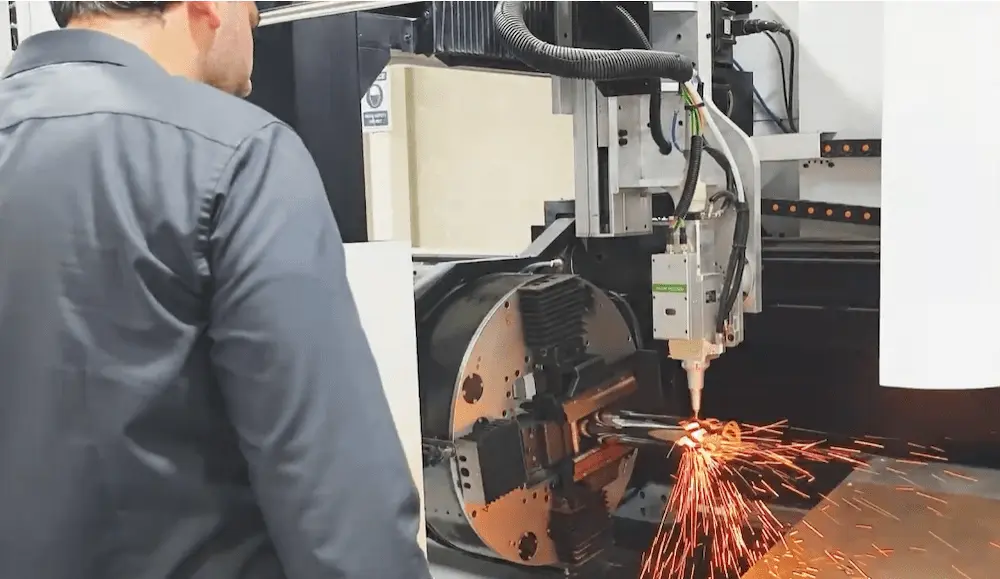

Full stroke three chuck clamping

The three-chuck system in laser tube cutting machines enhances precision and stability for large, heavy tubes, enabling zero-tailing cuts, superior material utilization, high efficiency, deformation correction, and versatile handling of diverse tube shapes, boosting productivity and quality.

Full stroke square hole chuck

Weighing up to 1000KG per tube, the processing range is larger than that of a circular chuck.

Technical Parameters

- Model:

- Laser power:

- Cutting Diameter Of Round Tube:

- Cutting Diameter Of Square Tube:

- Cutting Tube length:

- Accuracy Of Processing:

- Dimensions:

- Weight:

- Cutting Tube Type:

- Cutting Material:

Video

Need more information? Contact us today and we can set up a confidential meeting to discuss your project.

Reliable Quality with International Certifications

Our certificates that demonstrate the quality, reliability, and compliance of our products with international standards.

Cutting Samples

Customer Case

Korea’s Leading Steel Structure Manufacturer Upgrades Production with Longxin Laser LX-T35 Three-Chuck Bevel Tube Cutting Machine

How Longxin LX-K24 3D Laser Tube Cutting Machine Boosted Jinjia Building Materials’ Productivity by 20%

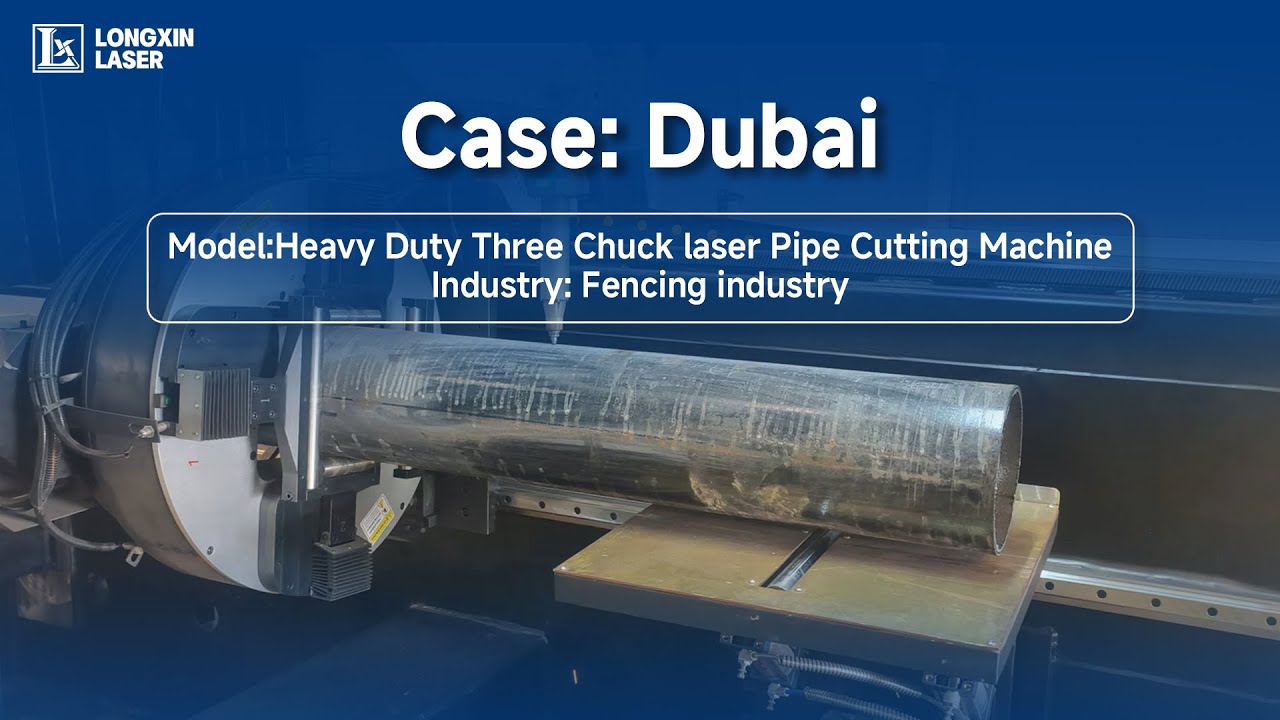

Dubai Construction Client Boosts Productivity with Longxin LX-K28 Three-Chuck Laser Tube Cutting Machine

Longxin Laser Machine LX-K6 in South Africa

Bed frame laser pipe cutting machine production line case study

Customer Case: Dubai – High-Power Tube Laser Cutting for the Fencing Industry

Automated High‑Speed Tube Cutting & Chamfering in Türkiye

Longxin Laser Pipe Cutting Machine K9max Helps Indonesia’s Metal Pipe Industry Upgrade Automation

Racing Ahead: Transforming Bracket Manufacturing – Longxin laser

Why longxin laser?

Cutting-edge technology

We utilize the most advanced laser tube cutting technology to ensure precision and high quality in every product.

Extensive experience

With 15+ years tube cutting experience, we understand what your needs.

Efficient Production

Our production line runs efficiently, producing over 300+ machines per month.

Custom automation

We offer a specialised, bespoke service to meet your needs.

Customer Support

Our dedicated after-sales service team is always ready to assist you

Smart software

Highly integrated intelligent tube cutting solutions

Related Products

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.

Request a quote

Please fill in the following form to contact us and provide us with your requirements. We will get back to you within 24 hours.